Abstract

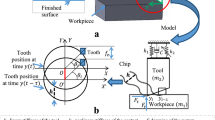

Axial ultrasonic vibration–assisted cutting has been proposed and proved preponderance on cutting performance; however, the transient separation cutting characteristic has not been clearly revealed. This paper focuses on the transient separation cutting characteristic of axial ultrasonic vibration–assisted cutting and its influence on the cutting performance. First, the separation cutting criteria, including feed coefficient and phase shift, are established and influence factors, such as feed rate, amplitude, and phase shift, are systematically analyzed. Subsequently, the duty ratio is deduced and calculated, and some features and a control mechanism are introduced. In addition, a transient separation cutting model with four stages is demonstrated. The reason for the average cutting force reduction by the transient separation cutting characteristic is also stated. Finally, the verification of the separation cutting and transient separation cutting model and the comparison of the feed thrust force and parameter influences on the cutting performance are experimentally performed. The transient signals of different duty ratios 0.55 to 1 are obtained, and 10 to 40% reductions of feed thrust are measured both by a PCB sensor and a Kistler dynamometer. The influence degree of the feed coefficient, spindle rotation speed, and cutting depth on the performance is analyzed. A parameter combination of smaller feed coefficient, moderate spindle rotation speed, and smaller cutting depth is suggested to obtain a better cutting performance by fully considering the cutting force, surface roughness, and tool life.

Similar content being viewed by others

References

Moriwaki T, Shamoto E (1995) Ultrasonic elliptical vibration cutting. CIRP Ann-Manuf Technol 44:31–34. https://doi.org/10.1016/S0007-8506(07)62269-0

Ma CX, Shamoto E, Moriwaki T, Wang LJ (2004) Study of machining accuracy in ultrasonic elliptical vibration cutting. Int J Mach Tools Manuf 44(12–13):1305–1310. https://doi.org/10.1016/j.ijmachtools.2004.04.014

Moriwaki T, Shamoto E (1991) Ultra-precision diamond turning of stainless steel by applying ultrasonic vibration. CIRP Ann-Manuf Technol 40:559–562. https://doi.org/10.1016/S0007-8506(07)62053-8

Xiao M, Wang QM, Sato K, Karube S, Soutome T, Xu H (2006) The effect of tool geometry on regenerative instability in ultrasonic vibration cutting. Int J Mach Tools Manuf 46(5):492–499. https://doi.org/10.1016/j.ijmachtools.2005.07.002

Jin M, Murakawa M (2001) Development of a practical ultrasonic vibration cutting tool system. J Mater Process Technol 113(1–3):342–347. https://doi.org/10.1016/S0924-0136(01)00649-5

Michalski M, Lechner M, Gruber M, Merklein M (2018) Influence of ultrasonic vibration on the shear formability of metallic materials. CIRP Ann-Manuf Technol 67:277–280. https://doi.org/10.1016/j.cirp.2018.04.108

Dong GJ, Wang L, Li C, Yu YF (2020) Investigation on ultrasonic elliptical vibration boring of deep holes with large depth–diameter ratio for high-strength steel 18Cr2Ni4WA. Int J Adv Manuf Technol 108:1527–1539. https://doi.org/10.1007/s00170-020-05531-3

Chen G, Ren CZ, Zou YH, Qin XD, Lu LP, Li SP (2019) Mechanism for material removal in ultrasonic vibration helical milling of Ti6Al4V alloy. Int J Mach Tools Manuf 138:1–13. https://doi.org/10.1016/j.ijmachtools.2018.11.001

Liu QM, Xu JK, Yu HD (2020) Experimental study of tool wear and its effects on cutting process of ultrasonic-assisted milling of Ti6Al4V. Int J Adv Manuf Technol 108:2917–2928. https://doi.org/10.1007/s00170-020-05593-3

Wang Y, Wang Q, Ding ZJ, He DX, Xiong W, Chen SY, Li ZX (2018) Study on the mechanism and key technique of ultrasonic vibration and magnetic field complex assisted WEDM-LS thick shape memory alloy workpiece. J Mater Process Technol 261:251–265. https://doi.org/10.1016/j.jmatprotec.2018.06.006

Jia DZ, Li CH, Zhang YB, Yang M, Zhang XP, Li RZ, Ji HJ (2019) Experimental evaluation of surface topographies of NMQL grinding ZrO2 ceramics combining multiangle ultrasonic vibration. Int J Adv Manuf Technol 100:457–473. https://doi.org/10.1007/s00170-018-2718-y

He JF, Guo ZN, Lian HS, Wang JJ, Liu JW, Chen XL (2019) Study on manufacturing quality of micro-ultrasonic machining with force control. Int J Adv Manuf Technol 105:3137–3146. https://doi.org/10.1007/s00170-019-04438-y

Wang H, Zhang DZ, Li YZ, Cong WL (2020) The effects of elliptical ultrasonic vibration in surface machining of CFRP composites using rotary ultrasonic machining. Int J Adv Manuf Technol 106:5527–5538. https://doi.org/10.1007/s00170-020-04976-w

Wang H, Hu YB, Cong WL, Burks AR (2019) Rotary ultrasonic machining of carbon fiber–reinforced plastic composites: effects of ultrasonic frequency. Int J Adv Manuf Technol 104:3759–3772. https://doi.org/10.1007/s00170-019-04084-4

Ning FD, Wang H, Cong WL (2019) Rotary ultrasonic machining of carbon fiber reinforced plastic composites: a study on fiber material removal mechanism through single-grain scratching. Int J Adv Manuf Technol 103:1095–1104. https://doi.org/10.1007/s00170-019-03433-7

Liu Y, Liu ZB, Wang XB, Huang T (2020) Experimental study on tool wear in ultrasonic vibration–assisted milling of C/SiC composites. Int J Adv Manuf Technol 107:425–436. https://doi.org/10.1007/s00170-020-05060-z

Klocke F, Demmer A, Heselhaus M (2004) Material removal mechanisms in ultrasonic-assisted diamond turning of brittle materials. Int J Mater Prod Technol 20(4):231–238. https://doi.org/10.1504/IJMPT.2004.004249

Mitrofanov AN, Ahmed N, Babitsky VI, Silberschmidt VV (2005) Effect of lubrication and cutting parameters on ultrasonically-assisted turning of Inconel 718. J Mater Process Technol 162-163:649–654. https://doi.org/10.1016/j.jmatprotec.2005.02.170

Cerniway MA (2002) Elliptical diamond milling: kinematics, force, and tool wear. MS Master’s thesis. North Carolina State University. http://www.lib.ncsu.edu/resolver/1840.16/2454

Zhang XQ, Kumar AS, Rahman M, Nath C, Liu K (2012) An analytical force model for orthogonal elliptical vibration cutting technique. J Mater Process Technol 14(3):378–387. https://doi.org/10.1016/j.jmapro.2012.05.006

Guo P, Ehmann KF (2013) An analysis of the surface generation mechanics of the elliptical vibration texturing process. Int J Mach Tools Manuf 64:85–95. https://doi.org/10.1016/j.ijmachtools.2012.08.003

Nath C, Rahman M, Andrew SSK (2007) A study on ultrasonic vibration cutting of low alloy steel. J Mater Process Technol 192-193:159–165. https://doi.org/10.1016/j.jmatprotec.2007.04.047

Muhammad R, Ahmed N, Roy A, Silberschmidt VV (2012) Numerical modelling of vibration-assisted turning of Ti-15333. Procedia CIRP 1:347–352. https://doi.org/10.1016/j.procir.2012.04.062

Babitsky VI, Kalashnikov AN, Meadows A, Wijesundara AAHP (2003) Ultrasonically assisted turning of aviation materials. J Mater Process Technol 132(1–3):157–167. https://doi.org/10.1016/S0924-0136(02)00844-0

Sui H, Zhang XY, Zhang DY, Jiang XG, Wu RB (2017) Feasibility study of high-speed ultrasonic vibration cutting titanium alloy. J Mater Process Technol 247:111–120. https://doi.org/10.1016/j.jmatprotec.2017.03.017

Liu JJ, Jiang XG, Han X, Gao Z, Zhang DY (2019) Effects of rotary ultrasonic elliptical machining for side milling on the surface integrity of Ti-6Al-4V. Int J Adv Manuf Technol 101:1451–1465. https://doi.org/10.1007/s00170-018-2847-3

Liu JJ, Jiang XG, Han X, Zhang DY (2019) Influence of parameter matching on performance of high-speed rotary ultrasonic elliptical vibration-assisted machining for side milling of titanium alloys. Int J Adv Manuf Technol 101:1333–1348. https://doi.org/10.1007/s00170-018-3006-6

Li J, Geng DX, Zhang DY, Qin W, Jiang YG (2018) Ultrasonic vibration mill-grinding of single-crystal silicon carbide for pressure sensor diaphragms. Ceram Int 44(3):3107–3112. https://doi.org/10.1016/j.ceramint.2017.11.077

Geng DX, Teng YD, Liu YH, Shao ZY, Jiang XG, Zhang DY (2019) Experimental study on drilling load and hole quality during rotary ultrasonic helical machining of small-diameter CFRP holes. J Mater Process Technol 270:195–205. https://doi.org/10.1016/j.jmatprotec.2019.03.001

Zhang XY, Sui H, Zhang DY, Jiang XG (2018) Study on the separation effect of high-speed ultrasonic vibration cutting. Ultrasonics 87:166–181. https://doi.org/10.1016/j.ultras.2018.02.016

Zhang XY, Sui H, Zhang DY, Jiang XG (2018) An analytical transient cutting force model of high-speed ultrasonic vibration cutting. Int J Adv Manuf Technol 95:3929–3941. https://doi.org/10.1007/s00170-017-1499-z

Zhang XY, Sui H, Zhang DY, Jiang XG (2018) Measurement of ultrasonic-frequency repetitive impulse cutting force signal. Measurement 129:653–663. https://doi.org/10.1016/j.measurement.2018.06.043

Zhang XY, Lu ZH, Peng ZL, Sui H, Zhang DY (2018) Development of a tool-workpiece thermocouple system for comparative study of the cutting temperature when high-speed ultrasonic vibration cutting Ti-6Al-4V alloys with and without cutting fluids. Int J Adv Manuf Technol 96:237–246. https://doi.org/10.1007/s00170-018-1600-2

Jiang XG, Zhang XY, Zhu XB, Sui H, Zhang DY (2018) Study of phase shift control in high-speed ultrasonic vibration cutting. IEEE T Ind Electron 65(3):2467–2474. https://doi.org/10.1109/TIE.2017.2740827

Singal RK, Singal M, Singal R (2006) Fundamentals of machining and machine tools, vol 2006. I.K. International Publishing ouse Pvt. Ltd, U.K, pp 1–15

Oxley PLB, Hastings WF (1976) Minimum work as a possible criterion for determining the frictional conditions at the tool/chip interface in machining. Philos T R Soc A 282(1310):565–584. https://doi.org/10.1098/rsta.1976.0064

Funding

This work was supported by the Fundamental Research Funds for the Central Universities of Civil Aviation University of China (grant no. 3122019072).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sui, H., Zhang, L., Wang, S. et al. Transient separation cutting characteristic of axial ultrasonic vibration–assisted cutting. Int J Adv Manuf Technol 110, 2407–2425 (2020). https://doi.org/10.1007/s00170-020-06020-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06020-3