Abstract

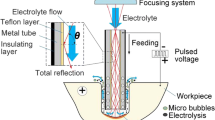

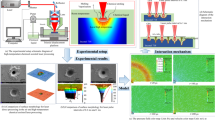

With the rapid development of the information age, electronic components are developing toward miniaturization, which makes the manufacturing of chips more and more difficult. Water jet-guided laser processing technology (WJGL) is a composite processing technology that combines pulsed laser and water jet, which can ensure the accuracy and efficiency of processing while small size parts machining. This paper is based on the “element birth and death” technique in the finite element method and the three-dimensional transient temperature field and subsequent material removal model of 6061 aluminum alloy are established. The effects of laser average power, pulse repetition frequency, and pulse action time on the transient thermal distribution, aperture, taper, and other forming qualities with the two technologies of fixed-point drilling and spiral drilling, respectively, are studied. Combining the experimental process, the general rule of morphology change of the micro-hole is obtained. The results show that WJGL of micro-hole is based on the combined effect of thermal ablation and real-time cooling. Spiral drilling can maintain a better hole shape but fixed-point drilling can achieve a smaller hole taper. With the increase of laser power, the hole taper increases, reaching saturation at 8 W. The repetition frequency is between 50 and 70 kHz to obtain better hole morphology while maintaining better processing efficiency, and the minimum hole taper is 8.21°.

Similar content being viewed by others

References

Tian LP (2006) Integrated circuit key equipment market analysis and development strategy. Equip Electron Prod Manuf 01:4–10

Yang W, Xiang D, Du F, Wang W, Tian H (2015) Study on the influence factors of key structure and main process parameters of wet etching machine chamber on etching performance. J Synth Cryst 04:209–215

Suman C, Sankar MS, Arpan M, Kumar A (2018) An experimental study on drilling of titanium alloy using CO2 laser. Sādhanā 43(8):1–14

Zhu FS, Xia NJ, Zhao BJ, Huang XL, Wang WL (2019) Study on improving etching uniformity of silicon by wet etching. Equip Electron Prod Manuf 48(05):13–16

Suman C, Sankar MS, Bharadwaj V, Choubey A, Bindra KS (2018) Drilling of micro-holes on titanium alloy using pulsed Nd:YAG laser: parametric appraisal and prediction of performance characteristics. Proc Inst Mech Eng B J Eng Manuf 233(1):1–18

Kikin PY, Pchelintsev AI, Rusin EE (2007) Features of the hole shape formation during laser drilling of an ultrafine-grained aluminum alloy. Tech Phys Lett 33(11):917–918

Kikin PY, Perevezentsev VN, Pchelintsev AI, Rusin EE (2006) Effect of ultrafine-grained structure on the regime of laser drilling in aluminum alloy 1420. Tech Phys Lett 32(10):845–846

Ren NF, Xia KB, Wang HX (2015) Investigation on microhole formation characteristics for pulsed laser drilling of aluminum alloy 5052 sheets. Laser Optoelectron Progress 52(12):117–121

Zang YN, Ni XW, Chen YB (2013) Simulation of long pulsed laser drilling on metal based on birth and death method of ANSYS. Chin J Lasers 40(6):177–182

Li MX, Jin GY, Guo M, Wang D, Gu XY (2014) Theoretical simulation of melt ejection during the laser drilling process on aluminum alloy by single pulsed laser. SPIE 9295

Sanjay M, Vinod Y (2013) Modeling and optimization of laser beam percussion drilling of thin aluminum sheet. Opt Laser Technol 48:461–474

Sanjay M, Vinod Y (2013) Prediction of hole characteristics and hole productivity during pulsed Nd:YAG laser beam percussion drilling. Proc Inst Mech Eng B J Eng Manuf 227(B4):494–507

Fujita M, Ohkawa H, Somekawa T, Otsuka M, Maeda Y, Matsutani T, Miyanaga N (2016) Wavelength and pulse width dependences of laser processing of CFRP. Phys Procedia 83:1031–1036

Liu YS, Wang C, Li W, Zhang L, Yang X, Cheng G, Zhang Q (2014) Effect of energy density and feeding speed on micro-hole drilling in C/SiC composites by picosecond laser. J Mater Process Technol 214(12):3131–3140

Kalyanasundaram D, Shehata G, Neumann C, Shrotriya P, Molian P (2008) Design and validation of a hybrid laser/water-jet machining system for brittle materials. J Laser Appl 20(2):127

Feng S, Huang C, Wang J, Zhu H (2017) Investigation and modelling of hybrid laser-waterjet micromachining of single crystal SiC wafers using response surface methodology. Mater Sci Semicond Process 68:199–212

Yang CM, Jiang T, Yu Y, Dun G, Ma Y, Liu J (2018) Study on surface quality of wood processed by water-jet assisted nanosecond laser. Bioresources 13(2):3125–3134

Zhang YN, Qiao HC, Zhao JB, Cao ZH, Yu YF (2020) Numerical simulation of water jet–guided laser micromachining of CFRP. Mater Today Commun 25:1–10

Shi Y, Jiang Z, Cao J, Ehmann KF (2019) Texturing of metallic surfaces for superhydrophobicity by water jet guided laser micro-machining. Appl Surf Sci 500:144286

Kilickap E (2010) Optimization of cutting parameters on delamination based on Taguchi method during drilling of GFRP composite. Expert Syst Appl 37(8):6116–6122

Suman C, Siba SM, Vijay B, Brahma NU, Khushvinder SB (2019) Prediction of quality characteristics of laser drilled holes using artificial intelligence techniques. Eng Comput 37:1181–1204

Zheng F (2008) Aluminum and aluminum alloy quick check manual. Chemical Industry Press

Li JM, Lu CH, Zhang JQ (2016) Computational and experimental investigations of laser marking on 6061 aluminum alloy. Lasers Eng 33:1–3

Li CF, Johnson DB, Kovacevic R (2003) Modeling of water jet guided laser grooving of silicon. Int J Mach Tool Manu 43(9):925–936

Acknowledgements

This study was supported by the National Natural Science Foundation of China (51875558).

Availability of data and materials

Not applicable.

Funding

This study was supported by the National Natural Science Foundation of China (51875558).

Author information

Authors and Affiliations

Contributions

Yinuo Zhang contributed to the conception of the study.

Hongchao Qiao performed the experiment.

Jibin Zhao contributed significantly to analysis and manuscript preparation.

Zhihe Cao helped perform the analysis with constructive discussions.

Corresponding authors

Ethics declarations

Ethical approval

We can prove that this work belongs to field of laser processing of aerooengines, and this work did not involve the human ethical issues. And we promise that we can follow the COPE guidelines on how to deal with potential acts of misconduct. So we hope this work can be consideration of the publication by “The International Journal of Advanced Manufacturing Technology”.

Consent to participate

All the authors consent to participate this work.

Consent to publish

All the authors in this work have consented to publish this manuscript.

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Qiao, H., Zhao, J. et al. Research on water jet-guided laser micro-hole machining of 6061 aluminum alloy. Int J Adv Manuf Technol 118, 1–13 (2022). https://doi.org/10.1007/s00170-021-07104-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07104-4