Abstract

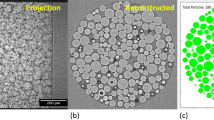

Different additive manufacturing (AM) technologies can help produce parts from various materials, but in order to achieve consistent and predictable properties and ensure high quality of 3D-printed objects, these materials shall possess specific properties. In this research, we studied initial properties of a cobalt-chrome-molybdenum–based superalloy powder by using sophisticated techniques such as the scanning electron microscopy (SEM) with an energy-dispersive X-ray spectrometer (EDS), X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), Auger electron spectroscopy (AES) and particle-induced X-ray emission (PIXE). The summarised results have shown dispersion of main components (Co, Cr, Mo), an attenuating of Co0.64Cr0.32Mo0.04 with Co0.9Mo0.1 phase, and differences in size, shape, surface roughness, structure and content of S, C, Mn and Si among individual particles. Depending on the particle surface structure, differences in the oxidation of particles have been found. According to Auger survey spectra, the smallest particles had a low concentration of Co and Cr oxides, while the smooth ones had higher contents of metal oxides. These findings could be used to predict behaviour of particles during the additive manufacturing process.

Similar content being viewed by others

References

van Noort R (2012) The future of dental devices is digital. Dent Mater 28:3–12. https://doi.org/10.1016/j.dental.2011.10.014

Hennen L, Moniz A.B, Torgersen H, Torgersenm J (2018) Additive bio-manufactur3D printing for medical recovery and human enhancement, European Parliamentary Research Service. Scientific Foresight Unit (STOA). PE 614.571. pp. 133. https://doi.org/10.2861/923327

Uriondo A, Esperon-Miguez M, Perinpanayagam S (2015) The present and future of additive manufacturing in the aerospace sector: a review of important aspects, Part G. J Aerospace Eng 229:2132–2147. https://doi.org/10.1177/0954410014568797

Baumers M, Dickens P, Tuck C, Hague R (2016) The cost of additive manufacturing: machine productivity, economies of scale and technology-push. Technol Forecast Soc Chang 102:193–201. https://doi.org/10.1016/j.techfore.2015.02.015

Goharian A, Abdullah MR (2017) Bioinert metals (stainless steel, titanium, cobalt chromium). https://doi.org/10.1016/B978-0-12-804634-0.00007-0

Giacchi VJ, Morando NC, Fornaro O, Palacio HA (2011) Microstructural characterization of as-cast biocompatible Co – Cr – Mo alloys Mater. Charact 62:53–61. https://doi.org/10.1016/j.matchar.2010.10.011

Zhang M, Yang Y, Song C, Bai Y, Xiao Z (2018) Hide details An investigation into the aging behavior of CoCrMo alloys fabricated by selective laser melting. Journal of Alloys and Compounds 750(25):878–886. https://doi.org/10.1088/1757-899X/100/1/012033

Taddei E, Henriques VAR, Silva CRM, Cairo CAA (2004) Production of new titanium alloy for orthopedic implants. Mater Sci Eng C 24(5):683–687. https://doi.org/10.1016/j.msec.2004.08.011

Disegi J (2000) Titanium alloys for fracture fixation implants. Injury 31:D14–D17. https://doi.org/10.1016/S0020-1383(00)80017-0

Hodgson AWE, Kurz S, Virtanen S, Fervel V, Olsson C, Mischler S (2004) Passive and transpassive behavior of CoCrMo in simulated biological solutions. Electrochim Acta 49:2167. https://doi.org/10.1016/j.electacta.2003.12.043

Hiromoto S, Onodera E, Chiba A, Asami K, Hanawa T (2005) Microstructure and corrosion behavior in biological environments of the new forged low-Ni Co–Cr–Mo alloys. Biomaterials. 26:4912–4923. https://doi.org/10.1016/j.biomaterials.2005.01.028

Marcus P (2002) Corrosion mechanisms in theory and practice, 2nd edn. Marcel Dekker, USA. https://doi.org/10.1201/9780203909188

Zhang X, Li Y, Tang N, Onodera E, Chiba A (2014) Corrosion behaviour of CoCrMo alloys in 2 wt% sulphuric acid solution. Electrochim Acta 125:543–555. https://doi.org/10.1016/j.electacta.2014.01.143

Huang P, López HF (1999) Strain induced ε-martensite in a Co–Cr–Mo alloy: grain size effects. Mater Lett 39:244–248. https://doi.org/10.1016/S0167-577X(99)00021-X

Ueki K, Kurihara Y, Mineta S, Alfirano UK, Namba S, Yoneda T, Narushima T (2016) Changes in microstructure of biomedical Co-Cr-Mo alloys during aging at 973 to 1373 K. Mater Trans. 57:2048–2053Opris et al., 2007. https://doi.org/10.2320/matertrans.MI201507

Opris CD, Liu R, Yao MX, Wu XJ (2007) Development of Stellite alloy composites with sintering/HIPing technique for wear-resistant applications. Mater Des 28:581–591. https://doi.org/10.1016/j.matdes.2005.08.004

Human AM, Roebuck B, Exner HE (1998) Electrochemical polarization and corrosion behavior of cobalt and Co(W, C) alloys in 1 N sulphuric acid. Mater Sci Eng A 241:202. https://doi.org/10.1016/S0921-5093(97)00492-9

Potgieter J, Thanjekwayo N, Olubambi P, Maledi N, Potgieter-Vermaak SS (2011) Influence of Ru additions on the corrosion behaviour of WC-Co cemented carbide alloys in sulphuric acid. Int J Refract Met Hard Mater. 29:478. https://doi.org/10.1016/j.ijrmhm.2011.02.007

Nakayama H (1997) Dentistry and metal allergy. Dental-Diamond Co, London, pp 22–27

Lee SH, Takahashi E, Nomura N, Chiba (2005) A effect of heat treatment on microstructure and mechanical properties of Ni- and C-free Co-CrMo alloys for medical applications. Mater Trans 46(8):1790–1793. https://doi.org/10.2320/matertrans.46.1790

Karimi S, Nickchi T, Alfantazi A (2011) Effects of bovine serum albumin on the corrosion behaviour of AISI 316L, Co–28Cr–6Mo, and Ti–6Al–4V alloys in phosphate buffered saline solutions. Corrosion Science 53:3262–3272. https://doi.org/10.1016/j.corsci.2011.06.009

Merritt K, Brown SA (1988) Effect of proteins and pH on fretting corrosion and metalion release. J Biomed Mater Res 22:111–120. https://doi.org/10.1002/jbm.820220204

Lundin M, Hedberg Y, Jiang T, Herting G, Wang X, Thormann E, Blomberg E, Wallinder IO (2012) Adsorption and protein-induced metal release from chromium metal and stainless steel. J Colloid Interface Sci 366(1):155–164. https://doi.org/10.1016/j.jcis.2011.09.068

Talha M, Ma Y, Kumar P, Lin Y, Singh A (2019) Role of protein adsorption in the bio corrosion of metallic implants – a review. Colloids Surf B: Biointerfaces 176:494–506. https://doi.org/10.1016/j.colsurfb.2019.01.038

Slotwinski JA, Garboczi EJ, Stutzman PE, Ferraris CF, Watson SS, Peltz MA (2014) Characterization of metal powders used for additive manufacturing. J Res Natl Inst Stand Technol 119. https://doi.org/10.6028/jres.119.018

Campbell JL, Boyd N, Grassi N, Bonnick P, Maxwell JA (2010) The Guelph PIXE software package IV. Nucl Instr and Meth B 268:3356–3363. https://doi.org/10.1016/j.nimb.2010.07.012

Dunkley JJ (2015) ASM Handbook Powder metallurgy, vol 7. ASM International Materials Park, Ohio

Material data sheet: http://ip-saas-eos-cms.s3.amazonaws.com/public/4b839242298b3d77/721463526ca053889c9784ec989f3c88/EOS_CobaltChrome_MP1_en.pdf

Verma H.R (2007) Atomic and nuclear analytical methods. Punjabi University Patiala India https://doi.org/10.1007/978-3-540-30279-7

Surviliene S, Jasulaitiene A, Cesuniene A, Lisowska-Oleksiak A (2008) The use of XPS for the study of the surface layers of Cr-Co alloy electrodeposited from Cr(III) formate-urea baths. Solid State Ionics 179:222–227. https://doi.org/10.1016/j.ssi.2007.12.052

Mori M, Yamanaka K, Kuramoto K, Ohmura K, Ashino T, Chiba A (2015) Effect of carbon on the microstructure, mechanical properties and metal ion release of Ni-free Co–Cr–Mo alloys containing nitrogen. Mater Sci Eng C 55:145–154. https://doi.org/10.1016/j.msec.2015.05.058

Unger WES (2013) Surface analysis—Auger electron spectroscopy, in reference module in chemistry. In: Molecular Sciences and Chemical Engineering. Elsevier

Delgado J, Ciurana J, Rodríguez CA (2012) Influence of process parameters on part quality and mechanical properties for DMLS and SLM with iron-based materials. Int J Adv Manuf Technol 60:601–610. https://doi.org/10.1007/s00170-011-3643-5

Enrique PD, Marzbanrad E, Mahmoodkhani Y, Keshavarzkermani A, Al Momani H, Toyserkani E, Zhou NY (2020) Design of binder jet additive manufactured co-continuous ceramic-reinforced metal matrix composites. J Mater Sci Technol 49:81–90. https://doi.org/10.1016/j.jmst.2020.01.053

Hwang SS, Lim YS, Kim WS (2013) Role of grain boundary carbides in cracking behavior of Ni base alloys. Nucl Eng Technol 45(1):73–80. https://doi.org/10.5516/NET.07.2012.013

Wang S, Cao L, Zhang Z (2019) Influence of carbide morphology on the deformation and fracture mechanisms of spheroidized 14CrMoR steel. Metals 9(11):1221. https://doi.org/10.3390/met9111221

Vizureanu P, Minciuna MG, Iovan G, Stoleriu S (2017) Synthesis, processing, and characterization of the cobalt alloys with silicon addition. In: Khan M (ed) Cobalt. Intech, pp 23–48. https://doi.org/10.5772/intechopen.70886

Funding

This work was supported by the Research Council of Lithuania under project No. S-MIP-19-25.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mordas, G., Jasulaitienė, V., Steponavičiūtė, A. et al. Characterisation of CoCrMo powder for additive manufacturing. Int J Adv Manuf Technol 111, 3083–3093 (2020). https://doi.org/10.1007/s00170-020-06236-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06236-3