Abstract

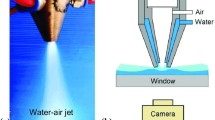

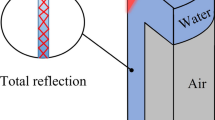

The emergence of a novel technology, curved water jet fiber (CWJF)-guided laser, will broaden the application of water jet-guided laser in surface high precision and no damage micromachining, such as micro-texture treatment, drilling and grooving, etc., of inclined and curved workpiece, in particular, like some large and heavy parts that are difficult to move and rotate. In addition, the novel scheme of high precision, low damage, and circular section processing with the transmission laser and cooling effect of CWJF will be investigated. In this study, the parametric control of water jet deflection is explored using the model of the deflection trajectory of water jet discretized into continuously released water droplets under a nonuniform electric field, in which results show that large deflection angle and displacement can be obtained with high voltage, small distance, and low velocity. Optical transmission system models of CWJF-guided laser under related parametric groups are established through 3D physical reconstruction models of CWJF by using the deflection trajectory. The theoretical calculation of meeting total reflection conditions of incident rays and visualization analyses of CWJF formed-guided laser indicate laser beam can be transmitted effectively. The laser beam is still confined to CWJF and transmitted forward. The methods and results presented in this study will provide the theoretical support and reference for the control of CWJF formation and research of characteristics about CWJF-guided laser during this novel technology development journey.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

Nagimova A, Perveen A (2019) A review on laser machining of hard to cut materials. Mater Today: Proc 18:2440–2447. https://doi.org/10.1016/j.matpr.2019.07.092

Tangwarodomnukun V, Khamwiset K, Qi H (2019) Investigation into laser machining of carbon fiber reinforced plastic in a flowing water layer. Int J Adv Manuf Technol 104:3629–3645. https://doi.org/10.1007/s00170-019-04131-0

Sun D, Han F, Ying W (2019) The experimental investigation of water jet–guided laser cutting of CFRP. Int J Adv Manuf Technol 102:719–729. https://doi.org/10.1007/s00170-018-03218-4

Deng C, Yeo H, Ki H (2020) Electrodynamic simulation of laser beam propagation in waterjet-guided laser processing. Opt Express 28:11128–11143. https://doi.org/10.1364/OE.389497

Braunmüller F, Jérémie D, Gregoire L, Amédée Z, Bernold R (2020) Advanced sensors: Industry 4.0 for the laser microjet technology. Proc. SPIE 11268, Laser-based Micro- and Nanoprocessing XIV,112681 M. https://doi.org/10.1117/12.2544247

Jun W, Gerrit TH (2019) As fast as laser, as precise as EDM. Synova.ch articles. https://www.synova.ch/company/communication.html#articles. Accessed 12 Mar 2020

Tabie VM, Koranteng MO, Yunus A, Kuuyine F (2019) Water-jet guided laser cutting technology-an overview. Lasers Manuf Mater Process 6:189–203. https://doi.org/10.1007/s40516-019-00089-9

Shi Y, Jiang Z, Cao J, Ehmann KF (2020) Texturing of metallic surfaces for superhydrophobicity by water jet guided laser micro-machining. Appl Surf Sci 500:144286. https://doi.org/10.1016/j.apsusc.2019.144286

Kim K, Kim T, Lee C (2013) Analysis of a laser assisted milling process with inclination angles. Int J Precis Eng Manuf 14:1495–1499. https://doi.org/10.1007/s12541-013-0201-0

Mullick S, Agrawal AK, Nath AK (2016) Effect of laser incidence angle on cut quality of 4 mm thick stainless steel sheet using fiber laser. Opt Laser Technol 81:168–179. https://doi.org/10.1016/j.optlastec.2016.02.006

Shi Y, Cao J, Ehmann KF (2017) Curved Water Jet Guided Laser Micro - Manufacturing. Presentation in Smart Manufacturing Series. https://additivemanufacturingseries.com/wp-content/uploads/2017/10/Shi-Yi.pdf. Accessed 20 Sep 2019

Colladon D (1842) On the reflections of a ray of light inside a parabolic liquid stream. C R 15:800–802

Gaebelein J, Hribar J (2020) In Colladon’s Footsteps. Photon Views 4:55–57. https://doi.org/10.1002/phvs.202000033

Parker AE (1928) Liquid jets falling through an electric field. J Opt Soc Am 17:451–453 https://www.osapublishing.org/josa/abstract.cfm?uri=josa-17-6-451

Taylor GW (1972) Liquid optical fibers. Appl Opt 11:786–790. https://doi.org/10.1364/AO.11.000786

Rajabi A, Morad MR, Rahbari N, Pejman Sereshkeh SR, Razavi M (2018) Liquid jet trajectory and droplet path influenced by combined cross flow and electric fields. Chem Eng Sci 181:114–121. https://doi.org/10.1016/j.ces.2018.01.029

Chiarot PR, Jones TB (2009) Dielectrophoretic deflection of ink jets. J Micromech Microeng 19:125018. https://doi.org/10.1088/0960-1317/19/12/125018/meta

Vajdi Hokmabad B, Faraji S, Ghaznavi Dizajyekan T, Sadri B, Esmaeilzadeh E (2014) Electric field-assisted manipulation of liquid jet and emanated droplets. Int J Multiphase Flow 65:127–137. https://doi.org/10.1016/j.ijmultiphaseflow.2014.03.009

Doak WJ, Donovan JP, Chiarot PR (2013) Deflection of continuous droplet streams using high-voltage dielectrophoresis. Exp Fluids 54:1577. https://doi.org/10.1007/s00348-013-1577-4

Tao Q, Li G (2014) Simulation study on 3D trajectory of dielectrophoretic force assembled nanowires. IEEE pp 355-358. https://ieeexplore.ieee.org/abstract/document/6917489

Mohanty S, Ehmann KF, Cao J (2015) Numerical analysis of the effect of non uniform electric field on the trajectory of micro water jet. ASME Int Manuf Sci Eng Conf. https://doi.org/10.1115/MSEC2015-9445

Mohanty S, Ehmann KF, Cao J (2016) Manipulation of Water jet trajectory by a nonuniform electric field in water jet material processing. ASME J Micro Nano Manuf 4:021003-1-9. https://doi.org/10.1115/1.4032904

Shi Y, Cao J, Ehmann KF (2018) Response of high-pressure micro water jets to static and dynamic nonuniform electric fields. ASME J Micro Nano Manuf 6:21006. https://doi.org/10.1115/1.4039507

Huang Y, Zhao Y, Yang L, Zhou J, Jiao H, Long Y (2019) Theoretical study of water jet guided laser technology based on non-uniform electric field deflection water jet. Opt Commun 442:31–39. https://doi.org/10.1016/j.optcom.2019.01.071

Synova SA (2020) Web brochure technology. https://www.synova.ch/technology/technology-benefits.html. Accessed 21 Mar 2020

Persichetti G, Testa G, Bernini R (2015) Optofluidic jet waveguide enhanced Raman spectroscopy. Sensor Actuators B Chem 207:732–739. https://doi.org/10.1016/j.snb.2014.10.060

Li CQ, Yan LJ, Wang Y, Tang J (2011) Simulation on the effects of misaligned coupling on the output intensity distribution in water-jet guided laser. Adv Mater Res 211-212:400–405 www.scientific.net/AMR.211-212

Yang LJ, Li CQ, Tang J, Wang Y, Chen YB (2011) Analysis on the coupling error of laser and water-jet in water-jet guided laser micromachining. Adv Mater Res 188:190–194 https://www.scientific.net/AMR.188.190

Ng EY, Guannan D (2015) The stability of 30-μm-diameter water jet for jet-guided laser machining. Int J Adv Manuf Technol 78:939–946. https://doi.org/10.1007/s00170-014-6692-8

Abbasi Monfared M, Sheikhi M, Kasiri N, Mohammadi T (2018) Experimental investigation of oil-in-water microfiltration assisted by dielectrophoresis: operational condition optimization. Chem Eng Res Des 137:421–433. https://doi.org/10.1016/j.cherd.2018.08.002

Gurav MM, Gupta U, Dabade UA (2019) Quality evaluation of precision micro holes drilled using pulsed Nd:YAG laser on aerospace nickel-based superalloy. Mater Today: Proceedings. 19: 575–582. https://doi.org/10.1016/j.matpr.2019.07.736

Lawrence J (2018) Advances in laser materials processing: technology, research and applications. second edition. Woodhead Publishing, an imprint of Elsevier. https://doi.org/10.1016/C2015-0-05718-5

Shenyang Head Science & Technology Co.,Ltd. https://www.hdwaterjet.com/. Accessed 26 Nov 2019

Scott (2008) Showing that water is a polar molecule, physics & physical science demos. Labs, and Projects for High School Teachers. https://teachingphysics.wordpress.com. Accessed 15 Apr 2020

Green NG, Ramos A, Morgan H (2002) Numerical solution of the dielectrophoretic and travelling wave forces for interdigitated electrode arrays using the finite element method. J Electrost 56:235–254. https://doi.org/10.1016/S0304-3886(02)00069-4

Feng JJ, Krishnamoorthy S, Chen Z J, Makhijani VB (2002) Numerical and analytical studies of ac electric field in dielectrophoretic electrode arrays. 2nd International Conference on Computational Nanoscience and Nanotechnology. https://briefs.techconnect.org/wpcontent/volumes/ICCN2002/pdf/269.pdf. Accessed 20 March 2020

Wagner F, Sibailly O, Vágó N (2003) The laser micro-jet technology-10 years of development. ICALEO, M401. https://doi.org/10.2351/1.5060119

Sterling AM, Sleicher CA (1975) The instability of capillary jets. J Fluid Mech 68:477–495. https://doi.org/10.1017/S0022112075001772

Porter JA, Louhisalmi YA, Karjalainen JA, Füger S (2007) Cutting thin sheet metal with a water jet guided laser using various cutting distances, feed speeds and angles of incidence. Int J Adv Manuf Technol 33:961–967. https://doi.org/10.1007/s00170-006-0521-7

Zahra, Al-Timimi JMA (2019) Investigation of the semiconductor laser beam propagation through air and pure water (stable and turbulence). Iraqi Laser Sci J 1:7–14. https://www.researchgate.net/publication/340088298

Brissinger D, Parent G, Boulet P (2014) Experimental study on radiation attenuation by a water film. J Quant Spectrosc Radiat Transf 145:160–168. https://doi.org/10.1016/j.jqsrt.2014.04.020

Acknowledgments

Thanks to master Rongwei XU, master Guanghui ZHANG, and doctor Tielin SHI, who provided some assistance and contributions at the later stage of manuscript review and during the process of revised manuscript.

Funding

This work was financially supported and funded by the National Natural Science Foundation of China (NSFC) (62004050), the key project of Guangxi Natural Science Foundation (2019JJD160010), the Innovation Project of Guangxi Graduate Education (YXYJYX25, JGY2018061, JGY2019074), the GUET Excellent Graduate Thesis Program (18YJPYSS02, 18YJPYBS01), the Innovation Project of GUET Graduate Education (2020YCXS010), and the innovation team of Guangxi high school and outstanding scholar program.

Author information

Authors and Affiliations

Contributions

Yuxing Huang put forward research ideas, design research methods, and establish analysis models. Linfan Yang was responsible for data collection, sorting, and storage in the early stage. En Liang was responsible for literature collection, tracking, and sorting. Zhixian Zhong was involved in manuscript writing instruction. Yuhong Long carried out framework layout, key point analysis, and guidance for manuscript. All the authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, Y., Yang, L., Liang, E. et al. Study on the mechanisms of curved water jet fiber-guided laser technology. Int J Adv Manuf Technol 112, 3137–3150 (2021). https://doi.org/10.1007/s00170-020-06552-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06552-8