Abstract

Optimisation of machining parameters is crucial to ensure higher productivity and optimum outcomes in machining processes. By optimising machining parameters, a particular machining process can produce better machining outcomes within equivalent resources. This paper reviews past studies to achieve the desired outputs; minimum surface roughness (SR), highest material removal rate (MRR), lowest production cost, and the shortest production time of machining processes and various optimisation attempts in terms of varying parameters that affect the outcomes. The review deliberates the optimisation methods employed and analyses the performance discussing the relevant parameters that must have been considered by past researchers. To date, most studies have been focusing on optimising conventional machining processes such as turning, milling, and drilling. Optimisation works have been performed parametrically, experimentally, and numerically, where discrete variations of the parameters are investigated, while others are remained constant. Lately, evolutionary algorithm, statistical approaches such as genetic algorithm (GA), particle swarm optimisation (PSO), and cuckoo search algorithm (CSA) have been utilised in simultaneous optimisation of the parameters of the desired outputs and its great potential in optimising machining processes is recognisable.

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in this published article (and its supplementary information files).

References

Zolpakar NA, Lodhi SS, Pathak S, Sharma MA (2020) Application of multi-objective genetic algorithm (MOGA) optimization in machining processes. https://doi.org/10.1007/978-3-030-19638-7_8

Pathak S (2021) Intelligent manufacturing. https://doi.org/10.1007/978-3-030-50312-3

Abhishek K, Rakesh Kumar V, Datta S, Mahapatra SS (2017) Parametric appraisal and optimization in machining of CFRP composites by using TLBO (teaching–learning based optimization algorithm). J Intell Manuf 28:1769–1785

Pathak S, Jain NK (2017) Critical review of electrochemical honing: sustainable and alternative gear finishing process. Part 2: effects of various process parameters on surface characteristics and material removal rate. Trans Inst Met Finish 95:241–254

Pathak S, Jain NK (2017) Critical review of electrochemical honing (ECH): sustainable and alternative gear finishing process. Part 1: conventional processes and introduction to ECH. Trans Inst Met Finish 95:147–157

Shaikh JH, Jain NK, Pathak S (2016) Investigations on surface quality improvement of straight bevel gears by electrochemical honing process. Proc Inst Mech Eng Part B J Eng Manuf 230:1242–1253

Gupta MK, Sood PK, Sharma VS (2016) Optimization of machining parameters and cutting fluids during nano-fluid based minimum quantity lubrication turning of titanium alloy by using evolutionary techniques. J Clean Prod 135:1276–1288

Zain AM, Haron H, Sharif S (2010) Application of GA to optimize cutting conditions for minimizing surface roughness in end milling machining process. Expert Syst Appl 37:4650–4659

Zainal N, Zain AM, Radzi NHM, Othman MR (2016) Glowworm swarm optimization (GSO) for optimization of machining parameters. J Intell Manuf 27:797–804

Mia M, Dey PR, Hossain MS, Arafat MT, Asaduzzaman M, Shoriat Ullah M, Tareq Zobaer SM (2018) Taguchi S/N based optimization of machining parameters for surface roughness, tool wear and material removal rate in hard turning under MQL cutting condition. Meas J Int Meas Confed 122:380–391

Sangwan KS, Kant G (2017) Optimization of machining parameters for improving energy efficiency using integrated response surface methodology and genetic algorithm approach. Procedia CIRP 61:517–522

Pawanr S, Garg GK, Routroy S (2020) Multi-objective optimization of machining parameters to minimize surface roughness and power consumption using TOPSIS. Procedia CIRP 86:116–120

Kuntoğlu M, Sağlam H (2019) Investigation of progressive tool wear for determining of optimized machining parameters in turning. Meas J Int Meas Confed 140:427–436

Krishnaraj V, Prabukarthi A, Ramanathan A, Elanghovan N, Kumar MS, Zitoune R, Davim JP (2012) Optimization of machining parameters at high speed drilling of carbon fiber reinforced plastic (CFRP) laminates. Compos Part B Eng 43:1791–1799

Kant G, Sangwan KS (2014) Prediction and optimization of machining parameters for minimizing power consumption and surface roughness in machining. J Clean Prod 83:151–164

Rajmohan T, Palanikumar K, Kathirvel M (2012) Optimization of machining parameters in drilling hybrid aluminium metal matrix composites. Trans Nonferrous Metals Soc China English Ed 22:1286–1297

Wang Q, Liu F, Wang X (2014) Multi-objective optimization of machining parameters considering energy consumption. Int J Adv Manuf Technol 71:1133–1142

Maiyar LM, Ramanujam R, Venkatesan K, Jerald J (2013) Optimization of machining parameters for end milling of Inconel 718 super alloy using Taguchi based grey relational analysis. Procedia Eng 64:1276–1282

Sangwan KS, Saxena S, Kant G (2015) Optimization of machining parameters to minimize surface roughness using integrated ANN-GA approach. Procedia CIRP 29:305–310

Yildiz AR (2013) Cuckoo search algorithm for the selection of optimal machining parameters in milling operations. Int J Adv Manuf Technol 64:55–61

Lodhi BK, Agarwal S (2014) Optimization of machining parameters in WEDM of AISI D3 steel using taguchi technique. Procedia CIRP 14:194–199

Aliakbari E, Baseri H (2012) Optimization of machining parameters in rotary EDM process by using the Taguchi method. Int J Adv Manuf Technol 62:1041–1053

Rajmohan T, Palanikumar K (2013) Application of the central composite design in optimization of machining parameters in drilling hybrid metal matrix composites. Meas J Int Meas Confed 46:1470–1481

Zhou G, Lu Q, Xiao Z, Zhou C, Tian C (2019) Cutting parameter optimization for machining operations considering carbon emissions. J Clean Prod 208:937–950

Sathish T (2019) Experimental investigation of machined hole and optimization of machining parameters using electrochemical machining. J Mater Res Technol 8:4354–4363

Mirkoohi E, Bocchini P, Liang SY (2019) Analytical temperature predictive modeling and non-linear optimization in machining. Int J Adv Manuf Technol 102:1557–1566

Wang G, Li W, Rao F, He Z, Yin Z (2019) Multi-parameter optimization of machining impeller surface based on the on-machine measuring technique. Chin J Aeronaut 32:2000–2008

Camposeco-Negrete C (2019) Prediction and optimization of machining time and surface roughness of AISI O1 tool steel in wire-cut EDM using robust design and desirability approach. Int J Adv Manuf Technol 103:2411–2422

Azlan Suhaimi M, Park KH, Sharif S, Kim DW, Saladin Mohruni A (2017) Evaluation of cutting force and surface roughness in high-speed milling of compacted graphite iron. MATEC Web Conf 101. https://doi.org/10.1051/matecconf/201710103016

Rajmohan T (2019) Experimental investigation and optimization of machining parameters in drilling of fly ash-filled carbon fiber reinforced composites. Part Sci Technol 37:21–30

Vijayabhaskar S, Rajmohan T (2019) Experimental investigation and optimization of machining parameters in WEDM of nano-SiC particles reinforced magnesium matrix composites. Silicon 11:1701–1716

Mahesh G, Muthu S, Devadasan SR (2015) Prediction of surface roughness of end milling operation using genetic algorithm. Int J Adv Manuf Technol 77:369–381

Khare SK, Phull GS, Verma RK, Agarwal S (2020) A comparison between optimization techniques of cutting parameters under cryogenic machining process. Mater Today Proc 26:2697–2700. https://doi.org/10.1016/j.matpr.2020.02.567

Maneiah D, Shunmugasundaram M, Raji Reddy A, Begum Z (2020) Optimization of machining parameters for surface roughness during abrasive water jet machining of aluminium/magnesium hybrid metal matrix composites. Mater Today Proc 27:1293–1298. https://doi.org/10.1016/j.matpr.2020.02.264

Karthik Pandiyan G, Prabaharan T (2020) Optimization of machining parameters on AA6351 alloy steel using Response Surface Methodology (RSM). Mater Today Proc:1–4

Zubair AF, Abu Mansor MS (2019) Embedding firefly algorithm in optimization of CAPP turning machining parameters for cutting tool selections. Comput Ind Eng 135:317–325

Fazlollahtabar H, Gholizadeh H (2020) Fuzzy possibility regression integrated with fuzzy adaptive neural network for predicting and optimizing electrical discharge machining parameters. Comput Ind Eng 140:106225

Chethan YD, Ravindra HV, Krishnegowda YT (2019) Optimization of machining parameters in turning Nimonic-75 using machine vision and acoustic emission signals by Taguchi technique. Meas J Int Meas Confed 144:144–154

Leo Kumar SP (2018) Experimental investigations and empirical modeling for optimization of surface roughness and machining time parameters in micro end milling using Genetic Algorithm. Meas J Int Meas Confed 124:386–394

Sathiya Narayanan N, Baskar N, Ganesan M (2018) Multi objective optimization of machining parameters for hard turning OHNS/AISI H13 material, using genetic algorithm. Mater Today Proc 5:6897–6905

Dhavamani C, Alwarsamy T (2012) Optimization of machining parameters for aluminum and silicon carbide composite using genetic algorithm. Procedia Eng 38:1994–2004

Reddy VC, Gowd GH, Kumar MLSD (2018) Empirical modeling & optimization of laser micro - machining process parameters using genetic algorithm. Mater Today Proc 5:8095–8103

Fountas NA, Vaxevanidis NM (2020) Intelligent 3D tool path planning for optimized 3-axis sculptured surface CNC machining through digitized data evaluation and swarm-based evolutionary algorithms. Meas J Int Meas Confed 158:107678

Manav O, Chinchanikar S (2018) Multi-objective optimization of hard turning: a genetic algorithm approach. Mater Today Proc 5:12240–12248

Selvam MD, Karuppusami G, Dawood AKS (2012) Optimization of machining parameters for face milling operation in a vertical cnc milling machine using genetic algorithm. An Int J ESTIJ 2:2250–3498

Zhang W, Zhang L, Wang S, Ren B, Meng S (2019) Optimization of machining parameters of 2.25Cr1Mo0.25V steel based on response surface method and genetic algorithm. Int J Interact Des Manuf 13:809–819

Umer U, Mohammed MK, Al-Ahmari A (2017) Multi-response optimization of machining parameters in micro milling of alumina ceramics using Nd:YAG laser. Meas J Int Meas Confed 95:181–192

Gupta I, Tyagi G (2017) Optimization of machining parameters in electrical discharge machining process of Ti-6Al-4V alloy by Taguchi method. 3:44–50

Nain SS, Garg D, Kumar S (2018) Investigation for obtaining the optimal solution for improving the performance of WEDM of super alloy Udimet-L605 using particle swarm optimization. Eng Sci Technol an Int J 21:261–273

Manav O, Chinchanikar S, Gadge M (2018) Multi-performance optimization in hard turning of AISI 4340 steel using particle swarm optimization technique. Mater Today Proc 5:24652–24663

Sridhar R, Perumal Subramaniyan S, Ramesh S (2019) Optimization of machining and geometrical parameters to reduce vibration while milling metal matrix composite. Trans Indian Inst Metals 72:3179–3189

Gopalakrishnan R, John ERD (2017) Experimental investigation and multi response optimization of WEDM process of AA7075 metal matrix composites using particle swarm optimization. Int J Intell Eng Syst 10:166–174

Marko H, Simon K, Tomaz I, Matej P, Joze B, Miran B (2014) Turning parameters optimization using particle swarm optimization. Procedia Eng 69:670–677

Sreenivasa Rao M, Venkaiah N (2015) Parametric optimization in machining of nimonic-263 alloy using RSM and particle swarm optimization. Procedia Mater Sci 10:70–79

Malghan RL, Rao KMC, Shettigar AK, Rao SS, D’Souza RJ (2017) Application of particle swarm optimization and response surface methodology for machining parameters optimization of aluminium matrix composites in milling operation. J Braz Soc Mech Sci Eng 39:3541–3553

Jabri A, El Barkany A, El Khalfi A (2017) Multipass turning operation process optimization using hybrid genetic simulated annealing algorithm. Model Simul Eng 2017:1–10. https://doi.org/10.1155/2017/1940635

Varatharajulu M, Loganathan C, Baskar N (2015) Influence of cutting parameters on roughness and roundness in drilling of duplex 2205 using high speed steel. Int J Appl Eng Res 10:129–136

Sathish T (2018) BCCS approach for the parametric optimization in machining of nimonic-263 alloy using RSM. Mater Today Proc 5:14416–14422

Mohamad A, Zain AM, Mohd Yusof N, Najarian F, Alwee R, Abdull Hamed HN (2019) Modeling and optimization of machining parameters using regression and cuckoo search in deep hole drilling process. Appl Mech Mater 892:177–184

Huang J, Gao L, Li X (2015) An effective teaching-learning-based cuckoo search algorithm for parameter optimization problems in structure designing and machining processes. Appl Soft Comput J 36:349–356

Saravanan M, Thiyagarajan C, Somasundaram S (2020) Parametric optimization of wirecut-electrical discharge machining through cuckoo search algorithm. Mater Today Proc 22:681–687

Priti SM, Singh S (2020) Materials today : proceedings micro-machining of CFRP composite using electrochemical discharge machining and process optimization by Entropy-VIKOR method. Mater Today Proc 44:260–265. https://doi.org/10.1016/j.matpr.2020.09.463

Singh T, Rathore RS, Dvivedi A (2020) Experimental investigations, empirical modeling and multi objective optimization of performance characteristics for ECDD with pressurized feeding method. Measurement 149:107017

Reddy BS, Rao ABK, Janardhana GR (2020) Multi-objective optimization of surface roughness, recast layer thickness and surface crack density in WEDM of Al2124/SiCp using desirability approach. Mater Today Proc 39:1320–1326. https://doi.org/10.1016/j.matpr.2020.04.563

Thakur RK, Singh KK (2020) Experimental investigation and optimization of abrasive water jet machining parameter on multi-walled carbon nanotube doped epoxy/carbon laminate. Measurement 2020:108093

Balaji K, Kumar MS, Yuvaraj N (2021) Multi objective taguchi – grey relational analysis and krill herd algorithm approaches to investigate the parametric optimization in abrasive water jet drilling of stainless steel. Appl Soft Comput J 102:107075

Kumar KR, Sreebalaji VS, Pridhar T (2017) Characterization and optimization of abrasive water jet machining parameters of aluminium /tungsten carbide composites. Measurement. 117:57–66. https://doi.org/10.1016/j.measurement.2017.11.059

Shukla R, Singh D (2016) Author’s Accepted Manuscript. Swarm Evol Comput 32:167–183. https://doi.org/10.1016/j.swevo.2016.07.002

Gostimirovic M, Pucovsky V, Sekulic M, Rodic D, Pejic V (2018) Evolutionary optimization of jet lag in the abrasive water jet machining.

Acharya BR, Mohanty CP, Mahapatra SS (2013) Multi-objective optimization of electrochemical machining of hardened steel using NSGA II. Procedia Eng 51:554–560

Sohrabpoor H, Khanghah SP, Shahraki S, Teimouri R (2016) Multi-objective optimization of electrochemical machining process, pp 1683–1692

Santhi M (2013) Optimization of process parameters in electro chemical machining ( ECM ) using DFA-fuzzy set theory-TOPSIS for titanium alloy. Multidiscip Model Mater Struct 9:243–255

Mehrvar A, Basti A, Jamali A (2016) Optimization of electrochemical machining process parameters : combining response surface methodology and differential evolution algorithm. J Process Mech Eng 1:1–13

Mariapushpam T, Jegan C (2017) Electrochemical machining process parameter optimization using particle swarm optimization. Comput Intell:1–19

Sathiyamoorthy V, Sekar T, Elango N (2015) Optimization of processing parameters in ECM of die tool steel using nanofluid by multiobjective genetic algorithm. Sci World J 2015:1–7

Holland JH (1957) Adaptation in natural An introductory analysis with applications to biology, 3 pages

Deb K (2001) Multi-objective optimization using evolutionary algorithms: an introduction multi-objective optimization using evolutionary algorithms: an introduction. Wiley-Interscience Ser Syst Optim, pp 1–24

Alberto I, Azcarate C, Mallor F, Mateo PM (2003) Multiobjective evolutionary algorithms. Pareto Rankings. Proc VII Jornadas Zaragoza-Pau Matemática Apl y Estadística Monogr del Semin Mat Garcia Galdeano no27 27:27–35

Eberhart JKCR (2AD) Particle swarm optimization. Adapt Learn Optim 15:45–82

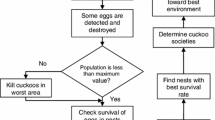

Yang XS, Deb S (2009) Cuckoo search via Lévy flights. 2009 World Congr Nat Biol Inspired Comput NABIC 2009 - Proc 210–214

Joshi AS, Kulkarni O, Kakandikar GM, Nandedkar VM (2017) Cuckoo Search Optimization—a review. Mater Today Proc 4:7262–7269

Khoja I, Ladhari T, Sakly A, M’Sahli F (2018) Parameter identification of an activated sludge wastewater treatment process based on particle swarm optimization method. Math Probl Eng 2018:1–11. https://doi.org/10.1155/2018/7823930

Piotrowski AP, Napiorkowski JJ, Piotrowska AE (2020) Population size in particle swarm optimization. Swarm Evol Comput 58:100718

Ding J, Wang Q, Zhang Q, Ye Q, Ma Y (2019) A hybrid particle swarm optimization-Cuckoo Search Algorithm and its engineering applications. Math Probl Eng 2019:1–12. https://doi.org/10.1155/2019/5213759

Funding

The research works are done using the facilities at Universiti Malaysia Pahang for Research University Grant (RDU1803144) and Ministry of Higher Education for Fundamental Research Grant Scheme (FRGS) (FRGS/1/2019/TK10/UMP/03/2) (RDU1901193), through the course of this research.

Author information

Authors and Affiliations

Contributions

Nor Atiqah Zolpakar: writing – original draft, analysis of technical papers. Mohd Fuad Yasak: Conceptualization, writing – review and editing. Sunil Pathak: Critical review on advanced machining, writing – review and editing.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zolpakar, N.A., Yasak, M.F. & Pathak, S. A review: use of evolutionary algorithm for optimisation of machining parameters. Int J Adv Manuf Technol 115, 31–47 (2021). https://doi.org/10.1007/s00170-021-07155-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07155-7