Abstract

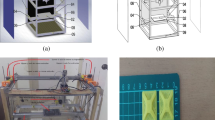

Additive manufacturing (AM) is an important, rapidly emerging, manufacturing technology that takes the information from a computer-aided design (CAD) and builds parts in a layer-by-layer style. Thus, since the development of 3D printing, the fused deposition modeling (FDM) is one of the most promising and inexpensive techniques for shaping free-form parts. It used a thermoplastic filament as a starting material to extrude, layer by layer, the suitable 3D object. It is assisted by a large community of developers, searchers, and users and with multiple free hardware and software open sources expanding the scope of its applications. However, in this process, printing objects with multi-materials and multicolors becomes a major challenge for most extrusion system of printing platforms. For example, in case it is required to print multi-material and multicolored parts, a high-quality head extruder should be used. The main objective of this work is to show the importance of proposing a new extruder system of printing parts with multicolors and materials. For this purpose, in the present paper, the different extrusion systems capable of printing parts with multicolors and materials were presented. The operating principle of each extrusion system is well explained through functional diagrams. Then, its advantages and disadvantages are cited. Finally, some prospects for improving these systems are presented and that will be the work of the next paper.

Similar content being viewed by others

References

Singh R, Kumar R, Ranjan N (2019) Sustainability of recycled ABS and PA6 by banana fiber reinforcement: thermal, mechanical and morphological properties. J Inst Eng India Ser 100(2):351–360

Boulaala M, Elmessaoudi D, Buj-Corral I, El Mesbahi J, Mazighe M, Astito A, El Mrabet M, Elmesbahi A (2019) Reviews of mechanical design and electronic control of multi-material/color FDM 3D printing, International Conference on Integrated Design and Production, CPI’2019 11 th Edition, Fez, Morocco, 14 - 16Octobe

Ali MH, Mir-Nasiri N, Ko WL (2016) Multi-nozzle extrusion system for 3D printer and its control mechanism. Int J Adv Manuf Technol 86:1–4

Laureto JJ, Pearce JM (2017) Open source multi-head 3D printer for polymer-metal composite component manufacturing, MDPI. Technologies 5(36):1–22

Paritosh Santosh M (2019) Process planning for concurrent multi-nozzle 3D printing, thesis https://scholarworks.rit.edu/theses/10075. Accessed 09 Jan 2020

Löffler R, Koch M (2019) Innovative extruder concept for fast and efficient additive manufacturing, IFAC 52 (10):242–247, paper online at https://www.sciencedirect.com/science/article/pii/S2405896319309267. Accessed 09 Jan 2020

E3D (2019) Online Kraken E3D Online. Available at: https://e3d-online.com/kraken. Accessed 09 Jan 2020

Keller P (2016) Designing a compact dual head for flm 3d printing technology, MM Sci J, pp 1560-1564

Guide on how to choose a professional desktop 3d printer. https://www.bcn3dtechnologies.com/documents. Accessed 09 Jan 2020

Buj-Corral I,Domínguez-Fernández A, Durán-Llucià R (2019) Influence of print orientation on surface roughness in fused deposition modeling (FDM) Processes, Materials, 12 (23), 3834, paper online at https://doi.org/10.3390/ma12233834. Accessed 23 Jan 2020

Miller R Autodesk looks to future of 3D printing with Project Escher, Retrieved from https://techcrunch.com/2016/04/10/autodesk-looks-to-future-of-3d-printing-with-project-escher. Accessed 09 Jan 2020

Stratasys, Inc.(2007) Single-motor extrusion head having multiple extrusion lines. USA. International publication number WO 2007/130229 A2. Publication Date -11-15

Andersen KE(2015) Optimization of a low-melting alloy for fused filament fabrication, Thesis, SIMON FRASER UNIVERSITY Summer

https://3dprintingindustry.com/news/spiderbot-aiming-extrude-perfect-double-filament-webs-32626/, last accessed 09/01/2020.

Prusa J (2019) Prusa I3 MK3S multi-material f upgrade 2.0 addon, https://www.prusa3d.com/original-prusa-i3-mk3, last accessed 09 Jan 2020

Lina W, Shena H, Xua G, Zhanga L, Fua J, Dengc X (2018) Single-layer temperature-adjusting transition method to improve the bond strength of 3D-printed PCL/PLA parts. Compos Part A 115:22–30

E3D (2019) tool-changer and motion system: beta 30, https://e3d-online.com/blog/2019/04/18/toolchanger-the-update-youve-all-been-waiting-for. Accessed 21 August 2019

Mark2 (2017) The smart way to multi-extrusion, https://magnetic-tool-changer.com. Accessed 21 Aug 2019.

Simple, multi-material 3D printing, Palette 2, https://www.mosaicmfg.com. Accessed 21 August 2019

Pascale D, Simion I (2018) Multi-material 3d printer extruder concept. J Ind Des Eng Graph 13(28):25

Guan Y, Shen B, Yu Z, Zi’ang F (2017) Design of color mixing 3D printing system based on LabVIEW. J Comput 28(6):277–287

The crane quad 3d printer, within color-calibrated CMYK filaments, https://store.printm3d.com/products/the-crane-quad-3d-printer?variant=21155064053838. Accessed 09 Jan 2020

ORD Solutions (2019) RoVa3D 5 extruder 3D printer package, https://www.ordsolutions.com/rova3d-5-extruder-3d-printer-package. Accessed 09 Jan 2020

Search keyword: Ramps, Rambo, Rumba...etc., https://reprap.org/wiki/. Accessed 21 Aug 2019

https://reprap.org/wiki/Comparison_of_Electronics, last accessed 09 Jan 2020

Berbesi J, MartheynSaumeth K, Pinilla F (2017) Parallel control firmware for CNC milling machine based in Arduino, Proceedings of Technical Papers - International Microsystems, Packaging, Assembly, and Circuits Technology Conference, IMPACT, 2017-Octob, pp 319-322

Raj JJR, Rahman SMK, SnehAnand (2016) 8051 microcontrollers to FPGA and ADC interface design for high speed parallel processing systems – application in ultrasound scanners. Eng Sci Technol Int J 19(3):1416–1423

de la Piedra A, Braeken A, AbdellahTouhafi (2012) Sensor systems based on FPGAs and their applications: a survey. Sensors (Switzerland) 12(9):12235–12264

Strøm T, Schoeberl M (2012) A desktop 3D printer in safety-critical java, ACM International Conference Proceeding Series, pp 72-79

Younes D, Yuegang T, Xin C, Alghannam E, Altazah A (2018) Design of control system for 3D printer based On DSP and FPGA, J Autom Control Eng Vol. 6, No. 1, June 2018, doi: https://doi.org/10.18178/joace.6.1.40-46

Chen W, Wen Z, Xu Z, Liu J (2008) Implementation of 3-axis linear interpolation in a FPGA-based 4-axis motion controller, 3rd IEEE Conference on Industrial Electronics and Applications pp 308–1313. https://doi.org/10.1109/ICIEA.2008.4582729

Quang NK, Kung Y-S, Ha QP (2011) FPGA-based control architecture integration for multiple-axis tracking motion systems, IEEE/SICE International Symposium on System Integration (SII) pp 591–596. https://doi.org/10.1109/SII.2011.6147515

Erkol HO, Demirel H (2016) Design and implementation of an 18-dof six-legged robot: ABR1, Int J Adv Res Comput Eng Technol 5(6)

Pei E, Monzón M, Bernard A (2019) Additive manufacturing developments in training and education, Springer International Publishing AG, part of Springer Nature. https://doi.org/10.1007/978-3-319-76084-1

Saari M, Cox B, Richer E, Krueger PS, Cohen AL (2017) Fiber encapsulation additive manufacturing: an enabling technology for 3D printing of electromechanical devices and robotic components. 3D Printing Additive Manufacturing 4(2):116–119

Zapciu A, Constantin G, Popescu D (2015) Elastomer overmolding over rigid 3d-printed parts for rapid prototypes. Proc Manuf Syst 13(2):75–80

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Boulaala, M., Elmessaoudi, D., Buj-Corral, I. et al. Towards design of mechanical part and electronic control of multi-material/multicolor fused deposition modeling 3D printing. Int J Adv Manuf Technol 110, 45–55 (2020). https://doi.org/10.1007/s00170-020-05847-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05847-0