Abstract

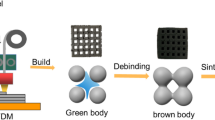

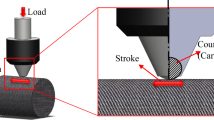

The selective laser melting (SLM) process is of great interest for fabrication of metal parts, and a number of studies have been conducted to provide in-depth understanding of how stainless steel 316L parts can be fabricated using this powder-bed-fusion-based additive manufacturing (AM) process. In comparison with SLM stainless steel 316L, this paper introduces an innovative AM process for making austenitic stainless steel 316L parts using a metal–polymer composite filament (Ultrafuse 316LX). Stainless steel 316L metal specimens were printed using a material extrusion (FDM)-based three-dimensional (3D) printer loaded with Ultrafuse filament, followed by an industry-standard debinding and sintering process. Tests were performed to understand the material properties, such as hardness, tensile strength, and microstructural characteristics. Part shrinkage was also analyzed based on the features of the FDM stainless steel 316L component. A preliminary guideline on how to select among these two alternative AM processes for fabrication of metal parts is discussed.

Similar content being viewed by others

References

J.J. Lewandowski and M. Seifi, Annu. Rev. Mater. Res. 46, 151 (2016).

I. Gibson, D.W. Rosen, and B. Stucker, Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing (Berlin: Springer, 2009).

D.S. Thomas and S.W. Gilbert, NIST Spec. Publ. (2014). https://doi.org/10.6028/NIST.SP.1176.

D. Kong, X. Ni, C. Dong, X. Lei, L. Zhang, C. Man, J. Yao, X. Cheng, and X. Li, Mater. Des. 152, 88 (2018).

E. Liverani, S. Toschi, L. Ceschini, and A. Fortunato, J. Mater. Process. Technol. 249, 255 (2017).

Z. Sun, X. Tan, S.B. Tor, and W.Y. Yeong, Mater. Des. 104, 197 (2016).

F. Bartolomeu, M. Buciumeanu, E. Pinto, N. Alves, O. Carvalho, F.S. Silva, and G. Miranda, Addit. Manuf. 16, 81 (2017).

M. Ma, Z. Wang, and X. Zeng, Mater. Sci. Eng. A 685, 265 (2017).

J. Suryawanshi, K.G. Prashanth, and U. Ramamurty, Mater. Sci. Eng. A 696, 113 (2017).

D. Kong, X. Ni, C. Dong, L. Zhang, C. Man, J. Yao, K. Xiao, and X. Li, Electrochim. Acta 276, 293 (2018).

A. Páez-Pavón, A. Jiménez-Morales, T.G. Santos, L. Quintino, and J.M. Torralba, J. Magn. Magn. Mater. 416, 342 (2016).

S. Afazov, W. Denmark, B.L. Toralles, A. Holloway, and A. Yaghi, Addit. Manuf. 17, 15 (2017).

Y. Liu, Y. Yang, and D. Wang, Int. J. Adv. Manuf. Technol. 90, 2913 (2017).

Acknowledgement

The authors acknowledge Dr. Shanshan Zhang and the staff of the Rapid Prototyping Center at the University of Louisville for help with material property testing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gong, H., Snelling, D., Kardel, K. et al. Comparison of Stainless Steel 316L Parts Made by FDM- and SLM-Based Additive Manufacturing Processes. JOM 71, 880–885 (2019). https://doi.org/10.1007/s11837-018-3207-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3207-3