Abstract

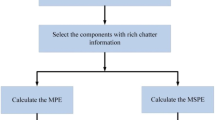

Chatter monitoring is an important task while ensuring machining quality and improving machining efficiency. Under variable cutting conditions, cutting parameters often change, and the cutting state and traditional time-frequency domain cutting features will also change significantly. In order to achieve precise monitoring of chatter under such cutting conditions, this article proposes a time series method named recurrence plot (RP) that can reflect the non-stationary characteristics and state differences of the signal system to analyze the cutting force signal in the cutting process. Firstly, reconstruct the phase space, generate RP; then use recurrence quantitative analysis (RQA) to extract statistical features in the RP that reflect the current state of the system; thirdly, use affinity propagation (AP) clustering method to find out the exemplar features from the RQA; finally, train the exemplar features using the light gradient boosting (LGB) method to obtain the classification prediction model. Experimental results show that this method can effectively identify the machining chatter state and stable cutting state under variable cutting conditions.

Similar content being viewed by others

Data availability

Not applicable

References

Quintana G, Ciurana J (2011) Chatter in machining processes: a review. Int J Mach Tools Manuf 51(5):363–376. https://doi.org/10.1016/j.ijmachtools.2011.01.001

Cao H, Zhang X, Chen X (2017) The concept and progress of intelligent spindles: a review. Int J Mach Tools Manuf 112:21–52. https://doi.org/10.1016/j.ijmachtools.2016.10.005

Zhu L, Liu C (2020) Recent progress of chatter prediction, detection and suppression in milling. Mech Syst Signal Process 143:106840. https://doi.org/10.1016/j.ymssp.2020.106840

Chen GS, Zheng QZ (2017) Online chatter detection of the end milling based on wavelet packet transform and support vector machine recursive feature elimination. Int J Adv Manuf Technol 95(1-4):775–784. https://doi.org/10.1007/s00170-017-1242-9

Ye J, Feng P, Xu C, Ma Y, Huang S (2018) A novel approach for chatter online monitoring using coefficient of variation in machining process. Int J Adv Manuf Technol 96(1-4):287–297. https://doi.org/10.1007/s00170-017-1544-y

Vela-Martínez L, Jáuregui-Correa JC, Álvarez-Ramírez J (2009) Characterization of machining chattering dynamics: an R/S scaling analysis approach. Int J Mach Tools Manuf 49(11):832–842. https://doi.org/10.1016/j.ijmachtools.2009.05.010

Cao H, Lei Y, He Z (2013) Chatter identification in end milling process using wavelet packets and Hilbert–Huang transform. Int J Mach Tools Manuf 69:11–19. https://doi.org/10.1016/j.ijmachtools.2013.02.007

Wang G, Dong H, Guo Y, Ke Y (2017) Early chatter identification of robotic boring process using measured force of dynamometer. Int J Adv Manuf Technol 94(1-4):1243–1252. https://doi.org/10.1007/s00170-017-0941-6

Moradi H, Movahhedy MR, Vossoughi G (2012) Dynamics of regenerative chatter and internal resonance in milling process with structural and cutting force nonlinearities. J Sound Vib 331(16):3844–3865. https://doi.org/10.1016/j.jsv.2012.03.003

Liu Y, Wang X, Lin J, Zhao W (2015) Early chatter detection in gear grinding process using servo feed motor current. Int J Adv Manuf Technol 83(9-12):1801–1810. https://doi.org/10.1007/s00170-015-7687-9

Liu H, Chen Q, Li B, Mao X, Mao K, Peng F (2011) On-line chatter detection using servo motor current signal in turning. Sci China Technol Sci 54(12):3119–3129. https://doi.org/10.1007/s11431-011-4595-6

Caliskan H, Kilic ZM, Altintas Y (2018) On-line energy-based milling chatter detection. J Manuf Sci Eng 140(11). https://doi.org/10.1115/1.4040617

Vashisht RK, Peng Q (2021) Online chatter detection for milling operations using LSTM neural networks assisted by motor current signals of ball screw drives. J Manuf Sci Eng 143(1). https://doi.org/10.1115/1.4048001

Schmitz TL (2003) Chatter recognition by a statistical evaluation of the synchronously sampled audio signal. J Sound Vib 262(3):721–730. https://doi.org/10.1016/s0022-460x(03)00119-6

Chiou RY, Liang SY (2000) Analysis of acoustic emission in chatter vibration with tool wear effect in turning. Int J Mach Tool Manu 40(7):927–941

Wang X, Song Q, Liu Z (2020) Precise chatter monitoring of thin-walled component milling process based on parametric time-frequency transform method. J Mater Process Technol 283:283. https://doi.org/10.1016/j.jmatprotec.2020.116712

Kuljanic E, Sortino M, Totis G (2008) Multisensor approaches for chatter detection in milling. J Sound Vib 312(4-5):672–693. https://doi.org/10.1016/j.jsv.2007.11.006

Huang NE, Shen Z, Long SR, Wu MC, Shih HH, Zheng Q, Yen N-C, Tung CC, Liu HH (1998) The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc R Soc Lond Ser A Math Phys Eng Sci 454(1971):903–995

Huang NE, Wu Z (2008) A review on Hilbert-Huang transform: method and its applications to geophysical studies. Rev Geophys 46(2). https://doi.org/10.1029/2007rg000228

Yang Z, Yu Z, Xie C, Huang Y (2014) Application of Hilbert–Huang transform to acoustic emission signal for burn feature extraction in surface grinding process. Measurement 47:14–21. https://doi.org/10.1016/j.measurement.2013.08.036

Litak G, Kecik K, Rusinek R (2013) Cutting force response in milling of inconel: analysis by wavelet and Hilbert-Huang transforms. Latin Am J Solids Struct 10(1):133–140

Wolszczak P, Litak G, Łygas K (2017) Monitoring of cutting conditions with the empirical mode decomposition. Adv Sci Technol Res J 11(1):96–103. https://doi.org/10.12913/22998624/68467

Peng ZK, Tse PW, Chu FL (2005) A comparison study of improved Hilbert–Huang transform and wavelet transform: application to fault diagnosis for rolling bearing. Mech Syst Signal Process 19(5):974–988. https://doi.org/10.1016/j.ymssp.2004.01.006

Rafal R, Pawel L, Krzysztof K, Bogdan K, Jerzy W (2015) Chatter identification methods on the basis of time series measured during titanium superalloy milling. Int J Mech Sci 99:196–207. https://doi.org/10.1016/j.ijmecsci.2015.05.013

Trulla LL, Giuliani A, Zbilut JP, Webber CL (1996) Recurrence quantification analysis of the logistic equation with transients. Phys Lett A 223(4):255–260

Eckmann JP, Kamphorst SO, Ruelle D (1987) Recurrence plots of dynamical systems. Europhys Lett (EPL) 4(9):973–977. https://doi.org/10.1209/0295-5075/4/9/004

Webber CL Jr, Zbilut JP (1994) Dynamical assessment of physiological systems and states using recurrence plot strategies. J Appl Physiol (1985) 76(2):965–973. https://doi.org/10.1152/jappl.1994.76.2.965

Lydic R (1987) State-dependent aspects of regulatory physiology. FASEB J 1(1):6–15. https://doi.org/10.1096/fasebj.1.1.3301498

Thaler T, Krese B, Govekar E (2015) Stability diagrams and chatter avoidance in horizontal band sawing. CIRP Ann 64(1):81–84. https://doi.org/10.1016/j.cirp.2015.04.081

Rusinek R, Lajmert P (2020) Chatter detection in milling of carbon fiber-reinforced composites by improved Hilbert-Huang transform and recurrence quantification analysis. Materials (Basel) 13(18). https://doi.org/10.3390/ma13184105

Fu Y, Zhang Y, Zhou H, Li D, Liu H, Qiao H, Wang X (2016) Timely online chatter detection in end milling process. Mech Syst Signal Process 75:668–688. https://doi.org/10.1016/j.ymssp.2016.01.003

Yao Z, Mei D, Chen Z (2010) On-line chatter detection and identification based on wavelet and support vector machine. J Mater Process Technol 210(5):713–719. https://doi.org/10.1016/j.jmatprotec.2009.11.007

Li K, He S, Li B, Liu H, Mao X, Shi C (2020) A novel online chatter detection method in milling process based on multiscale entropy and gradient tree boosting. Mech Syst Signal Process 135:135. https://doi.org/10.1016/j.ymssp.2019.106385

Frey BJ, Dueck D (2007) Clustering by passing messages between data points. Science 315(5814):972–976

Ke G, Meng Q, Finley T, Wang T, Chen W, Ma W, Ye Q, Liu T-Y (2017) Lightgbm: a highly efficient gradient boosting decision tree. In: Advances in neural information processing systems, pp 3146-3154

Cao L (1997) Practical method for determining the minimum embedding dimension of a scalar time series. Physica D: Nonlinear Phenomena 110(1-2):43–50

Spiegel S, Marwan N (2016) Time and again. In: Machine Learning and Knowledge Discovery in Databases. Lecture Notes in Computer Science. pp 258-262. https://doi.org/10.1007/978-3-319-46131-1_30

Hou Y, Aldrich C, Lepkova K, Machuca LL, Kinsella B (2017) Analysis of electrochemical noise data by use of recurrence quantification analysis and machine learning methods. Electrochim Acta 256:337–347. https://doi.org/10.1016/j.electacta.2017.09.169

Voss HU, Kurths J (1997) Reconstruction of nonlinear time delay models from data by the use of optimal transformations. Phys Lett A 234(5):336–344

Eckmann JP, Ruelle D (1985) Ergodic theory of chaos and strange attractors. Rev Mod Phys 57(3):617–656. https://doi.org/10.1103/RevModPhys.57.617

Marwan N, Carmenromano M, Thiel M, Kurths J (2007) Recurrence plots for the analysis of complex systems. Phys Rep 438(5-6):237–329. https://doi.org/10.1016/j.physrep.2006.11.001

Marwan N, Donges JF, Zou Y, Donner RV, Kurths J (2009) Complex network approach for recurrence analysis of time series. Phys Lett A 373(46):4246–4254. https://doi.org/10.1016/j.physleta.2009.09.042

Altintas Y (2012) Manufacturing automation : metal cutting mechanics, machine tool vibrations, and CNC design, 2nd edn. Cambridge University Press

Shao Q, Feng CJ (2011) Pattern recognition of chatter gestation based on hybrid PCA-SVM. Appl Mech Mater 120:190–194. https://doi.org/10.4028/www.scientific.net/AMM.120.190

Cao H, Zhou K, Chen X, Zhang X (2017) Early chatter detection in end milling based on multi-feature fusion and 3σ criterion. Int J Adv Manuf Technol 92(1–4):4387–4397

Materials availability

Not applicable

Code availability

Not applicable

Funding

This work was financially supported by the National Natural Science Foundation (No. 51905410), the China Postdoctoral Science Foundation (No. BX20180253, 219945), the Fundamental Research Funds for the Central Universities (No. xzy012019009, xxj022019025), and the Major Science and Technology Project of Shaanxi Province (No. 2019zdzx01-01-02).

Author information

Authors and Affiliations

Contributions

Kunhong Chen: methodology, formal analysis, writing—original draft.

Xing Zhang: conceptualization, writing—review and editing.

Zhao Zhao: data selection

Jia Yin: conceptualization.

Wanhua Zhao: conceptualization.

Corresponding author

Ethics declarations

Ethical approval

Not applicable

Consent to participate

Not applicable

Consent to publish

Not applicable

Competing interests

The authors declare no competing interests

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, K., Zhang, X., Zhao, Z. et al. Milling chatter monitoring under variable cutting conditions based on time series features. Int J Adv Manuf Technol 113, 2595–2613 (2021). https://doi.org/10.1007/s00170-021-06746-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06746-8