Abstract

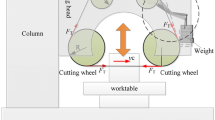

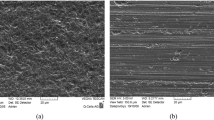

The silicon slicing efficiency and quality of silicon wafer seriously affect the cost of solar power generation and the development of photovoltaic energy industry. This paper proposed an improved cooling and lubrication method using a water tank bath for diamond wire sawing. Compared with the traditional jet sawing with array nozzles, it can be found that the surface roughness is better, no matter the average roughness value, the skewness coefficient, or the kurtosis coefficient, especially in high production efficiency processing. Similar conclusions can also be obtained from the comparative analysis of surface profile distribution and SEM micrographs. This is because the bath sawing can make full use of the cooling and lubricating capability of the cutting fluid, so that the diamond wire can achieve better fluid-carrying effect with the same directionality as the sawing direction into the cutting zone. Furthermore, the service life of diamond wire in bath sawing is longer and wire consumption is lower.

Similar content being viewed by others

References

Schmid F, Khattak CP (1982) Silicon slicing by fixed abrasive slicing technique. Silicon Ingot Casting 43: 14–44

Xavior MA, Adithan M (2009) Determining the influence of cutting fluids on tool wear and surface roughness during turning of AISI 304 austenitic stainless steel. J Mater Process Technol 209:900–909

Mohsan AUH, Liu ZQ, Padhy GK (2017) A review on the progress towards improvement in surface integrity of Inconel 718 under high pressure and flood cooling conditions. Int J Adv Manuf Technol 91:107–125

Sharma VS, Sachdeva A (2012) Comparative analysis of turning under minimum quantity of lubrication, flood cooling and dry conditions. In: AES-ATEMA International Conference Series - Advances and Trends in Engineering Materials and their Applications 331–338

Wang Y, Murga A, Long Z (2021) Experimental study of oil mist characteristics generated from minimum quantity lubrication and flood cooling. Energy Built Environ 2(1): 45-55

Ezugwu EO, Bonney J, Silva RBD (2007) Surface integrity of finished turned Ti–6Al–4V alloy with PCD tools using conventional and high pressure coolant supplies. Int J Mach Tools Manuf 47(6):884–891

NTC Komatsu. (2012) PV500HD Instruction Manual - Polysilicon Wafer Manufacturing Device. Toyama: Japan, 11–60

Heiber J, Bloch R, Bucher R (2011) A review of diamond wire wafering technology at Meyer Burger Ltd. Manufacture of Solar Future - The 2011 Production Annual. Photovol Int 78–85

Meyer Burger. MB Wire Saw DW291 - Mastering Diamond Wire Technology. Gwalt (thun) CH: SWITZERLAND, 2018: 1–3

GAOCE (2020) Sample Book of GC700 Photovoltaic Slicer. http://www.gaoce.cc/en/productshow.php?cid=47&id=111. Accessed 2020-01-20

Lauvray H, Talpied A, Besselere JP (1981) New Wire Silicon Slicing Technology for Solar Cell. In: Palz W. (eds) Photovoltaic Solar Energy Conference. Springer, Dordrecht. https://doi.org/10.1007/978-94-009-8423-3_92

Ning PH, Zhou JW, Liu YL (2008) Study on the capability of adhesion of monocrystalline Si wafer cutting fluid. Semicond Technol 11:50–53

Kumar A, Melkote SN (2018) Diamond wire sawing of solar silicon wafers: a sustainable manufacturing alternative to loose abrasive slurry sawing. Procedia Manuf 21:549–566

Chang L, Jeng YR, Chang L (2013) Effects of negative skewness of surface roughness on the contact and lubrication of nominally flat metallic surfaces. P I Mech Eng J-J Eng 227(6):559–569

Whitehouse DJ (2002) Handbook of surface roughness and nanometrology. Institute of Physics Publishing, Bristol, UK

Tayebi N, Polycarpou AA (2004) Modeling the effect of skewness and kurtosis on the static friction coefficient of rough surfaces. Tribol Int 37(6):491–505

ISO 4287. Geometrical product specifications (GPS) – surface texture: profile method – terms, definitions and surface texture parameters (1st edition). Geneve: Switzerland, 1996-12–01

Mitutoyo. (2009) Mitutoyo SJ210 Surface Profiler. Kanagawa: Japan:18, 21–22

Keyence (2012) Parameters of line roughness. https://www.keyence.com.cn/ss/products/microscope/roughness/line/tab06_c.jsp. Accessed 2020-01-20

Bastos FS, Oliveira EA, Fonseca LG, Vargas SM, Las Casas EB (2016) A FEM-based study on the influence of skewness and kurtosis surface texture parameters in human dental occlusal contact. J Comput Appl Math:139–148

Wang J, Yao C, Peng W (2013) Experimental study of free abrasive wire sawing mechanism. China Mech Eng 24(9):1146–1149

Acknowledgments

The authors acknowledge the support provided by the Development and Construction Fund of National Independent Innovation Demonstration Zone of Shandong Peninsula, Shandong, China, by allowing the facilities to conduct this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qiu, J., Li, X. & Zhang, S. Research on an improved bath cooling and lubrication method for diamond wire sawing. Int J Adv Manuf Technol 112, 2123–2132 (2021). https://doi.org/10.1007/s00170-020-06430-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06430-3