Abstract

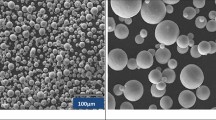

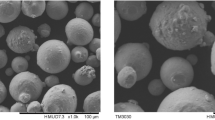

Cellular biomaterials with highly controlled microstructures are auspicious materials for medical orthopedics applications either as scaffold or implants due to their capability of encouraging better osseointegration and cell proliferation. This work focuses on the design and optimization of the hip implant by introducing a cellular structure into a solid implant to allow bone tissue ingrowth and reduce stress shielding. The cellular hip implant is incorporated with vintiles lattice topologies having different strut thickness and unit cell sizes to achieve the requirements of bone ingrowth and biomechanical mimic strength. All four optimized cellular hip implants with different unit cell size and porosity were manufactured via selective laser melting (SLM) using the Ti6Al4V material. To predict the mechanical property of hip cellular implant, finite element analysis (FEA) was employed and optimization methods were used for improving the mechanical performance of the hip cellular implant. To evaluate the reduction in stiffness of hip cellular implants, experimental tests were performed based on ISO 7206-4(2010) under static loading conditions. The experimental and simulation force-displacement results show that the optimized cellular hip implant has 62% lower stiffness than its solid counterpart. Moreover, the cellular hip implant was 50% lower in weight than the solid implant. Finally, the result of this study shows that the cellular implants with porosity of 56% and 58% have the potential to be used in orthopedic and prosthetic applications to improve osseointegration.

Similar content being viewed by others

References

Gibson LJ (2005) Biomechanics of cellular solids. J Biomech 38:377–399. https://doi.org/10.1016/j.jbiomech.2004.09.027

Nazir A, Abate KM, Kumar A, Jeng JY (2019) A state-of-the-art review on types, design, optimization, and additive manufacturing of cellular structures. Int J Adv Manuf Technol 104:3489–3510. https://doi.org/10.1007/s00170-019-04085-3

Bobyn JD, Pilliar RM, Cameron HU, Weatherly GC (1980) The optimum pore size for the fixation of porous surfaced metal implants by the ingrowth of bone. Clin Orthop Relat Res NO 150:263–270. https://doi.org/10.1097/00003086-198007000-00045

Beaupré GS, Orr TE, Carter DR (1990) An approach for time-dependent bone modeling and remodeling—theoretical development - Beaupré - 2005 - Journal of Orthopaedic Research - Wiley Online Library. J Orthop Res 8(5):651–661

Coelho PG, Fernandes PR, Rodrigues HC, Cardoso JB, Guedes JM (2009) Numerical modeling of bone tissue adaptation-a hierarchical approach for bone apparent density and trabecular structure. J Biomech 42:830–837. https://doi.org/10.1016/j.jbiomech.2009.01.020

Fujibayashi S, Neo M, Kim HM, Kokubo T, Nakamura T (2004) Osteoinduction of bioactive titanium metal. In: Key Engineering Materials. Trans Tech Publications Ltd 254:953–956

Cheng XYY, Li SJJ, Murr LEE et al (2012) Compression deformation behavior of Ti-6Al-4V alloy with cellular structures fabricated by electron beam melting. J Mech Behav Biomed Mater 16:153–162. https://doi.org/10.1016/j.jmbbm.2012.10.005

Spoerke ED, Murray NG, Li H, Brinson LC, Dunand DC, Stupp SI (2005) A bioactive titanium foam scaffold for bone repair. Acta Biomater 1:523–533. https://doi.org/10.1016/j.actbio.2005.04.005

Wang X, Xu S, Zhou S, Xu W, Leary M, Choong P, Qian M, Brandt M, Xie YM (2016) Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: a review. Biomaterials 83:127–141. https://doi.org/10.1016/j.biomaterials.2016.01.012

Olivares AL, Marsal È, Planell JA, Lacroix D (2009) Finite element study of scaffold architecture design and culture conditions for tissue engineering. Biomaterials 30:6142–6149. https://doi.org/10.1016/j.biomaterials.2009.07.041

Zhang Z, Jones D, Yue S, Lee PD, Jones JR, Sutcliffe CJ, Jones E (2013) Hierarchical tailoring of strut architecture to control permeability of additive manufactured titanium implants. Mater Sci Eng C 33:4055–4062. https://doi.org/10.1016/j.msec.2013.05.050

Kapfer SC, Hyde ST, Mecke K, Arns CH, Schröder-Turk GE (2011) Minimal surface scaffold designs for tissue engineering. Biomaterials. 32:6875–6882. https://doi.org/10.1016/j.biomaterials.2011.06.012

Yan C, Hao L, Hussein A, Young P (2015) Ti-6Al-4V triply periodic minimal surface structures for bone implants fabricated via selective laser melting. J Mech Behav Biomed Mater 51:61–73. https://doi.org/10.1016/j.jmbbm.2015.06.024

Melchels FPW, Barradas AMC, Van Blitterswijk CA et al (2010) Effects of the architecture of tissue engineering scaffolds on cell seeding and culturing. Acta Biomater 6:4208–4217. https://doi.org/10.1016/j.actbio.2010.06.012

Gibson LJ, Ashby MF (1982) The mechanics of three-dimensional cellular materials. Proc R Soc A Math Phys Eng Sci 382:43–59. https://doi.org/10.1098/rspa.1982.0088

Lalvani H (2011) Int J Space Struct 26(3):139–154

Heinl P, Müller L, Körner C, Singer RF, Müller FA (2008) Cellular Ti-6Al-4V structures with interconnected macro porosity for bone implants fabricated by selective electron beam melting. Acta Biomater 4:1536–1544. https://doi.org/10.1016/j.actbio.2008.03.013

Xiao Z, Wang Z, Yang B, Zhang X (2015) Bioceramic scaffolds. Biomater Regen Med:151–182. https://doi.org/10.1017/CBO9780511997839.013

Sullivan RM, Ghosn LJ, Lerch BA (2008) A general tetrakaidecahedron model for open-celled foams. Int J Solids Struct 45:1754–1765. https://doi.org/10.1016/J.IJSOLSTR.2007.10.028

Jang WY, Kraynik AM, Kyriakides S (2008) On the microstructure of open-cell foams and its effect on elastic properties. Int J Solids Struct 45:1845–1875. https://doi.org/10.1016/j.ijsolstr.2007.10.008

Roberts AP, Garboczi EJ (2002) Elastic properties of model random three-dimensional open-cell solids. J Mech Phys Solids 50:33–55. https://doi.org/10.1016/S0022-5096(01)00056-4

Knorr T, Heinl P, Schwerdtfeger J, Körner C, Singer RF, Etzold BJM (2012) Process specific catalyst supports-selective electron beam melted cellular metal structures coated with microporous carbon. Chem Eng J 181-182:725–733. https://doi.org/10.1016/j.cej.2011.10.009

Campoli G, Borleffs MS, Amin Yavari S, Wauthle R, Weinans H, Zadpoor AA (2013) Mechanical properties of open-cell metallic biomaterials manufactured using additive manufacturing. Mater Des 49:957–965. https://doi.org/10.1016/j.matdes.2013.01.071

Li SJ, Xu QS, Wang Z, Hou WT, Hao YL, Yang R, Murr LE (2014) Influence of cell shape on mechanical properties of Ti–6Al–4V meshes fabricated by electron beam melting method. Acta Biomater 10:4537–4547. https://doi.org/10.1016/J.ACTBIO.2014.06.010

Parthasarathy J, Starly B, Raman S (2011) A design for the additive manufacture of functionally graded porous structures with tailored mechanical properties for biomedical applications. J Manuf Process 13:160–170. https://doi.org/10.1016/j.jmapro.2011.01.004

Xiao L, Song W, Wang C, Tang H, Liu N, Wang J (2016) Yield behavior of open-cell rhombic dodecahedron Ti–6Al–4V lattice at elevated temperatures. Int J Mech Sci 115-116:310–317. https://doi.org/10.1016/j.ijmecsci.2016.07.006

Jung JW, Park JH, Hong JM, Kang HW, Cho DW (2014) Octahedron pore architecture to enhance flexibility of nasal implant-shaped scaffold for rhinoplasty. Int J Precis Eng Manuf 15:2611–2616. https://doi.org/10.1007/s12541-014-0634-0

Kadkhodapour J, Montazerian H, Darabi AC, Anaraki AP, Ahmadi SM, Zadpoor AA, Schmauder S (2015) Failure mechanisms of additively manufactured porous biomaterials: effects of porosity and type of unit cell. J Mech Behav Biomed Mater 50:180–191. https://doi.org/10.1016/j.jmbbm.2015.06.012

Babaee S, Jahromi BH, Ajdari A, Nayeb-Hashemi H, Vaziri A (2012) Mechanical properties of open-cell rhombic dodecahedron cellular structures. Acta Mater 60:2873–2885. https://doi.org/10.1016/J.ACTAMAT.2012.01.052

Yan C, Hao L, Hussein A, Bubb SL, Young P, Raymont D (2014) Evaluation of light-weight AlSi10Mg periodic cellular lattice structures fabricated via direct metal laser sintering. J Mater Process Technol 214:856–864. https://doi.org/10.1016/j.jmatprotec.2013.12.004

Yan C, Hao L, Hussein A, Young P, Huang J, Zhu W (2015) Microstructure and mechanical properties of aluminium alloy cellular lattice structures manufactured by direct metal laser sintering. Mater Sci Eng A 628:238–246. https://doi.org/10.1016/j.msea.2015.01.063

Giannitelli SM, Accoto D, Trombetta M, Rainer A (2014) Current trends in the design of scaffolds for computer-aided tissue engineering. Acta Biomater 10:580–594. https://doi.org/10.1016/j.actbio.2013.10.024

Thijs L, Verhaeghe F, Craeghs T, Humbeeck JV, Kruth JP (2010) A study of the microstructural evolution during selective laser melting of Ti-6Al-4V. Acta Mater 58:3303–3312. https://doi.org/10.1016/j.actamat.2010.02.004

Abate KM, Nazir A, Chen JE, Jeng JY (2020) Design, optimization, and evaluation of additively manufactured vintiles cellular structure for acetabular cup implant. Processes 8(1):25

Gu D, Shen Y (2009) Balling phenomena in direct laser sintering of stainless steel powder: metallurgical mechanisms and control methods. Mater Des 30:2903–2910. https://doi.org/10.1016/j.matdes.2009.01.013

Li R, Shi Y, Wang Z, Wang L, Liu J, Jiang W (2010) Densification behavior of gas and water atomized 316L stainless steel powder during selective laser melting. Appl Surf Sci 256:4350–4356. https://doi.org/10.1016/j.apsusc.2010.02.030

Abate KM, Nazir A, Yeh YP, Chen JE, Jeng JY (2019) Design, optimization, and validation of mechanical properties of different cellular structures for biomedical application. Int J Adv Manuf Technol 106:1253–1265. https://doi.org/10.1007/s00170-019-04671-5

Hollister S (2006) Porous scaffold design for tissue engineering. Nat Mater 5:590. https://doi.org/10.1038/nmat1683

Beyer C, Figueroa D (2016) Design and analysis of lattice structures for additive manufacturing. J Manuf Sci Eng Trans ASME 138:1–15. https://doi.org/10.1115/1.4033957

Choy SY, Sun CN, Leong KF, Wei J (2017) Compressive properties of functionally graded lattice structures manufactured by selective laser melting. Mater Des 131:112–120. https://doi.org/10.1016/j.matdes.2017.06.006

Qiu C, Yue S, Adkins NJE, Ward M, Hassanin H, Lee PD, Withers PJ, Attallah MM (2015) Influence of processing conditions on strut structure and compressive properties of cellular lattice structures fabricated by selective laser melting. Mater Sci Eng A 628:188–197. https://doi.org/10.1016/j.msea.2015.01.031

Pattanayak DK, Fukuda A, Matsushita T, Takemoto M, Fujibayashi S, Sasaki K, Nishida N, Nakamura T, Kokubo T (2011) Bioactive Ti metal analogous to human cancellous bone: fabrication by selective laser melting and chemical treatments. Acta Biomater 7:1398–1406. https://doi.org/10.1016/j.actbio.2010.09.034

Delikanli YE, Kayacan MC (2019) Design, manufacture, and fatigue analysis of lightweight hip implants. J Appl Biomater Funct Mater 17:228080001983683. https://doi.org/10.1177/2280800019836830

Sivasankar M (2007) Failure analysis of hip prosthesis (Doctoral dissertation)

Badiche X, Forest S, Guibert T, Bienvenu Y, Bartout JD, Ienny P, Croset M, Bernet H (2000) Mechanical properties and non-homogeneous deformation of open-cell nickel foams: application of the mechanics of cellular solids and of porous materials. Mater Sci Eng A 289:276–288. https://doi.org/10.1016/S0921-5093(00)00898-4

Gibson L, Ashby M (1999) Cellular solids: structure and properties. Syndicate of the University of Cambridge, Cambridge

Zheng Y, Xu X, Xu Z, Wang J, Cai H (2017) Titanium implants based on additive manufacture. Metallic biomaterials: new directions and technologies, 1st edn. Wiley-VCH Verlag GmbH & Co. KGaA, 255–291

Nouri A, Hodgson PD, Wen C (2010) Biomimetic porous titanium scaffolds for. Biomimetics Learn from Nat 415–450

Dzogbewu T, Monaheng L, Els J, et al (2016) Evaluation of the compressive mechanical properties of cellular DMLS. Proc 17th Annu Int Conf rapid prod Dev Assoc South Africa, no 978-0-620-72061–8, 2016 1–12

Funding

This work was financially supported by the High-Speed 3D Printing Research Center (Grant No. 108P012) from the Featured Areas Research Center Program within the framework of the Higher Education Sprout Project by the Minister of Education (MOE), Taiwan, and also financially supported by the Department of Biomedical Engineering, National Defense Medical Center, Taipei 11490, Taiwan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abate, K.M., Nazir, A. & Jeng, JY. Design, optimization, and selective laser melting of vin tiles cellular structure-based hip implant. Int J Adv Manuf Technol 112, 2037–2050 (2021). https://doi.org/10.1007/s00170-020-06323-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06323-5