Abstract

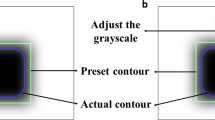

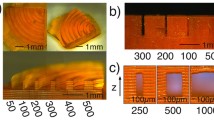

The recent development of 3D printers allowed a lot of limitations in the field of microfabrication to be circumvented. The ever-growing chase for smaller dimensions has come to an end in domains such as microfluidics, and the focus now shifted to a cost-efficiency challenge. In this paper, the use of a high-resolution stereolithography LCD 3D printer is investigated for fast and cheap production of microfluidic master molds. More precisely, the UV LED array and the LCD matrix of the printer act as an illuminator and a programmable photomask for soft lithography. The achieved resolution of around 100 μm is mainly limited by the pixel geometry of the LCD matrix. A tree-shape gradient mixer was fabricated using the presented method. It shows very good performances despite the presence of sidewall ripples due to the uneven pixel geometry of the LCD matrix. Any design can be brought from concept to realization in under 2 h. Given its sub-€1000 cost, this method is a very good entry point for labs wishing to explore the potential of microfluidic devices in their experiments, as well as a teaching tool for introducing students to microfluidics.

Similar content being viewed by others

Data availability

The data sets supporting the results of this article are included within the article and its additional files (cf Electronic Supplementary Material).

References

Convery N, Gadegaard N (2019) 30 years of microfluidics. Micro and Nano Engineering 2 (November 2018):76–91

Convery N, Gadegaard N (2019) 30 years of microfluidics. Micro and Nano Engineering 2:76–91

Whitesides GM (2006) The origins and the future of microfluidics. Nature 442(7101):368–373

Temiz Y, Lovchik RD, Kaigala GV, Delamarche E (2015) Lab-on-a-chip devices: how to close and plug the lab? Microelectron Eng 132:156–175

Pei H, Lu L, Han Z, Wang Y, Bo T (2020) Recent advances in microfluidic technologies for circulating tumor cells: enrichment, single-cell analysis, and liquid biopsy for clinical applications. Lab Chip 20 (21):3854–3875

Liu Y, Jiang X (2017) Why microfluidics? Merits and trends in chemical synthesis. Lab Chip 17(23):3960–3978

Nguyen HT, Ha T, Roy E, Huynh K, Perrault CMT (2018) Low-cost, accessible fabrication methods for microfluidics research in low-resource settings. Micromachines 9(9):1–10

Charmet J, Rodrigues R, Yildirim E, Challa PK, Roberts B, Dallmann R, Whulanza Y (2020) Low-cost microfabrication tool box. Micromachines 11(2):135

Lee JW, Daly SR, Huang-Saad AY, Seifert CM, Lutz J (2018) Using design strategies from microfluidic device patents to support idea generation. Microfluid Nanofluid 22(7):1–22

Gale BK, Jafek AR, Lambert CJ, Goenner BL, Moghimifam H, Nze UC, Kamarapu SK (2018) A review of current methods in microfluidic device fabrication and future commercialization prospects. Inventions 3(3):60

Khalkhal F, Chaney KH, Muller SJ (2016) Optimization and application of dry film photoresist for rapid fabrication of high-aspect-ratio microfluidic devices. Microfluid Nanofluid 20(11):153

Phrozen 3d lcd printers. https://www.phrozen3dp.com/categories/phrozen-lcd-3d-printer. Accessed 16 Feb 2021

Haubert K, Drier T, Beebe D (2006) Pdms bonding by means of a portable, low-cost corona system. Lab Chip 6(12):1548–1549

Martinus HV, Werts VR, Texier-Picard R, Poizat R, Franais O, Griscom L, Navarro JRG (2012) Quantitative full-colour transmitted light microscopy and dyes for concentration mapping and measurement of diffusion coefficients in microfluidic architectures. Lab Chip 12(4):808–820

Wang X, Liu Z, Pang Y (2017) Concentration gradient generation methods based on microfluidic systems. RSC Advances 7(48):29966–29984

Yi W, Mukherjee T, Lin Q (2006) Systematic modeling of microfluidic concentration gradient generators. J Micromech Microeng 16(10):2128–2137

Oh KW, Lee K, Ahn B, Furlani EP (2012) Design of pressure-driven microfluidic networks using electric circuit analogy. Lab Chip 12(3):515–545

Dertinger SKW, Chiu DT, Jeon NL, Whitesides GM (2001) Generation of gradients having complex shapes using microfluidic networks. Analytical Chemistry 73(6):1240–1246

Guckenberger DJ, De Groot TE, Wan AMD, Beebe DJ, Young EWK (2015) Micromilling: a method for ultra-rapid prototyping of plastic microfluidic devices. Lab Chip 15(11):2364–2378

Chung C, Chen YJ, Chen PC, Chen CY (2015) Fabrication of PDMS passive micromixer by lost-wax casting. Int J Precis Eng Manuf 16(9):2033–2039

Bazaz SR, Kashaninejad N, Azadi S, Patel K, Asadnia M, Jin D, Warkiani ME (2019) Rapid softlithography using 3D-printed molds. Advanced Materials Technologies 4(10):1–11

Renaudot R, Fouillet Y, Jalabert L, Kumemura M, Collard D, Fujita H, Agache V (2014) Programmable LDEP technology to fabricate versatile master molds for PDMS continuous-flow microfluidic applications. Microfluid Nanofluid 16(4):701– 710

Vulto P, Glade N, Altomare L, Bablet J, Del Tin L, Medoro G, Chartier I, Manaresi N, Tartagni M, Guerrieri R (2005) Microfluidic channel fabrication in dry film resist for production and prototyping of hybrid chips. Lab Chip 5(2):158

Maisonneuve BGC, Honegger T, Cordeiro J, Lecarme O, Thiry T, Fuard D, Berton K, Picard E, Zelsmann M, Peyrade D (2016) Rapid mask prototyping for microfluidics. Biomicrofluidics 10(2):024103

Deng T, Wu H, Brittain ST, Whitesides GM (2000) Prototyping of masks, masters, and stamps/molds for soft lithography using an office printer and photographic reduction. Anal Chem 72(14):3176–3180

Waheed S, Cabot JM, Macdonald NP, Lewis T, Guijt RM, Paull B, Breadmore MC (2016) 3D printed microfluidic devices: enablers and barriers. Lab Chip 16(11):1993–2013

Wang Z, Martin N, Hini D, Mills B, Kim K (2017) Rapid fabrication of multilayer microfluidic devices using the liquid crystal display-based stereolithography 3D printing system. 3D Printing and Additive Manufacturing 4(3):156–164

Kotz F, Risch P, Helmer D, Rapp BE (2019) High-performance materials for 3D printing in chemical synthesis applications. Advanced Materials 31(26):1805982

Au AK, Lee W, Folch A (2014) Mail-order microfluidics: evaluation of stereolithography for the production of microfluidic devices. Lab Chip 14(7):1294–1301

Kotz F, Arnold K, Wagner S, Bauer W, Keller N, Nargang TM, Helmer D, Rapp BE (2018) Liquid PMMA: a high resolution polymethylmethacrylate negative photoresist as enabling material for direct printing of microfluidic chips. Adv Eng Mater 20(2):1–5

Kiran Raj M, Chakraborty S (2020) PDMS Microfluidics: a mini review. J Appl Polym Sci 137(27):1–14

Mohamed MGA, Kumar H, Wang Z, Martin N, Mills B, Kim K (2019) Rapid and inexpensive fabrication of multi-depth microfluidic device using high-resolution LCD stereolithographic 3D printing. Journal of Manufacturing and Materials Processing 3(1):1–11

Frank P, Haefner S, Elstner M, Richter A (2016) 2016 fully-programmable, low-cost, “do-it-yourself” pressure source for general purpose use in the micro-uidic laboratory. Inventions 1(2):1–11

Thurgood P, Suarez SA, Chen S, Gilliam C, Pirogova E, Jex AR, Baratchi S, Khoshmanesh K (2019) Self-sufficient, low-cost microfluidic pumps utilising reinforced balloons. Lab Chip 19(17):2885–2896

Direct delivery of reagents from a pipette tip to a pdms microfluidic device. https://blogs.rsc.org/chipsandtips/2015/10/09/direct-delivery-of-reagents-from-a-pipette-tip-to-a-pdms-microfluidic-device/ . Accessed 14 October 2020

A simple microfluidic 4-way valve by clamping vinterconnected tubing. https://blogs.rsc.org/chipsandtips/2011/10/17/a-simple-microfluidic-4-way-valve-by-clamping-interconnected-tubing/. Accessed 14 October 2020

Funding

This research was funded by ANR under Project ANR-17-CE09-0009 SIPAIE (Aggregation Induced Emission at Single-Particle level).

Author information

Authors and Affiliations

Contributions

Conceptualization, M.L.; project administration, M.L, D.G.; methodology, all authors; data curation, V.C, T.T., software, M.L.; writing—original draft preparation, V.G. and M.L; writing—review and editing, all authors. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethics approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Consent to participate

The authors consent to participate.

Consent for publication

The authors consent to publish.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Colin, V.G., Travers, T., Gindre, D. et al. Cheap, versatile, and turnkey fabrication of microfluidic master molds using consumer-grade LCD stereolithography 3D printing. Int J Adv Manuf Technol 116, 537–544 (2021). https://doi.org/10.1007/s00170-021-07329-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07329-3