Abstract

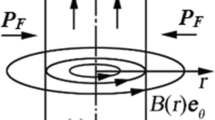

Electro-arc machining (EAM) is a novel type of electrical discharge machining (EDM) that adopts high-energy arc discharges to erode workpiece materials. The workpiece polarity and the dielectric medium flushing have complex effects on the machining process and the EAM results. To fully understand these effects is beneficial to reveal the mechanism of EAM. Two single-pulsed arc discharge experiments with factors, namely, workpiece polarity and flushing pressure, were conducted. As the experimental results, the craters were measured using the microscopy images and surface profiles. The experiments found clear evidence of the polarity effect. The arc root diameter of positive workpiece polarity was smaller than that of negative workpiece polarity, while the crater diameter of positive workpiece polarity was bigger than that of negative workpiece polarity. Additionally, the effects of flushing are obvious. The arc plasma was moved along the flushing direction, which turned the common round crater into a crater with a tail. The crater depth was unaffected by workpiece polarity in the experiments and grew bigger when flushing was adopted, which means that flushing was beneficial to the material removal in EAM. It was deduced that the material removal appeared in the head of the crater mostly while the tail was composed of neglectable pits. The bulge height was increased slowly with an increase in flushing pressure, which was against good gap state and high material removal. Based on the results of the experiments, it is suggested that the EAM processes should adopt both arc-breaking methods to get better machining results.

Similar content being viewed by others

References

Zhang M, Zhang Q, Dou L, Zhu G, Dong C (2016) An independent discharge status detection method and its application in EAM milling. Int J Adv Manuf Technol 87(1-4):909–918

Shrivastava PK, Pandey S, Dangi S (2019) Electrical arc machining: process capabilities and current research trends. Proc Inst Mech Eng C J Mech Eng Sci 233(15):5190–5200

Li Q, Yang X (2020) Study on arc plasma movement and its effect on crater morphology during single-pulse discharge in EDM. Int J Adv Manuf Technol 106(2):5033–5047. https://doi.org/10.1007/s00170-020-04964-0

Zhang M, Zhang Q, Wang H, Liu G, Guo T (2015) Research on a single pulse discharge to discriminate EDM and EAM based on the plasma tunnel and crater geometry. J Mater Process Technol 219:248–256

Zhao W, Gu L, Xu H, Li L, Xiang X (2013) A novel high efficiency electrical erosion process–blasting erosion arc machining. Procedia CIRP 6:621–625

Zhang M, Zhang Q, Dou L, Liu Q, Dong C (2015) Effects of flushing on electrical discharge machining and electro-arc machining. Proc Inst Mech Eng B J Eng Manuf 230(2):293–302. https://doi.org/10.1177/0954405415598463

Bhattacharya S, Tiwari N, Mishra A, Mitra S, Dey G, Ghorui S (2019) Underwater electrical discharges: temperature, density and basic instability features with different anode materials. Plasma Chem Plasma Process 39(4):1019–1048

Gu L, Zhu Y, He G, Farhadi A, Zhao W (2019) Coupled numerical simulation of arc plasma channel evolution and discharge crater formation in arc discharge machining. Int J Heat Mass Transf 135:674–684

Jipeng C, Lin G, Wansheng Z, GUAGLIANO M, (2020) Simulation of temperature distribution and discharge crater of SiCp/Al composites in a single-pulsed arc discharge. Chin J Aeronaut. https://doi.org/10.1016/j.cja.2020.05.033

Zhang M, Zhang Q, Dou L, Liu Q, Dong C (2016) Comparisons of single pulse discharge crater geometries in EDM and EAM. J Manuf Process 22:74–81

Dong H, Li M, Liu T, Zhou Y, Shen Y, Ma C, Zhang X, Liu Y (2019) Mechanism study of sinking electrical discharge machining using water-in-oil nanoemulsion. Int J Adv Manuf Technol 105(5-6):2309–2320

Zhu Y, Gu L, Farhadi A, He G, Zhao W (2019) Observation and analyzation of plasma channel evolution behavior in air flushing electrical arc machining. Int J Adv Manuf Technol 100(9-12):3127–3138

Zhu Y, Farhadi A, He G, Liu X, Gu L, Zhao W (2018) Influence of gap air flushing on plasma channel and crater geometry in single blasting erosion arc discharge. Procedia Cirp 68:210–214

Zhu G, Zhang M, Zhang Q, Xing Q, Yao Z (2020) Investigation of a single-pulse electrical arc discharge in vacuum based on the crater morphology and discharge channel. Int J Adv Manuf Technol 107:3437–3448. https://doi.org/10.1007/s00170-020-05163-7

Chen X, Zhou J, Wang K, Xu Y, Hu G (2020) Experimental research on the influence of dielectrics on short electric arc machining of GH4169. J Braz Soc Mech Sci Eng 42(1):1–12

Dong H, Liu Y, Li M, Liu T, Zhou Y, Li D, Shen Y (2019) High-speed compound sinking machining of Inconel 718 using water in oil nanoemulsion. J Mater Process Technol 274:116271

Kou Z, Han F, Wang G (2019) Research on machining Ti6Al4V by high-speed electric arc milling with breaking arcs via mechanical-hydrodynamic coupling forces. J Mater Process Technol 271:499–509

Farhadi A, Zhu Y, Gu L, Zhao W (2019) Electric arc sweep milling of open channels. Int J Adv Manuf Technol 102(1-4):673–683

Secker P, Sanger C, Lewis T (1972) Behaviour of low-current arcs on moving electrodes. J Phys D Appl Phys 5(3):580

Kunieda M, Kameyama A (2010) Study on decreasing tool wear in EDM due to arc spots sliding on electrodes. Precis Eng 34(3):546–553. https://doi.org/10.1016/j.precisioneng.2010.01.009

Macedo FT (2018) Fundamental investigation of dry EDM plasmas. Dissertation, ETH Zurich. https://doi.org/10.3929/ethz-b-000314422

Teste P, Leblanc T, Chabrerie J-P (1995) Study of the arc root displacement and three-dimensional modelling of the thermal phenomena occurring in a hollow cathode submitted to an electric moving arc. J Phys D Appl Phys 28(5):888

Funding

The work is financially supported by grants from the National Natural Science Foundation of China (Grant Nos. 51705236, 51775260), the Scientific Research Fund for High-level Talents in Nanjing Institute of Technology (YKJ201701), Postgraduate Research & Practice Innovation Program of Jiangsu Province (SJCX19_0499), and the Qing Lan Project in Jiangsu Province of China.

Author information

Authors and Affiliations

Contributions

Min Zhang designed the study, performed the research, and wrote the paper. Xi Jiang conducted the experiments and measured the data. Yong Feng and Binghui Jia analyzed the data. Jian Wang carried out additional analyses and finalized this paper. All authors discussed the results and revised the manuscript.

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, M., Jiang, X., Feng, Y. et al. Effects of workpiece polarity and flushing pressure on the arc plasma and the crater of single-pulsed arc discharges. Int J Adv Manuf Technol 112, 1593–1600 (2021). https://doi.org/10.1007/s00170-020-06549-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06549-3