Abstract

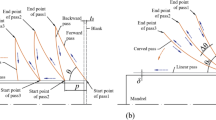

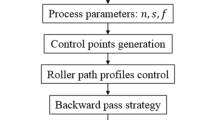

Various approaches to produce non-axisymmetric parts in metal spinning have been developed by researchers. In asymmetric multi-pass spinning, the motion of the roller is synchronized with the mandrel’s rotation by CNC codes to achieve oblique or non-circular shapes. In this study, cylindrical cups are formed using two kinds of oblique pass sets to investigate the effects of different parameters on thickness distribution and forming limit. In the translational pass set, the inclination angle is determined by the difference of the wall depths on two sides of the product and it is determined by the difference of half cone angles in the rotational pass set. The difference of wall thickness distribution in the translational pass is greater than that in the rotational pass and it increases as the inclination angle increases. The difference between the axial distributions on two sides of the wall decreases as the pass pitch increases near the top of the product, and it increases near the edge of the wall. A greater incremental angle does not affect the difference but reduces the uniformity of the wall thickness in the rotational pass set. All the failures are wrinkles in the experiments. Wrinkles occur when the pass pitch or the roller feed ratio is too large. A greater inclination angle reduces the forming limit in the translational pass set and does not affect the forming limit in the rotational pass set.

Similar content being viewed by others

References

Amano T, Tamura K (1984) The study of an elliptical cone spinning by the trial equipment. In: Proceedings of the 3rd international conference on rotary metalworking processes. Kyoto, Japan, pp. 213–224

Gao XC, Kang DC, Meng XF, Wu HJ (1999) Experimental research on a new technology—ellipse spinning. J Mater Process Technol 94(2–3):197–200

Xia Q, Lai Z, Zhan X, Cheng X (2010) Research on spinning method of hollow part with triangle arc-type cross section based on profiling driving. Steel Res Int 81(9):994–998

Arai, H (2005) Robotic metal spinning—forming asymmetric products using force control. In: Proceedings of 2005 IEEE International Conference on Robotics and Automation. Barcelona, Spain. pp. 2702–2707

Jia Z, Han ZR, Xu Q, Peng WF (2014) Numerical simulation and experiment study on hollow spinning process for square cross-section cone. Int J Adv Manuf Technol 75:1605–1612

Sugita Y, Arai H (2015) Formability in synchronous multipass spinning using simple pass set. J Mater Process Technol 217, 336–344

Sekiguchi A, Arai H (2012) Control of wall thickness distribution by oblique shear spinning methods. J Mater Process Technol 212(4):786–793

Han ZR, Fan ZJ, Xiao Y, Jia Z (2016) A research on thickness distribution of oblique cone in dieless shear spinning. Int J Adv Manuf Technol 90:2901–2912

Arai H, Kanazawa T (2018) Synchronous multipass spinning of oblique-bottom shape. J Mater Process Technol 260:66–76

Xiao Y, Han ZR, Fan ZJ, Jia Z (2018) A study of asymmetric multi-pass spinning for angled-flange cylinder. J Mater Process Technol 256:202–215

Funding

This work was financially supported by the Chinese Aeronautical Establishment [2018ZE54028].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiao, Y., Han, Z., Zhou, S. et al. Experimental study of asymmetric multi-pass spinning. Int J Adv Manuf Technol 110, 667–679 (2020). https://doi.org/10.1007/s00170-020-05913-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05913-7