Abstract

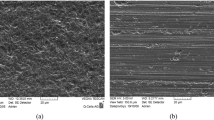

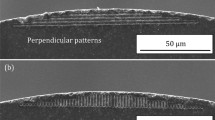

Focused ultrasound-assisted diamond wire sawing (DWS) is proposed in order to improve the sawing performance in terms of sawing force, surface finish, and edge chippings. Under the streaming effect of acoustic wave, the diamond wire saw is forced to move at high frequency. The highest acoustic pressure is obtained at the focal point according to the distribution of scattered waves. A series of sawing experiments with focused ultrasound assistance are accomplished. The influence of wire speed and normal load on sawing forces and surface quality is studied. It is shown that the tangential forces decrease with the increase of wire saw speed. Sawing forces with focused ultrasound assistance are always smaller than that under the traditional condition with the same cutting parameters. Typically, a reduction of 56.0% can be obtained for friction factors. Under the effect of acoustic cavitation and streaming, burrs can be effectively removed from the cutting zone. Furthermore, high ductile removal region can be produced, resulting in better surface finish. During focused ultrasound-assisted DWS, only a few tiny edge chippings appear and a reduction of 56.6% in the maximum edge chip width is provided. Due to the cavitation and cleaning effects, less particles and agglomeration are found on the on the wire surface.

Similar content being viewed by others

References

Wang JS, Fang FZ (2021) Nanometric cutting mechanism of silicon carbide. CIRP Ann Manuf Technol 70:29–32

Xiao HP, Wang HR, Yu N, Liang RG, Tong Z, Chen Z, Wang JH (2019) Evaluation of fixed abrasive diamond wire sawing induced subsurface damage of solar silicon wafers. J Mater Process Technol 273:116267

Wang PZ, Ge PQ, Gao YF, Bi WB (2017) Prediction of sawing force for single-crystal silicon carbide with fixed abrasive diamond wire saw. Mat Sci Semicon Proc 63:25–32

Cao F, Chen KX, Zhang JJ, Ye XY, Li JJ, Zou S, Su XD (2015) Next-generation multi-crystalline silicon solar cells: diamond-wire sawing, nano-texture and high efficiency. Sol Energ Mat Sol C 141:132–138

Yang ZC, Zhu LD, Zhang GX, Ni CB, Lin B (2020) Review of ultrasonic vibration-assisted machining in advanced materials. Int J Mach Tools Manuf 156:103594

Li Z, Yuan SM, Ma J, Shen J, Batako ADL (2021) Study on the surface formation mechanism in scratching test with different ultrasonic vibration forms. J Mater Process Technol 294:117108

Molaie MM, Akbari J, Movahhedy MR (2016) Ultrasonic assisted grinding process with minimum quantity lubrication using oil-based nanofluids. J Clean Prod 129:212–222

Verma GC, Pandey PM, Dixit US (2018) Modeling of static machining force in axial ultrasonic-vibration assisted milling considering acoustic softening. Int J Mech Sci 136:1–16

Feng YX, Hsu FC, Lu YT, Lin YF, Lin CT, Lin CF, Lu YC, Liang SY (2021) Force prediction in ultrasonic vibration assisted milling. Mach Sci Technol 25:307–330

Feng YX, Hsu FC, Lu YT, Lin YF, Lin CT, Lin CF, Lu YC, Lu XH, Liang SY (2020) Surface roughness prediction in ultrasonic vibration-assisted milling. J Adv Mech Des Syst 14:19–00661

Feng YX, Hsu FC, Lu YT, Lin YF, Lin CT, Lin CF, Lu YC, Liang SY (2020) Tool wear rate prediction in ultrasonic vibration-assisted milling. Mach Sci Technol 24:758–780

Liedke T, Kuna M (2011) A macroscopic mechanical model of the wire sawing process. Int J Mach Tools Manuf 51:711–720

Wang Y, Wang R, Li SS, Liu JG, Song LX (2022) Prediction and verification of wafer surface morphology in ultrasonic vibration assisted wire saw (UAWS) slicing single crystal silicon based on mixed material removal mode. Int J Adv Manuf Technol 120:6789–6806

Wang Y, Li DL, Ding ZJ, Liu JG, Wang R (2019) Modeling and verifying of sawing force in ultrasonic vibration assisted diamond wire sawing (UAWS) based on impact load. Int J Mech Sci 164:105161

Aktij SA, Taghipour A, Rahimpour A, Mollahosseini A, Tiraferri A (2020) A critical review on ultrasonic-assisted fouling control and cleaning of fouled membranes. Ultrasonics 108:106228

Xu H, He LB, Zhong B, Qiu JM, Tu J (2019) Classification and prediction of inertial cavitation activity induced by pulsed high-intensity focused ultrasound. Ultrason Sonochem 56:77–83

Poulain S, Guenoun G, Gart S, Crowe W, Jung S (2015) Particle motion induced by bubble cavitation. Phys Rev Lett 114:214501

Lv L, Zhang YX, Zhang YN, Zhang YN (2019) Experimental investigations of the particle motions induced by a laser-generated cavitation bubble. Ultrason Sonochem 56:63–76

Ma Y, Zeng Z, Xu W, Bai L (2021) Directional transport and random motion of particles in alf ultrasonic cavitation structure. Ultrason Sonochem 72:105439

Yosioka K, Kawasima Y (1955) Acoustic radiation pressure on a compressible sphere. Acustica 5:167–173

Wei W, Thiessen DB, Marston PL (2004) Acoustic radiation force on a compressible cylinder in a standing wave. J Acoust Soc Am 116:201–208

Muller PB, Barnkob R, Jensen M, Bruus H (2012) A numerical study of microparticle acoustophoresis driven by acoustic radiation forces and streaming-induced drag forces. Lab on a Chip 12:4617–4627

Louisnard O (2017) A viable method to predict acoustic streaming in presence of cavitation. Ultrason. Sonochem 35:518–524

Pishchalnikov YA, Gutierrez J, Dunbar WW, Philpott RW (2016) Intense cavitation at extreme static pressure. Ultrasonics 65:380–389

Mirad MM, Das B (2021) A critical review of the state of the art literature in the monitoring of ultrasonic machining process and tool failure prediction. Eng Fail Anal 130:105769

Liu W, Tang D, Liu RT, Deng ZH, Gu H, Liu S (2022) Ductile regime grinding of silicon nitride ceramics based on dynamic critical grinding depth. Int J Adv Manuf Technol 121:6431–6438

Zhang H, Pei YC, Liu QJ, Wang LL (2021) An ultrasonic vibration-assisted system development for inner-diameter sawing hard and brittle material. J Mater Process Technol 295:117155

Tesfay HD, Xu ZG, Li ZC (2016) Ultrasonic vibration assisted grinding of bio-ceramic materials: an experimental study on edge chippings with Hertzian indentation tests. Int J Adv Manuf Technol 86:3483–3494

Funding

The authors would like to acknowledge the support of the “National Natural Science Foundation of China (Grant No. 52275403).”

Author information

Authors and Affiliations

Contributions

Lutao Yan: investigation, methodology, formal analysis, writing—original draft, writing—review and editing, funding acquisition.

Xiuhong Chen: conceptualization, methodology, validation, investigation.

Haiyuan Li: project administration, resources, writing—review and editing.

Qinjian Zhang: resources, supervision, project administration.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yan, L., Chen, X., Li, H. et al. Investigation on focused ultrasound-assisted diamond wire sawing of silicon carbide. Int J Adv Manuf Technol 128, 3251–3259 (2023). https://doi.org/10.1007/s00170-023-12164-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12164-9