Abstract

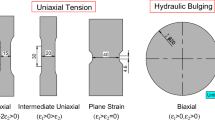

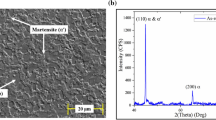

The purpose of this work was to investigate the formability and deformation behavior of DP600 steel sheets during a hybrid forming process composed of quasi-static forming and dynamic high strain rate electrohydraulic forming (EHF) sequence. The results showed that the ultimate limit major strains under the uniaxial tensile strain path were 40–47%, and those under plane strain and biaxial tensile strain paths were 28–31% and 43–57%, respectively. Compared with quasi-static data, the hybrid data under these three strain paths were improved by 30%, 70%, and 36%, respectively, demonstrating a hyperplasticity characteristic. The quasi-static prestrain had little effect on the ultimate formability, and the hyperplasticity effect of the quasi-statically prestrained specimens mainly depended on the inertial effect and the change in constitutive behavior in the high strain rate EHF loading step. Furthermore, the optimized Johnson-Cook constitutive model of the quasi-statically prestrained sheet during high strain rate condition was obtained by means of dynamic Hopkinson tensile tests, and the numerical simulation results based on this material constitutive were in good agreement with that obtained by experiments, showing an error of less than 5%. Then, the numerical simulation reproduced the propagation and evolution process of the pressure wave from ellipsoid to sphere, and quantified the dynamic deformation behavior of the quasi-statically prestrained specimen during an EHF process. The maximum velocity and strain rate of the prestrained specimen during EHF step were 270 m/s and 3700/s, respectively, and the ultimate height of the deformed specimen was 43 mm.

Similar content being viewed by others

References

Luiz MVT, Ravilson ACF, Paulo VPM (2013) Fracture analysis approach of DP600 steel when subjected to different stress/strain states during deformation. Int J Adv Manuf Technol 69:1017–1024

Essam A, Uwe R, Markus S, Oleg M (2013) Biaxial behavior of laser welded DP/TRIP steel sheets. Int J Adv Manuf Technol 68:1075–1082

Psyk V, Risch D, Kinsey BL, Tekkaya AE, Kleiner M (2011) Electromagnetic forming-a review. J Mater Process Technol 211:787–829

Mynors DJ, Zhang B (2002) Applications and capabilities of explosive forming. J Mater Process Technol 125-126:1–25

Balanethiram VS, Daehn GS (1992) Enhanced formability of interstitial free iron at high strain rate. Scr Metall Mater 27:1783–1788

Yu HP, Sun LC, Zhang X, Wang SL, Li CF (2017) Experiments on electrohydraulic forming and electromagnetic forming of aluminum tube. Int J Adv Manuf Technol 89:3169–3176

Yu HP, Zheng QL (2019) Forming limit diagram of DP600 steel sheets during electrohydraulic forming. Int J Adv Manuf Technol 104:743–756

Woodward S, Weddeling C, Daehn G, Psyk V, Carson B, Tekkaya AE (2011) Production of low-volume aviation components using disposable electromagnetic acutators. J Mater Process Technol 211:886–895

Vohnout VJ (1998) A hybrid quasi-static/dynamic process for forming large sheet metal parts from aluminum alloys. The Ohio State University, Ohio

Liu DH, Yu HP, Li CF (2011) Experimental observations of quasi-static-dynamic formability in biaxially strained AA5052-O. J Mater Eng Perform 20:223–230

Shang JH (2006) Electromagnetically assisted sheet metal stamping. The Ohio State University, Ohio

Kamal M, Daehn GS (2007) A uniform pressure electromagnetic actuator for forming flat sheets. J Manuf Sci Eng 129:369–379

Odeshi AG, Ameeri S, Bassim MN (2005) Effect of high strain rate on plastic deformation of a low alloy steel subjected to ballistic impact. J Mater Process Technol 162:385–391

Sandford JE (1970) Recent advances stir interest in high velocity forming. Iron Age Metalworking International October, 1970

Golovashchenko SF (2010) Pulsed electrohydraulic calibration of stamped panels. US Patent 7,827,838B2. Issued on November 9, 2010

Golovashchenko SF, Gillard AJ, Mamutov AV, Ibrahim R (2014) Pulsed electrohydraulic springback calibration of parts stamped from advanced high strength steel. J Mater Process Technol 214:2796–2810

Gillard AJ, Golovashchenko SF, Mamutov AV (2013) Effect of quasi-static prestrain on the formability of dual phase steels in electrohydraulic forming. J Manuf Process 15:201–218

Cheng J, Green DE, Golovashchenko SF (2017) Formability enhancement of DP600 steel sheets in electro-hydraulic die forming. J Mater Process Technol 244:178–189

Balanethiram VS, Hu XY, Daehn GS (1994) Hyperplasticity: enhanced formability at high rates. J Mater Process Technol 45:595–600

Woo MA, Song WJ, Kang BS, Kim J (2019) Evaluation of formability enhancement of aluminum alloy sheet in electrohydraulic forming process with free-bulge die. Int J Adv Manuf Technol 101:1085–1093

Li CF, Liu DH, Yu HP, Ji ZB (2009) Research on formability of 5052 aluminum alloy sheet in a quasi-static-dynamic tensile process. Int J Mach Tool Manu 49:117–124

Maris C, Hassannejadasl A, Green DE, Cheng J, Golovashchenko SF, Gillard AJ, Liang YT (2016) Comparison of quasi-static and electrohydraulic free forming limits for DP600 and AA5182 sheets. J Mater Process Technol 235:206–219

Acknowledgments

The authors would like to take this opportunity to express their sincere appreciation to the National Natural Science Foundation of China.

Funding

This work was financially supported by the National Natural Science Foundation of China [Grant No. 51675128, 51475122].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zheng, Q., Yu, H. & Cai, X. Formability and deformation behavior of DP600 steel sheets during a hybrid quasi-static/dynamic forming process. Int J Adv Manuf Technol 110, 2169–2180 (2020). https://doi.org/10.1007/s00170-020-06014-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06014-1