Abstract

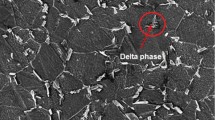

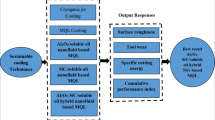

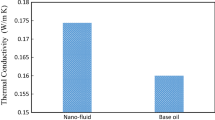

The application of micro-mechanical cutting operations, such as micro-drilling, is crucial for producing microsystem components. In the production of jet engine parts, Inconel 718 superalloy has been used to produce these components due to its high performance at high temperatures. Due to the low thermal conductivity and the high work hardening tendencies of Inconel 718, a high amount of the cutting temperature dissipates toward the cutting tool instead of the chip. When using micro-scale drilling (micro-drilling), heat dissipation becomes more challenging. This affects the tool life and the machined surface quality; therefore, when machining these alloys, a cutting fluid is required to decrease the high amounts of generated heat. Flood coolant is commonly used to reduce the cutting temperature; however, government regulations have been published for alternative cooling processes to decrease the influences of flood coolant on the environment and the operator’s health. Minimum quantity lubrication (MQL) has been used as an alternative to conventional cutting fluids because it minimizes the consumption of cooling lubricants and reduces the environmental and health impacts; however, pure MQL cooling has an ineffective cooling ability. In order to enhance thermal conductivity, viscosity, and wettability of the MQL base fluid, an MQL-nanofluid was used. This study investigated the performance of a micro-drilling process using an MQL-nanofluid with regard to thrust forces, tool wear, and burr formation, and compared it to flood cooling and a pure MQL. Micro-drilling experiments involving Inconel 718 were conducted using the same cutting parameters, drilling tool, and machining environment for both the MQL and the flood coolant. The results revealed that the MQL-nanofluid approach was promising in terms of machining outputs as well as sustainability.

Similar content being viewed by others

References

Metals HS Inconel 718 for aerospace engine applications, Heanjia Super Metals Co. Ltd., 04 04 2016. [Online]. Available: https://super-metals.com/news/inconel-718-for-aerospace-engine-applications/. [Accessed 6 July 2019]

Beer N, Oezkaya E and Biermann D (2014) Drilling of Inconel 718 with geometry-modified twist drills, in Procedia CIRP - New Production Technologies in Aerospace Industry - 5th Machining Innovations Conference (MIC)

Sharif S, Abd Rahim E (2007) Performance of coated-and uncoated-carbide tools when drilling titanium alloy-Ti6Al4V. J Mater Process Technol 185(1–3):72–76

Hegab H, Kishawy H (2018) Towards sustainable machining of Inconel 718 using. J Manuf Mater Process 2(3)

Percin M, Aslantas K, Ucun I, Kaynak Y, Cicek A (2016) Micro-drilling of Ti–6Al–4V alloy: the effects of cooling/lubricating. Precis Eng 45:450–462

M. I. S. Co. Metalworking, MSC Industrial Supply Co., 2019. [Online]. Available: https://www.mscdirect.com/betterMRO/metalworking/micro-drilling-what-you-need-know. [Accessed 10 July 2019]

Nirala CK, Jain Y, Sharma S and Agrawal A (2017) Mechanical micro-drilling and micro-EDM-drilling: a comprehensive and comparative evaluation, in 10th international conference on precision, Meso, Micro and Nano engineering (COPEN-10), India

Bassoli E, Denti L, Gatto A, Iuliano L (2016) Influence of electrode size and geometry in electro-discharge drilling of Inconel 718. Int J Adv Manuf Technol 86(5–8):2329–2337

Feng Y, Guo Y, Ling Z, Zhang X (2019) Micro-holes EDM of superalloy Inconel 718 based on a magnetic suspension spindle system. Int J Adv Manuf Technol 101(5–8):2015–2026

Tanjilul M, Ahmed A, Kumar AS, Rahman M (2018) A study on EDM debris particle size and flushing mechanism for efficient debris removal in EDM-drilling of Inconel 718. J Mater Process Technol 255:263–274

Unune DR, Nirala CK, Mali HS (2019) Accuracy and quality of micro-holes in vibration assisted micro-electro-discharge drilling of Inconel 718. Measurement 135:424–437

D’Urso G, Maccarini G, Ravasio C (2014) Process performance of micro-EDM drilling of stainless steel. Int J Adv Manuf Technol 72:1287–1298

Khandekar S, Sanker M, Agnihotri V, Ramkumar J (2012) Nano-cutting fluid enhancement of metal cutting performance. J Mater Manuf Process 27:963–867

Amrita M, Srikant R, Sitaramaraju A (2014) Performance evaluation of nanographite-based cutting fluid in machining process. J Mater Manuf Process 29:600–605

Li B, Li C, Zhang Y, Wang Y, Jia D, Yang M, Zhang N, Wu Q, Han Z, Sun K (2017) Heat transfer performance of MQL grinding with different nanofluid for Ni-based alloy usingvegetable oil. J Clean Prod 154:1–11

Processors C CarbideProcessors.com, Carbide Processors Inc., 2019. [Online]. Available: http://www.carbideprocessors.com/pages/machine-coolant/bacteria-in-machine-coolant.html. [Accessed 14 7 2019]

Dixit U, Sarma D and Davim JP (2012) Major concerns in using cutting fluids, in Environmentally Friendly Machining, London, SpringerBriefs in Applied Sciences and Technology, pp. 10–11

Boswell B, Islam M, Davies J, Ginting Y, Ong A (2014) A review identifying the effectiveness of minimum quantity lubrication (MQL) during conventional machining. Int J Adv Manuf Technol 72:919–933

Dureja J, Singh R, Singh P, Dogra M, Singh R (2015) Performance evaluation of coated tool in machining of stainless steel (AISI 202) under minimum quantity lubrication (MQL). Int J Precis Eng Manuf Green Technol 2:123–129

Eltaggaz A, Zawada P, Hegab H, Deaib I, Kishawy H (2018) Coolant strategy influence on tool life and surface roughness when machining ADI. Int J Adv Manuf Technol 94:3875–3887

Davim J, Sreejith P, Silva J (2007) Turning of brasses using minimum quantity of lubricat (MQL) and flooded lubricant conditions. Mater Manuf Process 22:45–50

Eltaggaz A, Hegab H, Deiab I and Kishawy H (2017) On using nano-cutting fluid when maching austempered ductile iron," in Proceedings of the 26th CANCAM, Victoria, British Columbia, Canada

Emami M, Sadeghi M, Sarhan A (2013) Investigating the effects of liquid atomization and delivery parameters of minimum quantity lubrication on the grinding process of Al2O3 engineering ceramics. J Manuf Process 15:374–388

Lee P, Nam TS, Li C and Lee SW (2011) Environmentally-friendly nano-fluid minimum quantity lubrication (MQL) meso-scale grinding process using nano-diamond particles, in Manufacturing Automation (ICMA), DOI: https://doi.org/10.1109/ICMA.2010.27

Bhowmick S, Lukitsch M, Alpas A (2010) Dry and minimum quantity lubrication drilling of cast magnesium alloy (AM60). Int J Mach Tools Manuf 50(5):444–457

Nam J, Sang Won L (2017) Machinability of titanium alloy (Ti-6Al-4V) in environmentally-friendly micro-drilling process with nanofluid minimum quantity lubrication using nanodiamond particles. Int J Precis Eng Manuf Green Technol 5(1):29–53

Aslantas K and Çiçek A (2018) The effects of cooling/lubrication techniques on cutting performance in micro-milling of Inconel 718 superalloy, in 8th CIRP Conference on High Performance Cutting, Elsevier Ltd. , Budapest, Hungary

Sun J, Wong Y, Rahman M, Wang Z, Tan C (2016) Effects of coolant supply methods and cutting conditions on tool life in end milling tiyanium alloy. J Mach Sci Technol 10(3):355–370

Vazquez E, Gomar J, Ciurana J, Rodríguez CA (2015) Analyzing effects of cooling and lubrication conditions in micromilling of Ti6Al4V. J Clean Prod 8:906–913

Li K, Chou S (2010) Experimental evaluation of minimum quantity lubrication in near micro-milling. J Mater Process Technol 210(15):2163–2170

Eltaggaz A, Hegab H, Deiab I, Kishawy H (2018) Hybrid nano-fluid-minimum quantity lubrication strategy for machining austempered ductile iron (ADI). Int J Interact Des Manuf 12(4):1273–1281

Kishawy H, Hegab H, Deiab I, Eltaggaz A (2019) Sustainability assessment during machining Ti-6Al-4V with nano-additives-based minimum quantity lubrication. J Manuf Mater Process 3(61)

Huang W-T, Wu D-H, Chen J-T (2016) Robust design of using nanofluid/MQL in micro-drilling. Int J Adv Manuf Technol 85(9–12):2155–2161

Hajiyan M, Ebadil S, Mahmud S, Biglarbegian M, Abdullah H (2018) Experimental investigation of the effect of an external magntic field on the thermal conductivity and viscosity of Fe3O4-glycerol. J Therm Anal Calorim 133:1–14

Eltaggaz A and Deiab I (2018) The effect of nanoparticle concentration on Mql performance when machining Ti-6Al-4V titanium alloy, in Conference: 2018 Canadian Society for Mechanical Engineering (CSME) International Congress, Toronto

Huang WT, Liu WS, Wu DH (2016) Investigations into lubrication in grinding processes using MWCNTs nanofluids with ultrasonic-assisted dispersion. J Clean Prod 137:1553–1559

Shen B, Shih A, Tung S (2008) Application of naofluids in minimum quantity lubrication grinding. Tribol Trans 51:730–737

Shakti C, Eltaggaz A, Deiab I, Khanafer K and Abdul-latif A (2019) Investigation of hybird MQL-nanofluid performance when machining Inconel 718 super-alloy, in The Canadian Society for Mechanical Engineering (CSME) , London, Ontario, Canada

Lee P-H, Nam J, Li C, Lee S (2012) An experimental study on miro-grinding process with nanofluid minimum quantity lubrication (MQL). Int J Precis Eng Manuf 13(3):331–338

Jung SN, Pil-Ho L, Sang WL (2011) Experimental characterization of micro-drilling process using nanofluid. Int J Mach Tools Manuf 51:649–652

Sub KJ, Woo KJ, Won LS (2017) Experimental characterization on micro-end milling of titanium alloy using nanofluid minimum quantity lubrication with chilly gas. Int J Adv Manuf Technol 91:2741–2749

R. A. Company, “Rolled Alloys,” 07 2012. [Online]. Available: https://www.rolledalloys.ca/shared-content/technical-resources/datasheets/718_DS_US_EN.pdf. [Accessed 25 06 2019]

Hasan M, Jingwei Z, Zhengyi J (2017) A review of modern advancements in micro drilling techniques. J Manuf Process 29:343–375

“sowatool,” SOWA Metalworking Solutions, [Online]. Available: http://www.sowatool.com/Catalogue/4/260. [Accessed 25 06 2019]

Deiab I and Raza S (2014) Analysis of lubrication strategies for sustainable machining during turning of titanium Ti-6Al-4V alloy, in CIRP

Eltaggaz A, Deiab I (2019) Comparison of between direct and peck drilling for large aspect. Int J Adv Manuf Technol 102:2797–2805

Americal Products, Americal Products, 08 06 2017. [Online]. Available: https://amprodmfg.com/what-is-deburring/. [Accessed 3 10 2019]

Funding

This work was fully funded by the Kuwait Foundation for the Advancement of Sciences (KFAS) project (PR18-145C-01).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khanafer, K., Eltaggaz, A., Deiab, I. et al. Toward sustainable micro-drilling of Inconel 718 superalloy using MQL-Nanofluid. Int J Adv Manuf Technol 107, 3459–3469 (2020). https://doi.org/10.1007/s00170-020-05112-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05112-4