Abstract

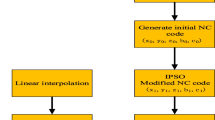

The evaluation of the results of geometric error compensation is critical, and it can serve as the feedback of the compensation to help improve the precision of the compensation. In this paper, the closed-loop mode geometric error compensation of five-axis machine tools is presented by correcting the movements of all axes. At first, general geometric error modeling of the machine tool is proposed based on POE theory. The initial positions of linear axes and rotary axes relative to the machine tool are considered and the error twist of each axis containing position-independent errors is established. Second, the closed-loop mode is developed by analyzing the open-loop mode of geometric error compensation. The precision inverse feedback module is formed by introducing the designed tool poses. The output of the feedback is the integrated errors of the revised movements of axes relative to the ideal tool poses of nominal movements of axes. Third, the adaptive correction of movements of axes is proposed based on CSO (chicken swarm optimization). The initializing of the swarm, the Jacobian based moving of roosters, and the moving of chicks containing one mutation are developed. The fitness of the swarm is calculated using the integrated errors relative to the compensation goal in the precision inverse feedback. Finally, simulations by comparing with open-loop mode error compensation and real cutting experiments are proposed on one SmartCNC500_DRTD five-axis machine center to verify the effectiveness of the closed-loop mode geometric error compensation.

Similar content being viewed by others

References

Shen H, Fu J, He Y, Yao X (2012) On-line asynchronous compensation methods for static/quasi-static error implemented on CNC machine tools. Int J Mach Tools Manuf 60(0):14–26

Khan AW, Wuyi C (2010) Systematic geometric error modeling for workspace volumetric calibration of a 5-axis turbine blade grinding machine. Chin J Aeronaut 23(5):604–615

Wu C, Fan J, Wang Q, Pan R, Tang Y, Li Z (2018) Prediction and compensation of geometric error for translational axes in multi-axis machine tools. Int J Adv Manuf Technol 95(9):3413–3435

Li J, Mei B, Shuai C, X-j L, Liu D (2019) A volumetric positioning error compensation method for five-axis machine tools. Int J Adv Manuf Technol 103(9):3979–3989

Yuen A, Altintas Y (2018) Geometric error compensation with a six degree-of–freedom rotary magnetic actuator. J Manuf Sci Eng 140(11):111016-111016-10

Li Z, Yang J, Fan K, Zhang Y (2015) Integrated geometric and thermal error modeling and compensation for vertical machining centers. Int J Adv Manuf Technol 76(5–8):1139–1150

Cheng Q, Dong L, Liu Z, Li J, Gu P (2018) A new geometric error budget method of multi-axis machine tool based on improved value analysis. Proc Inst Mech Eng C J Mech Eng Sci 0(0):095440621774926

Cai L, Zhang Z, Cheng Q, Liu Z, Gu P, Qi Y (2016) An approach to optimize the machining accuracy retainability of multi-axis NC machine tool based on robust design. Precis Eng 43:370–386

Fu G, Fu J, Xu Y, Chen Z (2014) Product of exponential model for geometric error integration of multi-axis machine tools. Int J Adv Manuf Technol 71(9–12):1653–1667

Fu G, Fu J, Shen H, Xu Y, Ya J (2015) Product-of-exponential formulas for precision enhancement of five-axis machine tools via geometric error modeling and compensation. Int J Adv Manuf Technol 81(1–4):289–305

Yang J, Mayer JRR, Altintas Y (2015) A position independent geometric errors identification and correction method for five-axis serial machines based on screw theory. Int J Mach Tools Manuf 95:52–66

Xiang S, Li H, Deng M, Yang J (2018) Geometric error analysis and compensation for multi-axis spiral bevel gears milling machine. Mech Mach Theory 121(Supplement C):59–74

Liu Y, Wan M, Xing W-J, Xiao Q-B, Zhang W-H (2018) Generalized actual inverse kinematic model for compensating geometric errors in five-axis machine tools. Int J Mech Sci 145:299–317

Liu Y, Wan M, Xiao Q-B, Zhang W-H (2019) Identification and compensation of geometric errors of rotary axes in five-axis machine tools through constructing equivalent rotary axis (ERA). Int J Mech Sci 152:211–227

Zhong X, Liu H, Mao X, Li B, He S (2019) Influence and error transfer in assembly process of geometric errors of a translational axis on volumetric error in machine tools. Measurement 140:450–461

Cheng Q, Sun BW, Liu ZF, Li JY, Dong XM, Gu PH (2017) Key geometric error extraction of machine tool based on extended Fourier amplitude sensitivity test method. Int J Adv Manuf Technol 90(9–12):3369–3385

Chen J, Lin S, He B (2014) Geometric error compensation for multi-axis CNC machines based on differential transformation. Int J Adv Manuf Technol 71(1–4):635–642

J-x C, Lin S-w, X-l Z (2016) A comprehensive error analysis method for the geometric error of multi-axis machine tool. Int J Mach Tools Manuf 106:56–66

Tang H, Duan J-A, Lan S, Shui H (2015) A new geometric error modeling approach for multi-axis system based on stream of variation theory. Int J Mach Tools Manuf 92(0):41–51

Fu GQ, Fu JZ, Xu YT, Chen ZC, Lai JT (2015) Accuracy enhancement of five-axis machine tool based on differential motion matrix: geometric error modeling, identification and compensation. Int J Mach Tool Manu 89(0):170–181

Fu G, Gong H, Fu J, Gao H, Deng X (2019) Geometric error contribution modeling and sensitivity evaluating for each axis of five-axis machine tools based on POE theory and transforming differential changes between coordinate frames. Int J Mach Tools Manuf 147:103455

Yang J, Ding H (2016) A new position independent geometric errors identification model of five-axis serial machine tools based on differential motion matrices. Int J Mach Tools Manuf 104:68–77

Uddin MS, Ibaraki S, Matsubara A, Matsushita T (2009) Prediction and compensation of machining geometric errors of five-axis machining centers with kinematic errors. Precis Eng J Int Soc Precis Eng Nanotechnol 33(2):194–201

Ding S, Huang X, Yu C, Wang W (2016) Actual inverse kinematics for position-independent and position-dependent geometric error compensation of five-axis machine tools. Int J Mach Tools Manuf 111:55–62

Zhou X, Jiang Z, Song B, Tang X, Zheng S (2017) A compensation method for the geometric errors of five-axis machine tools based on the topology relation between axes. Int J Adv Manuf Technol 88(5–8):1993–2007

Gao W, Weng L, Zhang J, Tian W, Zhang G, Zheng Y, Li J (2020) An improved machine tool volumetric error compensation method based on linear and squareness error correction method. Int J Adv Manuf Technol 106(11):4731–4744

Xiang S, Altintas Y (2016) Modeling and compensation of volumetric errors for five-axis machine tools. Int J Mach Tools Manuf 101:65–78

Zhu S, Ding G, Qin S, Lei J, Zhuang L, Yan K (2012) Integrated geometric error modeling, identification and compensation of CNC machine tools. Int J Mach Tools Manuf 52(1):24–29

Peng FY, Ma JY, Wang W, Duan XY, Sun PP, Yan R (2013) Total differential methods based universal post processing algorithm considering geometric error for multi-axis NC machine tool. Int J Mach Tools Manuf 70(0):53–62

Wu C, Fan J, Wang Q, Chen D (2018) Machining accuracy improvement of non-orthogonal five-axis machine tools by a new iterative compensation methodology based on the relative motion constraint equation. Int J Mach Tools Manuf 124:80–98

Lei WT, Hsu YY (2003) Accuracy enhancement of five-axis CNC machines through real-time error compensation. Int J Mach Tools Manuf 43(9):871–877

Givi M, Mayer JRR (2015) Volumetric error formulation and mismatch test for five-axis CNC machine compensation using differential kinematics and ephemeral G-code. Int J Adv Manuf Technol 77(9–12):1645–1653

Fu G, Fu J, Shen H, Sha J, Xu Y (2016) Numerical solution of simultaneous equations based geometric error compensation for CNC machine tools with workpiece model reconstruction. Int J Adv Manuf Technol 86(5):2265–2278

Lei WT, Sung MP (2008) NURBS-based fast geometric error compensation for CNC machine tools. Int J Mach Tools Manuf 48(3–4):307–319

Fu G, Gong H, Gao H, Gu T, Cao Z (2019) Integrated thermal error modeling of machine tool spindle using a chicken swarm optimization algorithm-based radial basic function neural network. Int J Adv Manuf Technol

Fu G, Fu J, Shen H, Yao X, Chen Z (2015) NC codes optimization for geometric error compensation of five-axis machine tools with one novel mathematical model. Int J Adv Manuf Technol 80(9–12):1879–1894

Fu G, Zhang L, Fu J, Gao H, Ya J (2018) F test-based automatic modeling of single geometric error component for error compensation of five-axis machine tools. Int J Adv Manuf Technol 94(9–12):4493–4505

Lin ZW, Fu JZ, Sun YF, Gao Q, Xu GH, Wang ZT (2017) Non-retraction toolpath generation for irregular compound freeform surfaces with the LKH TSP solver. Int J Adv Manuf Technol 92(5–8):2325–2339

Funding

This work was financially supported by the National Natural Science Foundation of China (No. 51805457), Sichuan Science and Technology Program (2019YJ0249), China Postdoctoral Science Foundation (2020M673211), Key Science and Technology Project of Sichuan Province (2020ZDZX0003), the National Natural Science Foundation of China (No. 51775452), and the Fundamental Research Funds for the Central Universities (2682019CX30).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

POE theory

The twist and the twist coordinates are represented as:

where v = [v1, v2, v3]T represents translational velocity,\( \hat{\upomega} \) is a skew-symmetric matrix and vector ω = [ω1, ω2, ω3]T represents the rotational velocity. The exponential matrix of the twist is represented as [9]

When ‖ω‖ ≠ 0,\( \uptheta =\sqrt{\upomega_1^2+{\upomega}_2^2+{\upomega}_3^2} \) represents the rotation angle. And when ‖ω‖ = 0,\( \uptheta =\sqrt{v_1^2+{v}_2^2+{v}_3^2} \), represents the translational distance. \( {e}^{\hat{\upomega}\uptheta} \) can be obtained by the means of triangular progression as

The POE formula of the forward kinematics of an open chain robot is as [9]:

The twist and the exponential matrix of position-dependent errors

The twist of position-dependent errors can be expressed as the unit twist and the motion angle as

Then, the corresponding exponential matrix can be calculated based on POE theory as

Where m, lx, ly, and lz are shown as

Due to the small angle of angular errors, sin m = m and cos m = 1 according to the small-angle approximation. Then, the exponential matrix of the error twist can be expressed as

Rights and permissions

About this article

Cite this article

Fu, G., Shi, J., Xie, Y. et al. Closed-loop mode geometric error compensation of five-axis machine tools based on the correction of axes movements. Int J Adv Manuf Technol 110, 365–382 (2020). https://doi.org/10.1007/s00170-020-05793-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05793-x