Abstract

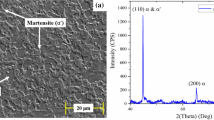

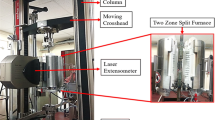

In this study, the deformation and formability characteristics of DP 590 steel have been determined at high temperature. Firstly, theoretical uniaxial flow stress prediction has been studied by modified Arrhenius, Fields–Backofen, Khan–Huang–Liang and modified Fields–Backofen, type constitutive models in different test temperatures (773–1093 K) with strain rates (0.001–0.1 s−1). The flow stress behavior of DP590 steel has been well predicted by the KHL model compared to other models. Furthermore, traditional yield functions such as, Hill 1948 and Barlat 1989, have been formulated. Barlat 1989 exhibits better prediction ability for all test temperatures. Additionally, Nakazima tests have been conducted for experimental determination of formability behavior by means of Forming limit Diagram (FLD), surface strain distribution, limit dome height and thickness distribution. Forming test temperature has significantly affected the formability behavior of the alloy. For theoretical prediction of FLD, Marciniak–Kuczynski (M–K) model has been implemented with different combination of uniaxial constitutive modeling and the yield function. The M–K model with a combination of KHL model with the Barlat 1989 yield function has given the best predictability with a 0.05 average error for all forming test temperatures. Furthermore fractography of the post stretched specimens has revealed a ductile fracture for test temperatures.

Similar content being viewed by others

References

Huh H, Kim SB, Song JH, Lim JH (2008) Dynamic tensile characteristics of TRIP-type and DP-type steel sheets for an auto-body. Int J Mech Sci 50:918–931. https://doi.org/10.1016/j.ijmecsci.2007.09.004

Tasan CC, Diehl M, Yan D et al (2015) An overview of dual-phase steels: advances in microstructure-oriented processing and micromechanically guided design. Annu Rev Mater Res 45:391–431

Pandre S, Kotkunde N, Takalkar P et al (2019) Flow stress behavior, constitutive modeling, and microstructural characteristics of DP 590 steel at elevated temperatures. J Mater Eng Perform 28:7565–7581. https://doi.org/10.1007/s11665-019-04497-y

Roth CC, Mohr D (2014) Effect of strain rate on ductile fracture initiation in advanced high strength steel sheets: experiments and modeling. Int J Plast 56:19–44. https://doi.org/10.1016/j.ijplas.2014.01.003

Chakraborti PC, Mitra MK (2007) Microstructure and tensile properties of high strength duplex ferrite-martensite (DFM) steels. Mater Sci Eng A 466:123–133. https://doi.org/10.1016/j.msea.2007.02.042

Bayramin B, Şimşir C, Efe M (2017) Dynamic strain aging in DP steels at forming relevant strain rates and temperatures. Mater Sci Eng A 704:164–172. https://doi.org/10.1016/j.msea.2017.08.006

Baragar DL (1987) The high temperature and high strain-rate behaviour of a plain carbon and an HSLA steel. J Mech Work Technol 14:295–307. https://doi.org/10.1016/0378-3804(87)90015-5

Beynon ND, Oliver S, Jones TB, Fourlaris G (2005) Tensile and work hardening properties of low carbon dual phase strip steels at high strain rates. Mater Sci Technol 21:771–778. https://doi.org/10.1179/174328405X41038

Sung JH, Kim JH, Wagoner RH (2010) A plastic constitutive equation incorporating strain, strain-rate, and temperature. Int J Plast 26:1746–1771. https://doi.org/10.1016/j.ijplas.2010.02.005

Tsuchida N, Izaki Y, Tanaka T, Fukaura K (2012) Effects of temperature and strain rate on stress-strain curves for dual-phase steels and their calculations by using the Kocks- Mecking model. ISIJ Int 52:729–734. https://doi.org/10.2355/isijinternational.52.729

Curtze S, Kuokkala VT, Hokka M, Peura P (2009) Deformation behavior of TRIP and DP steels in tension at different temperatures over a wide range of strain rates. Mater Sci Eng A 507:124–131. https://doi.org/10.1016/j.msea.2008.11.050

Queiroz RRU, Cunha FGG, Gonzalez BM (2012) Study of dynamic strain aging in dual phase steel. Mater Sci Eng A 543:84–87. https://doi.org/10.1016/j.msea.2012.02.050

Barlat F, Lian K (1989) Plastic behavior and stretchability of sheet metals. Part I: a yield function for orthotropic sheets under plane stress conditions. Int J Plast 5:51–56. https://doi.org/10.1016/0749-6419(89)90019-3

Banabic (2010) Plastic behaviour of sheet metal. Springer, Berlin Heidelberg

Gräber A, Pöhlandt K, Lange K (1989) A new approach to the torsion test for determining flow curves. CIRP Ann - Manuf Technol 38:223–226. https://doi.org/10.1016/S0007-8506(07)62690-0

Ma B, Liu ZG, Jiang Z et al (2016) Prediction of forming limit in DP590 steel sheet forming: an extended fracture criterion. Mater Des 96:401–408. https://doi.org/10.1016/j.matdes.2016.02.034

Pandre S, Morchhale A, Kotkunde N, Singh SK (2020) Influence of processing temperature on formability of thin-rolled DP590 steel sheet. Mater Manuf Process 35:901–909. https://doi.org/10.1080/10426914.2020.1743854

Şimşir C, Cetin B, Efe M, et al (2017) A material perspective on consequence of deformation heating during stamping of DP steels. In: Journal of Physics: Conference Series. Institute of Physics Publishing, p 12059

Dieter GE (2011) Mechanical metallurgy SI metric edition. Mcgraw-Hill Book Company, Koga

ASTM 517–00:2010 (2010) Standard test method for plastic strain ratio r for sheet metal. ASTM 1–8

ASTM E2218–15 (2015) Standard test method for determining forming limit curves. ASTM B. Stand. 1–15

Mahalle G, Morchhale A, Kotkunde N et al (2020) Forming and fracture limits of IN718 alloy at elevated temperatures: experimental and theoretical investigation. J Manuf Process 56:482–499

Mahalle G, Kotkunde N, Gupta AK, Singh SK (2020) Prediction of flow stress behaviour by materials modelling technique for Inconel 718 alloy at elevated temperature. Adv Mater Process Technol 00:1–8. https://doi.org/10.1080/2374068X.2020.1728649

Takuda H, Fujimoto H, Hatta N (1998) Modelling on flow stress of Mg-Al-Zn alloys at elevated temperatures. J Mater Process Technol 80–81:513–516. https://doi.org/10.1016/S0924-0136(98)00154-X

Zhang XH (2003) Experimental and numerical study of magnesium alloy during hot-working process. Doctoral dissertation,. Shanghai Jiaotong University

Xu Z, Huang F (2015) Comparison of constitutive models for FCC metals over wide temperature and strain rate ranges with application to pure copper. Int J Impact Eng 79:65–74. https://doi.org/10.1016/j.ijimpeng.2014.10.003

Samantaray D, Mandal S, Bhaduri AK (2009) A comparative study on Johnson Cook, modified Zerilli-Armstrong and Arrhenius-type constitutive models to predict elevated temperature flow behaviour in modified 9Cr-1Mo steel. Comput Mater Sci 47:568–576. https://doi.org/10.1016/j.commatsci.2009.09.025

Hill R (1990) Constitutive modelling of orthotropic plasticity in sheet metals. J Mech Phys Solids 38:405–417. https://doi.org/10.1016/0022-5096(90)90006-P

Mahalle G, Salunke O, Kotkunde N, et al (2019) Anisotropic yielding behaviour of Inconel 718 alloy at elevated temperatures. In: ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE2019). Salt Lake City, Utah, USA, pp 1–5

Bao Y, Wierzbicki T (2004) On fracture locus in the equivalent strain and stress triaxiality space. Int J Mech Sci 46:81–98. https://doi.org/10.1016/j.ijmecsci.2004.02.006

Marciniak Z, Kuczyński K (1967) Limit strains in the processes of stretch-forming sheet metal. Int J Mech Sci 9:609–620. https://doi.org/10.1016/0020-7403(67)90066-5

Pandre S, Morchhale A, Mahalle G et al (2021) Fracture limit analysis of DP590 steel using single point incremental forming: experimental approach, theoretical modeling and microstructural evolution. Arch Civ Mech Eng 21:95. https://doi.org/10.1007/s43452-021-00243-1

Mahalle G, Kotkunde N, Gupta AK, Singh SK (2021) An improved M-K model coupled with different ductile criteria for fracture limit predictions of Inconel 718 alloy. J Mater Res Technol 11:1162–1174. https://doi.org/10.1016/j.jmrt.2021.01.092

Kuroda M, Tvergaard V (2000) Forming limit diagrams for anisotropic metal sheets with different yield criteria. Int J Solids Struct 37:5037–5059. https://doi.org/10.1016/S0020-7683(99)00200-0

Xu S, Weinmann KJ (1998) Prediction of forming limit curves of sheet metals using Hill’s 1993 user-friendly yield criterion of anisotropic materials. Int J Mech Sci 40:913–925. https://doi.org/10.1016/S0020-7403(97)00145-8

Funding

No.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflict of interest.

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Seshacharyulu, K., Mahalle, G., Kotkunde, N. et al. High temperatures deformation and formability behavior of DP590 steel: mechanical characterization and modeling. J Braz. Soc. Mech. Sci. Eng. 43, 472 (2021). https://doi.org/10.1007/s40430-021-03196-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-021-03196-x