Abstract

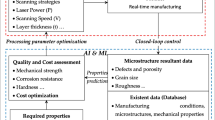

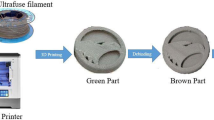

The most prevalent hybrid additive manufacturing (HAM) method in the industry involves the combination of conventional processes, such as hot isostatic pressing or forging. In this way, a part is printed to its near-net-shape by additive manufacturing and then finished using open forge (Ampliforge). Hereby, the performance of the printed part will be improved by the downstream processes; this method also affords a reduction in time, cost, and waste material. In this study, the AISI 316L stainless steel parts were produced through selective laser melting (SLM) process and the cellular structure with columnar grains appeared. Then, hot compression experimental works were performed to investigate flow behavior, hot workability, density, and microstructure evolutions during the process. This process resulted in a near fully-dense part with a homogeneous microstructure without anisotropy of properties and higher hot deformation activation energy and peak stress in comparison with similar conventionally manufactured stainless steel.

Similar content being viewed by others

References

Cheng B, Shrestha S, Chou K (2016) Stress and deformation evaluations of scanning strategy effect in selective laser melting. Addit Manuf 12:240–251. https://doi.org/10.1016/J.ADDMA.2016.05.007

Bartolomeu F, Buciumeanu M, Pinto E, Alves N, Carvalho O, Silva FS, Miranda G (2017) 316L stainless steel mechanical and tribological behavior—a comparison between selective laser melting, hot pressing and conventional casting. Addit Manuf 16:81–89. https://doi.org/10.1016/J.ADDMA.2017.05.007

Frazier WE (2014) Metal additive manufacturing: a review. J Mater Eng Perform 23:1917–1928. https://doi.org/10.1007/s11665-014-0958-z

Huang SH, Liu P, Mokasdar A, Hou L (2013) Additive manufacturing and its societal impact: a literature review. Int J Adv Manuf Technol 67:1191–1203. https://doi.org/10.1007/s00170-012-4558-5

Herzog D, Seyda V, Wycisk E, Emmelmann C (2016) Additive manufacturing of metals. Acta Mater 117:371–392. https://doi.org/10.1016/J.ACTAMAT.2016.07.019

Bambach M, Sizova I (2018) Hot working behavior of selective laser melted and laser metal deposited Inconel 718. AIP Conf Proc 1960:170001. https://doi.org/10.1063/1.5035058

Qiu C, Adkins NJE, Attallah MM (2013) Microstructure and tensile properties of selectively laser-melted and of HIPed laser-melted Ti–6Al–4V. Mater Sci Eng A 578:230–239. https://doi.org/10.1016/J.MSEA.2013.04.099

Kunze K, Etter T, Grässlin J, Shklover V (2015) Texture, anisotropy in microstructure and mechanical properties of IN738LC alloy processed by selective laser melting (SLM). Mater Sci Eng A 620:213–222. https://doi.org/10.1016/J.MSEA.2014.10.003

Springer Fachmedien Wiesbaden (2018) Competition among materials will always spawn innovations. Light Des Worldw 11:22–25. https://doi.org/10.1007/s41777-018-0031-y

Kamal M, Rizza G (2019) Design for metal additive manufacturing for aerospace applications. Addit Manuf Aerosp Ind:67–86. https://doi.org/10.1016/B978-0-12-814062-8.00005-4

Alcoa Opens 3D-Printing Metal Powder Plant | 2016-07-22 | Forge Magazine n.d. https://www.forgemag.com/articles/84506-alcoa-opens-3d-printing-metal-powder-plant. Accessed February 1, 2020

Alcoa—the Element of Possibility™ n.d. https://www.alcoa.com/global/en/home.asp. Accessed February 1, 2020

Tao P, Zhong J, Li H, Hu Q, Gong S, Xu Q (2019) Microstructure, mechanical properties, and constitutive models for Ti–6Al–4V alloy fabricated by selective laser melting (SLM). Metals (Basel) 9. https://doi.org/10.3390/met9040447

Abedi HR, Hanzaki AZ, Azami M, Kahnooji M, Rahmatabadi D (2019) The high temperature flow behavior of additively manufactured Inconel 625 superalloy. Mater Res Express 6:116514. https://doi.org/10.1088/2053-1591/ab44f6

Mostafa A, Shahriari D, Rubio IP, Brailovski V, Jahazi M, Medraj M (2018) Hot compression behavior and microstructure of selectively laser-melted IN718 alloy. Int J Adv Manuf Technol 96:371–385. https://doi.org/10.1007/s00170-017-1522-4

Sizova I, Bambach M (2018) Hot workability and microstructure evolution of pre-forms for forgings produced by additive manufacturing. J Mater Process Technol 256:154–159. https://doi.org/10.1016/J.JMATPROTEC.2018.02.017

Bambach M, Sizova I, Emdadi A (2019) Development of a processing route for Ti-6Al-4V forgings based on preforms made by selective laser melting. J Manuf Process 37:150–158. https://doi.org/10.1016/j.jmapro.2018.11.011

AlMangour B, Kim Y-K, Grzesiak D, Lee K-A (2019) Novel TiB2-reinforced 316L stainless steel nanocomposites with excellent room- and high-temperature yield strength developed by additive manufacturing. Compos B Eng 156:51–63. https://doi.org/10.1016/J.COMPOSITESB.2018.07.050

Aboulkhair NT, Everitt NM, Ashcroft I, Tuck C (2014) Reducing porosity in AlSi10Mg parts processed by selective laser melting. Addit Manuf 1–4:77–86. https://doi.org/10.1016/J.ADDMA.2014.08.001

Yap CY, Chua CK, Dong ZL, Liu ZH, Zhang DQ, Loh LE, Sing SL (2015) Review of selective laser melting: materials and applications. Appl Phys Rev 2:41101. https://doi.org/10.1063/1.4935926

Montero-Sistiaga ML, Godino-Martinez M, Boschmans K, Kruth J-P, Van Humbeeck J, Vanmeensel K (2018) Microstructure evolution of 316L produced by HP-SLM (high power selective laser melting). Addit Manuf 23:402–410. https://doi.org/10.1016/J.ADDMA.2018.08.028

Gu D, Hagedorn Y-C, Meiners W, Meng G, Batista RJS, Wissenbach K, Poprawe R (2012) Densification behavior, microstructure evolution, and wear performance of selective laser melting processed commercially pure titanium. Acta Mater 60:3849–3860. https://doi.org/10.1016/J.ACTAMAT.2012.04.006

Verhaeghe F, Craeghs T, Heulens J, Pandelaers L (2009) A pragmatic model for selective laser melting with evaporation. Acta Mater 57:6006–6012. https://doi.org/10.1016/J.ACTAMAT.2009.08.027

Salman OO, Gammer C, Chaubey AK, Eckert J, Scudino S (2019) Effect of heat treatment on microstructure and mechanical properties of 316L steel synthesized by selective laser melting. Mater Sci Eng A 748:205–212. https://doi.org/10.1016/J.MSEA.2019.01.110

Faini F, Attanasio A, Ceretti E (2018) Experimental and FE analysis of void closure in hot rolling of stainless steel. J Mater Process Technol 259:235–242. https://doi.org/10.1016/j.jmatprotec.2018.04.033

Huang K, Logé RE (2016) A review of dynamic recrystallization phenomena in metallic materials. Mater Des 111:548–574. https://doi.org/10.1016/J.MATDES.2016.09.012

Li N, Zhao C, Jiang Z, Zhang H (2019) Flow behavior and processing maps of high-strength low-alloy steel during hot compression. Mater Charact 153:224–233. https://doi.org/10.1016/J.MATCHAR.2019.05.009

Chamanfar A, Alamoudi MT, Nanninga NE, Misiolek WZ (2019) Analysis of flow stress and microstructure during hot compression of 6099 aluminum alloy (AA6099). Mater Sci Eng A 743:684–696. https://doi.org/10.1016/J.MSEA.2018.11.076

Guo MW, Wang ZH, Zhou ZA, Sun SH, Fu WT (2015) Effect of nitrogen content on hot deformation behavior and grain growth in nuclear grade 316LN stainless steel. Adv Mater Sci Eng 2015:1–8. https://doi.org/10.1155/2015/427945

Samantaray D, Mandal S, Kumar V, Albert SK, Bhaduri AK, Jayakumar T (2012) Optimization of processing parameters based on high temperature flow behavior and microstructural evolution of a nitrogen enhanced 316L(N) stainless steel. Mater Sci Eng A 552:236–244. https://doi.org/10.1016/J.MSEA.2012.05.036

Ji G, Li F, Li Q, Li H, Li Z (2011) A comparative study on Arrhenius-type constitutive model and artificial neural network model to predict high-temperature deformation behaviour in Aermet100 steel. Mater Sci Eng A 528:4774–4782. https://doi.org/10.1016/J.MSEA.2011.03.017

Ghazani MS, Eghbali B (2018) Characterization of the hot deformation microstructure of AISI 321 austenitic stainless steel. Mater Sci Eng A 730:380–390. https://doi.org/10.1016/J.MSEA.2018.06.025

Huang X, Zhang H, Han Y, Wu W, Chen J (2010) Hot deformation behavior of 2026 aluminum alloy during compression at elevated temperature. Mater Sci Eng A 527:485–490. https://doi.org/10.1016/J.MSEA.2009.09.042

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Habibiyan, A., Hanzaki, A.Z. & Abedi, H.R. An investigation into microstructure and high-temperature mechanical properties of selective laser-melted 316L stainless steel toward the development of hybrid Ampliforge process. Int J Adv Manuf Technol 110, 383–394 (2020). https://doi.org/10.1007/s00170-020-05870-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05870-1