Abstract

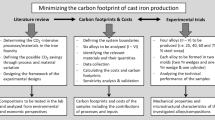

Machine tool is the core of manufacturing, and one of its indispensable parts is the machine tool bed, which is mainly composed of cast iron and exhibits high material consumption. Owing to the high carbon emissions of steel industries and the limitation of steel reserves, resin mineral composite machine tool beds have been developed. But the carbon emissions of the resin mineral composite machine tool bed are not assessed. A life cycle assessment (LCA) was conducted to investigate the carbon emissions across the life cycle phases of cast iron machine tool bed and resin mineral composite machine tool bed. The uses of cast iron and resin mineral composite for machine tool bed were compared. LCA was employed to establish a carbon emission assessment model for the raw material acquisition phase, manufacturing phase, recycling phase, and disposal phase. Carbon emission assessments were conducted based on reliable survey data. The cast iron machine tool bed has a total carbon emission of 5673.60 kgCO2eq, and the resin mineral composite bed has a total carbon emission of 1259.37 kgCO2eq. Compared with the cast iron machine tool bed, the resin mineral composite machine tool bed reduces carbon emissions by 77.80%. It was found that the carbon emission of the cast iron machine tool bed was greater than that of the resin mineral composite tool bed. It lays a foundation for the research on the potentiality of the resin mineral composite machine tool bed to replace the cast iron machine tool bed form the point of environmental aspects.

Similar content being viewed by others

Data availability

The authors thank Chongqing Machine Tool (Group) Co., Ltd help to provide data support. The datasets used or analysed during this manuscript are available from the corresponding author on reasonable request.

References

China’s carbon emissions trading network, http://www.tanjiaoyi.com/article-2927-1.html

Sun GQ (2016) Discussion on energy saving and emission reduction measures in foundry industry. Energy Res Utiliz 2

Wang XW, Zhang XL, Zhang DJ, Wang L (2018) Research progress on carbon emission calculation model of cutting machining of generalized machine tools. J Shandong Dong Jianzhu Univ 33(5):79–83

Cao HJ, Li HC, Song SL, Du YB, Chen P (2011) Evaluation method and application for carbon emissions of machine tool based on life cycle assessment. Comput Integr Manuf Syst 17(11):2432–2437

Shahed S (2015) Sustainable manufacturing process planning. Int J Adv Manuf Technol 78(5-8):1347–1360

Xu HW (2017) Experimental study on artificial granite material for ultra precision cylindrical grinding machine. (Doctoral dissertation, Zhongyuan Uni of Tech)

Su X, Fan YX (2014) Static and dynamic characteristic analysis of the resin mineral composite material of processing center machine bed. Mach Tool Hydraul 42(21):172–177

Sun J, Li JF, Zhang BJ, Jia XJ (2006) Development of polyester artificial composite granite and its engineering application. Manuf Tech Mach Tool 8:85–87

Zhao HY, Yu HC, Zhao ZX, Hu GM, He HQ (2012) Current status and development of the application of artificial granite on machine foundation parts. Manuf Tech Mach Tool 12:64–67

Fan YW, Li CY, Wang Y (2014) Application of artificial marble bed in electrochemical machining equipment. Aeronaut Manuf Technol 456(12):90–93

Song ZY, Shang YC, Zhao JG (2008) Application of artificial marble bed in ordinary CNC grinder. Precise Manuf Autom 2:27–27

Song SL (2011) Evaluation method for carbon emissions of machine tools based on LCA and its application. (Doctoral dissertation, Chongqing Uni)

Deng ZH, Lv LS, Fu YH, Wan LL (2017) Assessing carbon emission of machine tool parts from life cycle perspective and emission reduction strategy research. Chin J Mech Eng 53(11):144–156

Zhou GH, Zhou C, Lu Q, Tian CL, Xiao ZD (2017) Feature-based carbon emission quantitation strategy for the part machining process. Int J Comput Integr Manuf 11:1–20

Dong XW (2013) A critical review on carbon footprint. J Zhejiang Gongshang Univ 1(2):67–75

National Bureau of Statistics (2008) China statistical yearbook. China Statistics Press, Beijing (in Chinese). http://www.stats.gov.cn/

Gutowski T, Dahmus J, Thiriez A (2006) Electrical energy requirements for manufacturing processes. Energy 2

Dai FZ, Wu D, Wang DY, Du C, Liu XL, Yi SY (2011) Analysis on assessment and application of carbon footprint of industrial production process. Ecol Econ (in Chinese)

Yan K, Zuo JM, Hong Y (2017) Study on dynamic characteristics of resin mineral composite grinding machine bed. Equip Manuf Technol 10:210–213

Na HM, Gao CK, Guo YH, Tian F (2019) CO2 emissions characteristics and source analysis of “Chinese Style” electric arc furnace steelmaking route. J Northeast Univ (Nat Sci) 40(2):212–217

Zhang BM (2006) Energy consumption in foundry production. Modern Cast Iron 26(5):58–60

Ma ZH (2002) Comparative study on greenhouse gas emission coefficient of several major energy sources in China. (Doctoral dissertation, Beijing: China Institute of Atomic Energy)

Yu Y (2016) Research on assessment for energy and carbon emissions of boring and milling machine based on virtual manufacturing. (Doctoral dissertation, Harbin Institute of Tech)

Xie J, Jin XY (2001) Machine tool coating and coating technology. Chemical Industry Press Material Science and Engineering Publishing Center

Taddese G, Durieux S, Duc E (2020) Sustainability performance indicators for additive manufacturing: a literature review based on product life cycle studies. Int J Adv Manuf Technol 107(7-8):1–26

Huang N, Wang HT, Fan CD, Zhou SC, Hou P, Yang J (2012) LCA data quality assessment and control based on uncertainty and sensitivity analysis. Acta Scien Circum 32(6):1529–1536

Xu XN, Chen Y, Zhang SS, Zhang Y, Song GB (2013) Life cycle assessment of composite portland cement. Acta Scien Circum 33(9):2632–2638

Wang Q (2016) Analysis of chemical building materials carbon footprint based on life cycle assessment. (Doctoral dissertation, Hebei Uni of Tech.)

Funding

This manuscript is based upon work supported by Fund name: National Key R&D Project of China (2018YFB2002104), Ministry of Industry and Information Technology of the People’s Republic of China under Grant (201656261-1-3), The Shandong Provincial Natural Science Foundation, China (ZR2017BEE018).

Author information

Authors and Affiliations

Contributions

Yan Ma and Fangyi Li contributed to the conception of the study. Yan Ma contributed significantly to analysis and manuscript preparation. Yan Ma performed the data analyses and wrote the manuscript. Liming Wang, Geng Wang and Lin Kong helped perform the analysis with constructive discussions.

Corresponding author

Ethics declarations

Competing interests

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Ethical approval

(Not applicable)

Consent to participate

(Not applicable)

Consent to publish

(Not applicable)

Code availability

(Not applicable)

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, Y., Li, F., Wang, L. et al. Life cycle carbon emission assessments and comparisons of cast iron and resin mineral composite machine tool bed in China. Int J Adv Manuf Technol 113, 1143–1152 (2021). https://doi.org/10.1007/s00170-021-06656-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06656-9