Abstract

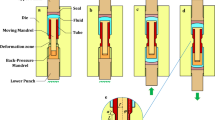

In this study, hydrostatic tube cyclic expansion extrusion (HTCEE) at elevated temperatures was utilized to produce relatively long ultrafine-grained (UFG) AM60 magnesium alloy tubes. HTCEE method is able to apply large strains to tubular parts and produce long UFG tubes without changing their dimensions due to the reduction of the friction at interfaces using high-pressure molten polymeric fluid at an elevated temperature. This method is performed on an AM60 magnesium alloy at an elevated temperature of 300 °C, and the microstructure and mechanical properties were examined. The results represent a significant enhancement of the mechanical properties and a dramatic reduction in the grain size. The yield and ultimate strength were increased to 160 MPa and 328 MPa after first passes of HTCEE from the primary values of 130 MPa and 212 MPa; also the elongation to failure increased to 31% from 9%. Microhardness was increased to about 72 Hv after the HTCEE process from the primary value of 50 Hv. Microstructural results showed a significant grain refinement to a grain size of ~ 3 μm after the process from the primary value of ~ 160 μm. Finite element results exhibit a very significant (~ 85% reduction) decrease in the required load and increase in the strain homogeneity in the HTCEE process compared to its conventional counterpart. This method seems to be very promising for future industrial applications.

Similar content being viewed by others

References

Kim H, Estrin Y, Bush M (2000) Plastic deformation behaviour of fine-grained materials. Acta Mater 48:493–504

Valiev R (1999) I. Alexandrov. Nanostruct Mater 12:35–40

Valiev RZ, Islamgaliev RK, I.V. Alexandrov, Progress in materials science, 45 (2000) 103-189.

Olejnik L, Rosochowski A (2005) Technical Sciences, 53

Valiev RZ, Langdon TG (2006) Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog Mater Sci 51:881–981

Saito Y, Utsunomiya H, Tsuji N, Sakai T (1999) Novel ultra-high straining process for bulk materials—development of the accumulative roll-bonding (ARB) process. Acta Mater 47:579–583

Zhang J (2007) Materials Science Forum, Trans Tech Publ, pp. 2293-2300.

Pardis N, Talebanpour B, Ebrahimi R, Zomorodian S (2011) Mater Sci Eng A 528:7537–7540

Zhilyaev AP, Langdon TG (2008) Using high-pressure torsion for metal processing: Fundamentals and applications. Prog Mater Sci 53:893–979

Ensafi M, Faraji G, Abdolvand H (2017) Cyclic extrusion compression angular pressing (CECAP) as a novel severe plastic deformation method for producing bulk ultrafine grained metals. Mater Lett 197:12–16

Faraji G, Kim H (2017) Review of principles and methods of severe plastic deformation for producing ultrafine-grained tubes. Mater Sci Technol 33:905–923

Tóth L, Arzaghi M, Fundenberger J, Beausir B, Bouaziz O, Arruffat-Massion R (2009) Severe plastic deformation of metals by high-pressure tube twisting. Scr Mater 60:175–177

Mohebbi M, Akbarzadeh A (2010) Accumulative spin-bonding (ASB) as a novel SPD process for fabrication of nanostructured tubes. Mater Sci Eng A 528:180–188

Faraji G, Mashhadi MM, Kim HS (2011) Tubular channel angular pressing (TCAP) as a novel severe plastic deformation method for cylindrical tubes. Mater Lett 65:3009–3012

Faraji G, Mashhadi MM, Kim HS (2012) Deformation behavior in tubular channel angular pressing (TCAP) using triangular and semicircular channels. Mater Trans 53:8–12

Shapourgan O, Faraji G (2016) Rubber pad tube straining as a new severe plastic deformation method for thin-walled cylindrical tube. In: Proceedings of the institution of mechanical engineers. Part B: J Eng Manuf 230:1845–1854

Ahmadkhanbeigi M, Shapourgan O, Faraji G (2017) Microstructure and mechanical properties of Al tube processed by friction stir tube back extrusion (FSTBE). Trans Indian Inst Met 70(7):1849–1856

Chan W, Fu M, Yang B (2011) Study of size effect in micro-extrusion process of pure copper. Mater Des 32:3772–3782

Altan T, Ngaile G, Shen G (2005) Cold and hot forging: fundamentals and applications, ASM international

Swiostek J, Göken J, Letzig D, Kainer K (2006) Hydrostatic extrusion of commercial magnesium alloys at 100°C and its influence on grain refinement and mechanical properties. Mater Sci Eng A 424:223–229

Jamali S, Faraji G, Abrinia K (2017) Hydrostatic radial forward tube extrusion as a new plastic deformation method for producing seamless tubes. Int J Adv Manuf Tech 88(1–4):291–301

Yuan R, Wu Z, Cai H, Zhao L, Zhang X (2016) Effects of extrusion parameters on tensile properties of magnesium alloy tubes fabricated via hydrostatic extrusion integrated with circular ECAP. Mater Des 101:131–136

Samadpour F, Faraji G, Babaie P, Bewsher S, Mohammadpour M (2018) Hydrostatic cyclic expansion extrusion (HCEE) as a novel severe plastic deformation process for producing long nanostructured metals. Mater Sci Eng A 718:412–417

Motallebi Savarabadi M, Faraji G, Zalnezhad E (2019) Hydrostatic tube cyclic expansion extrusion (HTCEE) as a new severe plastic deformation method for producing long nanostructured tubes. J Alloys Compd 785:163–168

Hung J-C, Hung C (2000) The design and development of a hydrostatic extrusion apparatus. J Mater Process Technol 104:226–235

Skiba J, Pachla W, Mazur A, Przybysz S, Kulczyk M, Przybysz M, Wróblewska M, J Mater Process technology, 214 (2014) 67-74.

Babaei A, Mashhadi M, Jafarzadeh H (2014) Tube cyclic expansion-extrusion (TCEE) as a novel severe plastic deformation method for cylindrical tubes. J Mater Sci 49:3158–3165

Rhee K, Han W, Park H, Kim S (2004) Fabrication of aluminum/copper clad composite using hot hydrostatic extrusion process and its material characteristics. Mater Sci Eng A 384:70–76

Balasundar I, Raghu T (2010) Effect of friction model in numerical analysis of equal channel angular pressing process. Mater Des 31:449–457

Samadpour F, Faraji G, Babaie P, Bewsher S, Mohammadpour M (2018) Hydrostatic cyclic expansion extrusion (HCEE) as a novel severe plastic deformation process for producing long nanostructured metals. Mater Sci Eng A 718:412–2417

Chen Q, Zhao Z, Chen G, Wang B (2015) Effect of accumulative plastic deformation on generation of spheroidal structure, thixoformability and mechanical properties of large-size AM60 magnesium alloy. J Alloys Compd 632:190–200

Wu M, Xiong S (2011) Microstructure Characteristics of the Eutectics of Die Cast AM60B Magnesium Alloy. J Mater Sci Technol 27:1150–1156

Faraji G, Kim HS, Kashi HT (2018) Severe plastic deformation: methods, processing and properties. Elsevier, Amsterdam

Galiyev A, Kaibyshev R, Gottstein G (2001) Acta Mater 49:1199–1207

Guo W, Wang Q, Ye B, Liu M, Peng T, Liu X, Zhou H (2012) Enhanced microstructure homogeneity and mechanical properties of AZ31 magnesium alloy by repetitive upsetting. Mater Sci Eng A 540:115–122

Panigrahi S, Yuan W, Mishra R, DeLorme R, Davis B, Howell R, Cho K (2011) A study on the combined effect of forging and aging in Mg–Y–RE alloy. Mater Sci Eng A 530:28–35

She J, Pan F, Guo W, Tang A, Gao Z, Luo S, Song K, Yu Z, Rashad M (2016) Effect of high Mn content on development of ultra-fine grain extruded magnesium alloy. Mater Des 90:7–12

Xu S, Kamado S, Matsumoto N, Honma T, Kojima Y (2009) Recrystallization mechanism of as-cast AZ91 magnesium alloy during hot compressive deformation. Mater Sci Eng A 527:52–60

Minárik P, Král R, Čížek J, Chmelík F (2016) Effect of different c/a ratio on the microstructure and mechanical properties in magnesium alloys processed by ECAP. Acta Mater 107:83–95

Yamashita A, Horita Z, Langdon TG (2001) Improving the mechanical properties of magnesium and a magnesium alloy through severe plastic deformation. Mater Sci Eng A 300:142–147

Stanford N, Barnett M (2013) Solute strengthening of prismatic slip, basal slip and twinning in Mg and Mg–Zn binary alloys. Int J Plast 47:165–181

Koike J, Kobayashi T, Mukai T, Watanabe H, Suzuki M, Maruyama K (2003) K. Higashi. Acta Mater 51:2055–2065

Chino Y, Kobata M, Iwasaki H, Mabuchi M (2003) An investigation of compressive deformation behaviour for AZ91 Mg alloy containing a small volume of liquid. Acta Mater 51:3309–3318

Máthis K, Gubicza J, Nam N (2005) Microstructure and mechanical behavior of AZ91 Mg alloy processed by equal channel angular pressing. J Alloys Compd 394:194–199

Akbaripanah F, Fereshteh-Saniee F, Mahmudi R, Kim H (2013) Microstructural homogeneity, texture, tensile and shear behavior of AM60 magnesium alloy produced by extrusion and equal channel angular pressing. Mater Des 43:31–39

Amani S, Faraji G, Abrinia K (2017) Microstructure and hardness inhomogeneity of fine-grained AM60 magnesium alloy subjected to cyclic expansion extrusion (CEE). J Manuf Process 28:197–208

Kulyasova O, Islamgaliev R, Mingler B, Zehetbauer M (2009) Microstructure and fatigue properties of the ultrafine-grained AM60 magnesium alloy processed by equal-channel angular pressing. Mater Sci Eng A 503:176–180

Estrin Y (2013) A. Vinogradov. Acta Mater 61:782–817

Raab G, Soshnikova E, Valiev R (2004) Mater Sci Eng A 387:674–677

Yang Z, Kan B, Li J, Su Y, Qiao L (2017) Hydrostatic pressure effects on stress corrosion cracking of X70 pipeline steel in a simulated deep-sea environment. Int J Hydrog Energy 42:27446–27457

Faraji G, Babaei A, Mashhadi MM, Abrinia K (2012) Parallel tubular channel angular pressing (PTCAP) as a new severe plastic deformation method for cylindrical tubes. Mater Lett 77:82–85

Nagasekhar A, Chakkingal U (2006) P. Venugopal. J Mater Process Technol 173:53–60

Jamali S, Faraji G, Abrinia K (2017) Hydrostatic radial forward tube extrusion as a new plastic deformation method for producing seamless tubes. Int J Adv Manuf Technol 88:291–301

Torabzadeh H, Faraji G, Zalnezhad E (2016) Cyclic Flaring and Sinking (CFS) as a New Severe Plastic Deformation Method for Thin-walled Cylindrical Tubes. Trans Indian Inst Metals 69:1217–1222

Dorinson A, Ludema KC (1985) Mechanics and chemistry in lubrication. Elsevier

Faraji G, Samadpour F, Babaei P (2018) US Patent App. 15/725,232

Funding

This work was supported by the Iranian National Science Foundation (INSF).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Samadpour, F., Faraji, G. & Savarabadi, M.M. Processing of long ultrafine-grained AM60 magnesium alloy tube by hydrostatic tube cyclic expansion extrusion (HTCEE) under high fluid pressure. Int J Adv Manuf Technol 111, 3535–3544 (2020). https://doi.org/10.1007/s00170-020-06352-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06352-0