Abstract

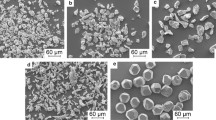

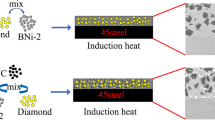

Diamond-copper/steel matrix abrasive composites were prepared by the roll-bonding technique. Firstly, the effects of the roll-bonding technical parameters (including sintering parameters, rolling parameters, and the component content) on the interfacial bonding strength in the composites were researched. Then, the surface macroscopic characteristics of the composites and the microstructures of the bonding interfaces were observed. The static compressive strength of the diamonds in the composites and the grinding performance of the composites were measured. Finally, the mechanisms for the effects of the roll-bonding technical parameters on the interfacial bonding strength were explored. The results showed that with increasing those parameters, the interfacial bonding strength between diamonds and the matrices displayed an initial increase and then a significant decrease. Furthermore, the optimal interfacial bonding strength (11.4 kN/m) and an excellent grinding performance (abrasive ratio of 23.2) were obtained from the diamond-steel matrix composites containing 10 vol% binder and 25% concentration of diamonds, when sintered at the temperature of 900 °C for holding time of 30 min and cold rolled at the reduction rate of 70%. The composites prepared with the optimum technical parameters had acceptable surface smoothness. In addition, the diamonds could be dispersed homogeneously in the matrices and firmly adhered to the substrates. When the diamond concentration was 25% in cold-rolling, the diamond-steel matrix composites showed better grinding performance. By improving the pressure condition of metallurgical bonding between diamonds and metal matrices from static pressure to rolling dynamic pressure, the sintering condition of temperature and holding time can be reduced and shortened, and the sintering condition effect on the interfacial bonding can be weaken. Thus, the application of the roll-bonding technique to the preparation of diamond-metal matrix composites could effectively avoid the thermal damage of diamonds caused by sintering process.

Similar content being viewed by others

References

Henriques B, Ferreira P, Buciumeanu M, Fredel M, Cabral A, Silva F, Miranda G (2017) Copper–nickel-based diamond cutting tools: stone cutting evaluation. Int J Adv Manuf Technol 92:1339–1348. https://doi.org/10.1007/s00170-017-0220-6

Costa MM, Flores P, Pereira D, Buciumeanu M, Cabral A, Fredel M, Silva FS, Henriques B, Miranda G (2018) Nickel-cobalt-based materials for diamond cutting tools. Int J Adv Manuf Technol 95:1059–1067. https://doi.org/10.1007/s00170-017-1226-9

Kang QP, He XB, Ren SB, Liu TT, Liu Q, Wu M, Qu XH (2015) Microstructure and thermal properties of copper-diamond composites with tungsten carbide coating on diamond particles. Mater Charact 105:18–23. https://doi.org/10.1016/j.matchar.2014.07.025

Sajjadnejad M, Omidvar H, Javanbakht M, Mozafari A (2017) Textural and structural evolution of pulse electrodeposited Ni/diamond nanocomposite coatings. J Alloys Compd 704:809–817. https://doi.org/10.1016/j.jallcom.2016.12.318

Mukhopadhyay P, Ghosh A (2018) Development and quality assessment of multi-point brazed diamond dressers produced by active brazing under high vacuum. Int J Adv Manuf Technol 99(1-4):647–662. https://doi.org/10.1007/s00170-018-2419-6

Grzonka J, Kruszewski MJ, Rosiński M, Ciupiński Ł, Michalski A, Kurzydłowski KJ (2015) Interfacial microstructure of diamond-copper matrix composites fabricated via a powder metallurgical route. Mater Charact 99:188–194. https://doi.org/10.1016/j.matchar.2014.11.032

Tillmann W, Ferreira M, Steffen A, Rüster K, Möller J, Bieder S, Paulus M, Tolan M (2013) Carbon reactivity of binder metals in diamond–metal composites – characterization by scanning electron microscopy and X-ray diffraction. Diam Relat Mater 38:118–123. https://doi.org/10.1016/j.diamond.2013.07.002

Tan ZQ, Li ZQ, Fan GL, Kai XY, Ji G, Zhang LT, Zhang D (2013) Diamond/aluminum composites processed by vacuum hot pressing: microstructure characteristics and thermal properties. Diam Relat Mater 31:1–5. https://doi.org/10.1016/j.diamond.2012.10.008

Das MK, Li RX, Qin JQ, Zhang XY, Das K, Thueploy A, Limpanart S, Boonyongmaneerat Y, Ma MZ, Liu RP (2017) Effect of electrodeposition conditions on structure and mechanical properties of Ni-W/diamond composite coatings. Surf Coat Technol 309:337–343. https://doi.org/10.1016/j.surfcoat.2016.11.074

Wang J, Zhang FL, Zhang T, Liu WG, Li WX, Zhou YM (2018) Preparation of Ni-P-diamond coatings with dry friction characteristics and abrasive wear resistance. Int J Refract Met Hard Mater 70:32–38. https://doi.org/10.1016/j.ijrmhm.2017.09.012

Lu JB, Cao ZY, Qi FJ, Qian M, Zhang WX (2018) Evolution of interface carbide diamond brazed with filler alloy containing Cr. Diam Relat Mater 90:116–125. https://doi.org/10.1016/j.diamond.2018.10.009

Bai H, Ma NG, Lang J, Zhu CX (2013) Effect of a new pretreatment on the microstructure and thermal conductivity of Cu/diamond composites. J Alloys Compd 580:382–385. https://doi.org/10.1016/j.jallcom.2013.06.027

Sidorenko DA, Zaitsev AA, Kirichenko AN, Levashov EA, Kurbatkina VV, Loginov PA, Rupasov SI, Andreev VA (2013) Interaction of diamond grains with nanosized alloying agents in metal–matrix composites as studied by Raman spectroscopy. Diam Relat Mater 38:59–62. https://doi.org/10.1016/j.diamond.2013.05.007

He ZH, Katsui H, Goto T (2016) High-hardness diamond composite consolidated by spark plasma sintering. J Am Ceram Soc 99(6):1862–1865. https://doi.org/10.1111/jace.14199

Chen Y, Fu YC, Su HH, Xu JH, Xu HJ (2014) The effects of solder alloys on the morphologies and mechanical properties of brazed diamond grits. Int J Refract Met Hard Mater 42:23–29. https://doi.org/10.1016/j.ijrmhm.2013.10.003

Qi WC, Lu JB, Li Y, Xu S, Zhong SJ, Wang BF, Qiu XK (2017) Vacuum brazing diamond grits with Cu-based or Ni-based filler metal. J Mater Eng Perform 26(8):4112–4120. https://doi.org/10.1007/s11665-017-2804-6

Ma BJ, Zhu HD (2015) Study on induction brazing of diamond grits coated by physical vapor deposition. Int J Adv Manuf Technol 80(1-4):599–605. https://doi.org/10.1007/s00170-015-7047-9

Hosseini Monazzah A, Bagheri R, Seyed Reihani SM, Pouraliakbar H (2015) Toughness enhancement in architecturally modified Al6061-5 vol.% SiCp laminated composites. Int J Damage Mech 24(2):245–262. https://doi.org/10.1177/1056789514529984

Hosseini Monazzah A, Pouraliakbar H, Jandaghi MR, Bagheri R, Seyed Reihani SM (2017) Influence of interfacial adhesion on the damage tolerance of Al6061/SiCp laminated composites. Ceram Int 43(2):2632–2643. https://doi.org/10.1016/j.ceramint.2016.11.074

Artini C, Muolo ML, Passerone A (2012) Diamond–metal interfaces in cutting tools: a review. J Mater Sci 47(7):3252–3264. https://doi.org/10.1007/s10853-011-6164-6

Pouraliakbar H, Hosseini Monazzah A, Bagheri R, Seyed Reihani SM, Khalaj G, Nazari A, Jandaghi MR (2014) Toughness prediction in functionally graded Al6061/SiCp composites produced by roll-bonding. Ceram Int 40(6):8809–8825. https://doi.org/10.1016/j.ceramint.2014.01.103

Hosseini Monazzah A, Pouraliakbar H, Bagheri R, Seyed Reihani SM (2014) Toughness behavior in roll-bonded laminates based on AA6061/SiCp composites. Mater Sci Eng 598(26):162–173. https://doi.org/10.1016/j.msea.2014.01.014

Vinogradov V, Knyazhansky M, Tsun A (2017) Effects of local overloads on cold rolling mill work rolls. Int J Mech Sci 123:106–116. https://doi.org/10.1016/j.ijmecsci.2017.01.046

Li BX, Chen ZJ, He WJ, Wang PJ, Lin JS, Wang Y, Peng L, Li J, Liu Q (2019) Effect of interlayer material and rolling temperature on microstructures and mechanical properties of titanium/steel clad plates. Mater Sci Eng A 749:241–248. https://doi.org/10.1016/j.msea.2019.02.018

Han Y, Zhang SH, Bai R, Zhou H, Su Z, Wu JJ, Wang JL (2020) Effect of nano-vanadium nitride on microstructure and properties of sintered Fe-Cu-based diamond composites. Int J Refract Met Hard Mater 91:105256. https://doi.org/10.1016/j.ijrmhm.2020.105256

Wang JS, Wan L, Chen J, Yan JW (2015) Anisotropy of synthetic diamond in catalytic etching using iron powder. Appl Surf Sci 346:388–393. https://doi.org/10.1016/j.apsusc.2015.04.022

Chen J, Wan L, Wang JS, Zhou XX, Zhang LX (2015) Effect of temperature on the catalytic etching behavior of synthetic diamond single crystals by iron powder. J Synth Cryst 44(6):1448–1453. https://doi.org/10.16553/j.cnki.issn1000-985x.2015.06.005\

De Oliveira LJ, Cabral SC, Filgueira M (2012) Study hot pressed Fe-diamond composites graphitization. Int J Refract Met Hard Mater 35:228–234. https://doi.org/10.1016/j.ijrmhm.2012.03.015

Li WS, Zhang J, Wang SC, Dong HF, Li YM, Liu Y (2012) Characterizations and mechanical properties of impregnated diamond segment using Cu-Fe-Co metal matrix. Rare Metals 31(1):81–87. https://doi.org/10.1007/s12598-012-0467-x

Konstanty JS, Tyrala D (2013) Wear mechanism of iron-base diamond-impregnated tool composites. Wear 303(1-2):533–540. https://doi.org/10.1016/j.wear.2013.04.016

Funding

This work was supported by the Youth Talent Support Program of Hebei Province of China (Grant number: 2016009 to Q. Z.) and the Youth Talent Support Program of Danfeng City of Jiangsu Province of China (Grant number: 2019003 to Q. Z.)

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, Wd., Li, Yg., Zou, Q. et al. Morphology and properties of diamond-copper/steel matrix abrasive composites prepared by roll-bonding technique. Int J Adv Manuf Technol 112, 705–717 (2021). https://doi.org/10.1007/s00170-020-05911-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05911-9