Abstract

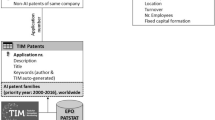

Digital twin (DT) can facilitate interaction between the physical and the cyber worlds and achieve smart manufacturing. However, the DT’s development in the industry remains vague. This study investigates the global patent databases of DT patents and summarizes related technologies, effects, and applications. Patent map analysis is used to uncover the patent development trajectory of DT in the patent databases of the USA, China, and the World Intellectual Property Organization among European nations. In addition, a nation-based survey is conducted to explore their DT patent trends. Findings reveal that DT fails to form a comprehensively connected technology, which is a typical phenomenon for a technology that remains in its early stage of development. In the present study, the two-dimensional matrix analysis of patent technology and effect exhibits that several patents created a variety of effects and reached saturation. Moreover, several technology–effect domains remain, and DT-related technology gaps exist in a number of potential effects. The DT-related patents are distributed unevenly in various industries. For instance, most of the DT-related patents appear in the manufacturing industry. Furthermore, our K-mode cluster analysis reveals that the DT-related patents are distributed in five subgroups of the three dimensions, namely, technology, effect, and application.

Similar content being viewed by others

References

Rosen R, Von Wichert G, Lo G, Bettenhausen KD (2015) About the importance of autonomy and digital twins for the future of manufacturing. IFAC-PapersOnLine 48(3):567–572

Qu T, Lei S, Wang Z, Nie D, Chen X, Huang GQ (2016) IoT-based real-time production logistics synchronization system under smart cloud manufacturing. Int J Adv Manuf Technol 84(1–4):147–164

Debroy T, Zhang W, Turner J, Babu SS (2017) Building digital twins of 3D printing machines. Scr Mater 135:119–124

Coronado PDU, Lynn R, Louhichi W, Parto M, Wescoat E, Kurfess T (2018) Part data integration in the shop floor digital twin: mobile and cloud technologies to enable a manufacturing execution system. J Manuf Syst 48:25–33

Tao F, Cheng J, Qi Q, Zhang M, Zhang H, Sui F (2018) Digital twin-driven product design, manufacturing and service with big data. Int J Adv Manuf Technol 94(9–12):3563–3576

Tuegel EJ, Ingraffea AR, Eason TG, Spottswood SM (2011) Reengineering aircraft structural life prediction using a digital twin. Int J Aerospace Eng 2011

Grieves M, Vickers J (2017) Digital twin: mitigating unpredictable, undesirable emergent behavior in complex systems. In: Transdisciplinary perspectives on complex systems. Springer:85–113

Negri E, Fumagalli L, Macchi M (2017) A review of the roles of digital twin in cps-based production systems. Procedia Manufacturing 11:939–948

Schleich B, Anwer N, Mathieu L, Wartzack S (2017) Shaping the digital twin for design and production engineering. CIRP Ann 66(1):141–144

Verner I, Cuperman D, Fang A, Reitman M, Romm T, Balikin G (2018) Robot online learning through digital twin experiments: a weightlifting project. In: Online engineering & internet of things. Springer, 307–314

Klumpp M, Hesenius M, Meyer O, Ruiner C, Gruhn V (2019) Production logistics and human-computer interaction—state-of-the-art, challenges and requirements for the future. Int J Adv Manuf Technol 105(9):3691–3709

Tao F, Zhang H, Liu A, Nee AY (2018) Digital twin in industry: state-of-the-art. IEEE Transactions on Industrial Informatics 15(4):2405–2415

Trappey AJ, Trappey CV, Govindarajan UH, Jhuang AC (2018) Construction and validation of an ontology-based technology function matrix: technology mining of cyber physical system patent portfolios. World Patent Inf 55:19–24

Moehrle MG, Caferoglu H (2019) Technological speciation as a source for emerging technologies. Using semantic patent analysis for the case of camera technology. Technol Forecast Soc Chang 146:776–784

Li X, Xie Q, Jiang J, Zhou Y, Huang L (2019) Identifying and monitoring the development trends of emerging technologies using patent analysis and twitter data mining: the case of perovskite solar cell technology. Technol Forecast Soc Chang 146:687–705

Kagermann H, Helbig J, Hellinger A, Wahlster W (2013) Recommendations for implementing the strategic initiative INDUSTRIE 4.0: securing the future of German manufacturing industry; final report of the Industrie 4.0 Working Group. Forschungsunion

Sung TK (2018) Industry 4.0: a Korea perspective. Technol Forecast Soc Chang 132:40–45

Veeramani D, Wang K-J (2006) Bid construction scheme for job flow time reduction in auction-based fully-distributed manufacturing systems. Int J Adv Manuf Technol 28(5–6):541–550

Chen JC, Cheng C-H, Huang PB, Wang K-J, Huang C-J, Ting T-C (2013) Warehouse management with lean and RFID application: a case study. Int J Adv Manuf Technol 69(1–4):531–542

Porter ME, Heppelmann JE (2014) How smart, connected products are transforming competition. Harv Bus Rev 92(11):64–88

Wang L, Törngren M, Onori M (2015) Current status and advancement of cyber-physical systems in manufacturing. J Manuf Syst 37:517–527

Wang S, Wan J, Li D, Zhang C (2016) Implementing smart factory of industrie 4.0: an outlook. International Journal of Distributed Sensor Networks 12(1):3159805

Hermann M, Pentek T, Otto B (2016) Design principles for industrie 4.0 scenarios. In: 2016 49th Hawaii international conference on system sciences (HICSS). IEEE: 3928-3937

Zhu Z, Liu C, Xu X (2019) Visualisation of the digital twin data in manufacturing by using augmented reality. Procedia CIRP 81:898–903

Kraft EM The air force digital thread/digital twin-life cycle integration and use of computational and experimental knowledge. In: 54th AIAA Aerospace Sciences Meeting, 2016. p 0897

Liu Q, Zhang H, Leng J, Chen X (2019) Digital twin-driven rapid individualised designing of automated flow-shop manufacturing system. Int J Prod Res 57(12):3903–3919

Lu Y, Liu C, Kevin I, Wang K, Huang H, Xu X (2020) Digital twin-driven smart manufacturing: connotation, reference model, applications and research issues. Robot Comput Integr Manuf 61:101837

Sun X, Bao J, Li J, Zhang Y, Liu S, Zhou B (2020) A digital twin-driven approach for the assembly-commissioning of high precision products. Robot Comput Integr Manuf 61:101839

Schroeder GN, Steinmetz C, Pereira CE, Espindola DB (2016) Digital twin data modeling with automationml and a communication methodology for data exchange. IFAC-PapersOnLine 49(30):12–17

Botkina D, Hedlind M, Olsson B, Henser J, Lundholm T (2018) Digital twin of a cutting tool. Procedia CIRP 72:215–218

Haag S, Anderl R (2018) Digital twin–proof of concept. Manufacturing Letters 15:64–66

Zhuang C, Liu J, Xiong H (2018) Digital twin-based smart production management and control framework for the complex product assembly shop-floor. Int J Adv Manuf Technol 96(1–4):1149–1163

Boschert S, Rosen R (2016) Digital twin—the simulation aspect. In: Mechatronic futures. Springer 59–74

Erkoyuncu JA, Butala P, Roy R (2018) Digital twins: understanding the added value of integrated models for through-life engineering services. Procedia Manufacturing 16:139–146

Macchi M, Roda I, Negri E, Fumagalli L (2018) Exploring the role of digital twin for asset lifecycle management. IFAC-PapersOnLine 51(11):790–795

Lohtander M, Ahonen N, Lanz M, Ratava J, Kaakkunen J (2018) Micro manufacturing unit and the corresponding 3D-model for the digital twin. Procedia Manufacturing 25:55–61

Brenner B, Hummel V (2017) Digital twin as enabler for an innovative digital shopfloor management system in the ESB Logistics Learning Factory at Reutlingen-University. Procedia Manufacturing 9:198–205

Simons S, Abé P, Neser S (2017) Learning in the AutFab–the fully automated Industrie 4.0 learning factory of the University of Applied Sciences Darmstadt. Procedia Manufacturing 9:81–88

Friedrich C, Lechler A, Verl A (2014) Autonomous systems for maintenance tasks–requirements and design of a control architecture. Procedia Technology 15:595–604

Jain S, Choong NF, Aye KM, Luo M (2001) Virtual factory: an integrated approach to manufacturing systems modeling. Int J Oper Prod Manag

Cai Y, Starly B, Cohen P, Lee Y-S (2017) Sensor data and information fusion to construct digital-twins virtual machine tools for cyber-physical manufacturing. Procedia Manufacturing 10:1031–1042

Frazzon EM, Albrecht A, Hurtado PA (2016) Simulation-based optimization for the integrated scheduling of production and logistic systems. IFAC-PapersOnLine 49(12):1050–1055

Kumar D, Chen Y, Esmaili A (2015) Inclusion of long-term production planning/scheduling into real-time optimization. IFAC-PapersOnLine 48(8):229–233

Kritzinger W, Karner M, Traar G, Henjes J, Sihn W (2018) Digital twin in manufacturing: a categorical literature review and classification. IFAC-PapersOnLine 51(11):1016–1022

Hu L, Nguyen N-T, Tao W, Leu MC, Liu XF, Shahriar MR, Al Sunny SN (2018) Modeling of cloud-based digital twins for smart manufacturing with MT connect. Procedia Manufacturing 26:1193–1203

Qi Q, Tao F, Zuo Y, Zhao D (2018) Digital twin service towards smart manufacturing. Procedia Cirp 72:237–242

Stembridge B (1999) International patent classification in Derwent databases. World Patent Inf 21(3):169–177

Wu J-L, Chang P-C, Tsao C-C, Fan C-Y (2016) A patent quality analysis and classification system using self-organizing maps with support vector machine. Appl Soft Comput 41:305–316

Clarke NS (2018) The basics of patent searching. World Patent Inf 54:S4–S10

Usui S, Palmes P, Nagata K, Taniguchi T, Ueda N (2007) Keyword extraction, ranking, and organization for the neuroinformatics platform. Biosystems 88(3):334–342

Lee S, Yoon B, Park Y (2009) An approach to discovering new technology opportunities: keyword-based patent map approach. Technovation 29(6–7):481–497

Noh H, Jo Y, Lee S (2015) Keyword selection and processing strategy for applying text mining to patent analysis. Expert Syst Appl 42(9):4348–4360

Yoon B, Park Y (2004) A text-mining-based patent network: analytical tool for high-technology trend. The Journal of High Technology Management Research 15(1):37–50

Rokaya M, Atlam E, Fuketa M, Dorji TC, Aoe J-i (2008) Ranking of field association terms using co-word analysis. Inf Process Manag 44(2):738–755

Yoon BU, Yoon CB, Park YT (2002) On the development and application of a self–organizing feature map–based patent map. R&D Manag 32(4):291–300

Chen R (2009) Design patent map visualization display. Expert Syst Appl 36(10):12362–12374

Son C, Suh Y, Jeon J, Park Y (2012) Development of a GTM-based patent map for identifying patent vacuums. Expert Syst Appl 39(3):2489–2500

Larkey LS (1999) A patent search and classification system. Proceedings of the fourth ACM conference on Digital libraries:179–187

Tseng Y-H (2005) Text mining for patent map analysis. Catalyst 5424054(5780101):6333016

Tseng Y-H, Wang Y-M, Lin Y-I, Lin C-J, Juang D-W (2007) Patent surrogate extraction and evaluation in the context of patent mapping. J Inf Sci 33(6):718–736

Kim YG, Suh JH, Park SC (2008) Visualization of patent analysis for emerging technology. Expert Syst Appl 34(3):1804–1812

Lee P-C, Su H-N, Wu F-S (2010) Quantitative mapping of patented technology—the case of electrical conducting polymer nanocomposite. Technol Forecast Soc Chang 77(3):466–478

Hummon NP, Dereian P (1989) Connectivity in a citation network: the development of DNA theory. Soc Networks 11(1):39–63

Verspagen B (2007) Mapping technological trajectories as patent citation networks: a study on the history of fuel cell research. Advances in Complex Systems 10(01):93–115

Liu JS, Lu LY (2012) An integrated approach for main path analysis: development of the Hirsch index as an example. J Am Soc Inf Sci Technol 63(3):528–542

Liu JS, Lu LY, Lu W-M, Lin BJ (2013) Data envelopment analysis 1978–2010: a citation-based literature survey. Omega 41(1):3–15

Wang N, Liang H, Jia Y, Ge S, Xue Y, Wang Z (2016) Cloud computing research in the IS discipline: a citation/co-citation analysis. Decis Support Syst 86:35–47

Yan J, Tseng F-M, Lu LY (2018) Developmental trajectories of new energy vehicle research in economic management: main path analysis. Technol Forecast Soc Chang 137:168–181

Nguyen HH (2018) Privacy-preserving mechanisms for k-modes clustering. Computers & Security 78:60–75

Sajidha S, Chodnekar SP, Desikan K (2018) Initial seed selection for K-modes clustering–a distance and density based approach. J King Saud Univ-Computer Inform Sci

Jiang F, Liu G, Du J, Sui Y (2016) Initialization of K-modes clustering using outlier detection techniques. Inf Sci 332:167–183

Khan SS, Ahmad A (2013) Cluster center initialization algorithm for K-modes clustering. Expert Syst Appl 40(18):7444–7456

Huang Z, Ng MK (1999) A fuzzy k-modes algorithm for clustering categorical data. IEEE Trans Fuzzy Syst 7(4):446–452

Huang Z (1997) A fast clustering algorithm to cluster very large categorical data sets in data mining. DMKD 3(8):34–39

Ayani M, Ganebäck M, Ng AH (2018) Digital twin: applying emulation for machine reconditioning. Procedia CIRP 72:243–248

Graessler I, Poehler A (2018) Intelligent control of an assembly station by integration of a digital twin for employees into the decentralized control system. Procedia Manufacturing 24:185–189

Kunath M, Winkler H (2018) Integrating the digital twin of the manufacturing system into a decision support system for improving the order management process. Procedia CIRP 72:225–231

Talkhestani BA, Jazdi N, Schloegl W, Weyrich M (2018) Consistency check to synchronize the digital twin of manufacturing automation based on anchor points. Procedia CIRP 72(1):159–164

Vathoopan M, Johny M, Zoitl A, Knoll A (2018) Modular fault ascription and corrective maintenance using a digital twin. IFAC-PapersOnLine 51(11):1041–1046

Iglesias D, Bunting P, Esquembri S, Hollocombe J, Silburn S, Vitton-Mea L, Balboa I, Huber A, Matthews G, Riccardo V (2017) Digital twin applications for the JET divertor. Fusion Engineering and Design 125:71–76

Knapp G, Mukherjee T, Zuback J, Wei H, Palmer T, De A, DebRoy T (2017) Building blocks for a digital twin of additive manufacturing. Acta Mater 135:390–399

Uhlemann TH-J, Lehmann C, Steinhilper R (2017) The digital twin: realizing the cyber-physical production system for industry 4.0. Procedia Cirp 61:335–340

Um J, Weyer S, Quint F (2017) Plug-and-simulate within modular assembly line enabled by digital twins and the use of AutomationML. IFAC-PapersOnLine 50(1):15904–15909

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

Appendix 2. The detailed analysis of technology, effect, and application by country

1.1 A2-1. USA

The two-dimensional analysis of patent technology and effect in the USA showed that its major development of four technologies include management technology (Technology #1), wearable device technology (Technology #2), network and communication technology (Technology #3), and data analytics technology (Technology #4). It covers seven types of effects, including technology resolving manufactory operations (Effect #1), data organization and integration (Effect #2), and pattern recognition and classification (Effect #3) (refer to Fig. 7a with solid line). However, there are several patent gaps; for instance, wearable device technology (Technology #2) has not solved issues of manufacturing operations (Effect #1), pattern recognition and classification (Effect #3), disruption, diagnostic, and prevention (Effect #7). For data analytics technology (Technology #4), it has not solved issues of manufacturing operations (Effect #1). In addition, the technology and application matrix showed that the USA mainly developed patents in the manufacturing (Application #1) and general industry (Application #12) (refer to Fig. 7b with solid line).

1.2 A2-2 The World Intellectual Property Organization

Among the patents produced by the WIPO, most were management technology (Technology #1) resolve manufacturing operations (Effect #1) applications, followed by data analysis technology (Technology #4) resolve data organization and integration (Effect #2) and then computing, security, and safety technology (Technology #8) resolve disruptions, diagnostics, and prevention (Effect #7) (refer to Fig. 8a with solid line). Additionally, the technology-application realm matrix shows that the WIPO mainly developed patents in the realms of manufacturing (Application #1) and general industry (Application #12), especially general industry (refer to Fig. 8a with solid line).

1.3 A2-3. China

The patent technology and effect matrix for China (Fig. 9a) showed that currently, China has three focuses in patent technology and effect development. The first part is management technology (Technology #1), wearable device technology (Technology #2), network and communication technology (Technology #3), and data analytics technology (Technology #4), which are used to solve problems in manufacturing operations (Effect #1), data organization and integration (Effect #2), as well as pattern recognition and classification (Effect #3). The second part is management technology (Technology #1), wearable device technology (Technology #2), network and communication technology (Technology #3), and data analytics technology (Technology #4), for resolving issues of communication capability (Effect #6) as well as disruption, diagnostics, and prevention (Effect #7). The third part is sensor technology (Technology #6), optimization and machine learning system (Technology #7), and computing, security, and safety technology (Technology #8), exhibiting seven types of effects, including manufacturing operations (Effect #1) as well as data organization and integration (Effect #2) (refer to Fig. 9a with solid line). But, there are also patent gaps in the more concentrated patent blocks, including management technology (Technology #1) has not solved issues with form decision-making and support (Effect #4), and learning ability and self-organization (Effect #5), wearable device technology (Technology #2) has not solved problems with data organization and integration (Effect #2), pattern recognition and classification (Effect #3), decision-making and support (Effect #4), learning ability and self-organization (Effect #5), network and communication technology (Technology #3) has not solved issues of decision-making and support (Effect #4), data analytics technology (Technology #4) has not solved issues of learning ability and self-organization (Effect #5), optimization and machine learning system (Technology #7) has not solved issues of pattern recognition and classification (Effect #3) (refer to Fig. 9 with dashed line). On the other hand, China revealed in its patent strategies that it did not develop human–machine interfaces technology (Technology #5). Also, its technology and application field matrix shows that China is primarily focused on patent development in general industry (Application #12) (refer to Fig. 9b with solid line).

1.4 A2-4. European Nations

The patent technology and function matrix of the European Nations (EU) (Fig. 10) showed that currently, the EU has three focuses in patent technology and effect development. The first part is management technology (Technology #1), wearable device technology (Technology #2), network and communication technology (Technology #3), data analytics technology (Technology #4), and human–machine interfaces technology (Technology #5), which are used solve problems in manufacturing operations (Effect #1), data organization and integration (Effect #2), as well as pattern recognition and classification (Effect #3). The second part is management technology (Technology #1), wearable device technology (Technology #2), network and communication technology (Technology #3), data analytics technology (Technology #4), and human–machine interfaces technology (Technology #5), which solve problems in learning ability and self-organization (Effect #5), communication capability (Effect #6), as well as disruption, diagnostics, and prevention (Effect #7). The third part is optimization and machine learning system (Technology #7), and computing, security, and safety technology (Technology #8), demonstrating five effects, including manufacturing operations (Effect #1) as well as data organization and integration (Effect #2) (refer to Fig. 10 with solid line).

Nevertheless, there are also patent gaps in the more concentrated patent blocks, including management technology (Technology #1) has solved issues with form data organization and integration (Effect #2), and learning ability and self-organization (Effect #5), wearable device technology (Technology #2) has solved problems with manufacturing operations (Effect #1), pattern recognition and classification (Effect #3), communication capability (Effect #6), and disruption, diagnostic, and prevention (Effect #7), network and communication technology (Technology #3) has solved issues of data organization and integration (Effect #2), and disruption, diagnostic, and prevention (Effect #7), data analytics technology (Technology #4) has solved issues of manufacturing operations (Effect #1), and communication capability (Effect #6), human-machine interfaces technology (Technology #5) has solved issues of pattern recognition and classification (Effect #3), optimization and machine learning system (Technology #7) has solved issues of data organization and integration (Effect #2), pattern recognition and classification (Effect #3), decision-making and support (Effect #4), communication capability (Effect #6), and disruption, diagnostic, and prevention (Effect #7), computing, security and safety technology (Technology #8) has solved issues of manufacturing operations (Effect #1), pattern recognition and classification (Effect #3), decision-making and support (Effect #4), and learning ability and self-organization (Effect #5) (refer to Fig. 10 with dashed line).

The European Patent Office revealed in its patent strategies that it did not develop sensor technology (Technology #6). As for its effects, it did not consider decision support or regulation of this type of effects. Also, its technology and application field matrix (Fig. 10b) showed that the European Patent Office primarily focused on patent development in manufacturing (Application #1) and general industry (Application #12), especially general industry (refer to Fig. 10 with solid line).

Rights and permissions

About this article

Cite this article

Wang, KJ., Lee, TL. & Hsu, Y. Revolution on digital twin technology—a patent research approach. Int J Adv Manuf Technol 107, 4687–4704 (2020). https://doi.org/10.1007/s00170-020-05314-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05314-w