Abstract

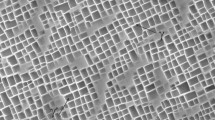

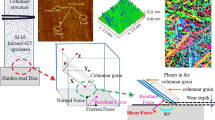

Nickel-based super alloy was used in high mechanical stress applications due to their good creep resistance and oxidation behaviour. However, their undesirable tribological behaviour is the main technical issues in several applications. In this study, nickel-based super alloy CM-247 LC was laser processed in order to improve the tribo-mechanical properties. The metallurgical study was performed using optical microscopy (OM), scanning electron microscopy (SEM) with electron dispersive spectroscopy (EDS) and X-ray diffraction analysis (XRD). The optimized laser parameter shows a significant grain refinement with finely dispersed cell-like structure which enhanced the hardness up to 466 HV0.3. The laser-melted regions were showing with subtle variations in the distribution and shape of γ′ precipitates. XRD spectra were dominated from the γ and γ′ peaks. The maximum weaker reflections were consistent with the occurrence of MC carbides. The wear rates of laser-processed sample were reduced significantly while compared with substrate sample. The examined worn surface specifies that adhesion and abrasion was a significant wear. The phases like γ′ morphology, γ-γ′ eutectics and sizes can influence the tribological behaviour.

Similar content being viewed by others

References

Mostafaei M, Abbasi SM (2015) Influence of Zr content on the incipient melting behavior and stress-rupture life of CM247 LC nickel base superalloy. J Alloys Compd 648:1031–1037

Wang H-S, Kuo Y-L, Kuo C-M, Wei C-N (2016) Microstructural evolution and mechanical properties of hot isostatic pressure bonded CM 247 LC superalloy cast. Mater Des 91:104–110

Guth S, Petrášb R, Škoríkb V, Krumlb T, Manb J, Langa KH, Polákb J (2015) Influence of dwell times on the thermomechanical fatigue behavior of a directionally solidified Ni-base superalloy. Int J Fatigue 80:426–433

Narayanan BK, Muthukannan D, Natarajan S, Khan MA (2017) Laser material processing of nickel superalloy for improved erosion resistance. Mater Manuf Process 32(14):1596–1605

Dube D, Fiset M, Couture A, Nakatsugawa I (2001) Characterization and performance of laser melted AZ91D and AM60B. Mater Sci Eng A 299:38–45

Xi W, Song B, Yu Z, Yu T, Wang J (2019) Geometry and dilution rate analysis and prediction of laser cladding. Int J Adv Manuf Technol 103:4695–4702

Kwok CT, Lo KH, Chan WK, Cheng FT, Man HC (2011) Effect of laser surface melting on intergranular corrosion behaviour of aged austenitic and duplex stainless steels. Corros Sci 53:1581–1591

Vilar R, Santos EC, Ferreira PN, Franco N, Da Silva RC (2009) Acta Mater 57:5292

Majumdar JD, Galun R, Mordike BL, Manna I (2003) Effect of laser surface melting on corrosion and wear resistance of a commercial magnesium alloy. Mater Sci Eng A 361:119

Darmawan W, Quesada J, Marchal R (2007) Characteristics of laser melted AISI-Ti high speed steel and its wear resistance. Surf Eng 23:112

Shankar AR, Babu BJ, Sole R, Kamachi Mudali U, Khatak HS (2013) Laser remelting of plasma sprayed zirconia based ceramic coating for pyrochemical reprocessing applications surf. Eng. 23:147

Huang C, Zhang Y, Vilar R, Shen J (2012) Dry sliding wear behavior of laser clad TiVCrAlSi high entropy alloy coatings on Ti–6Al–4V substrate. Mater Design 41:338

Jufang C, Xingcheng L, Renxing L, Laidi S (2010) Enhancement of corrosion resistance of nickel based superalloys by laser surface melting. Appl Mech Mater 33:607

Shariff SM, Pal TK, Padmanabham G, Joshi SV (2010) Sliding wear behaviour of laser surface modified pearlitic rail steel. Surf Eng 26:199

Jeyaprakash N, Yang C-H, Tseng S-P (2019) Characterization and tribological evaluation of NiCrMoNb and NiCrBSiC laser cladding on near-α titanium alloy. Int J Adv Manuf Technol:1–15. https://doi.org/10.1007/s00170-019-04755-2

Cui CY, Cui XG, Zhang YK, Zhao Q, Lu JZ, Hu JD, Wang YM (2011) Microstructure and corrosion behavior of the AISI 304 stainless steel after Nd:YAG pulsed laser surface melting. Surf Coat Tech 206:1146

Colaco R, Vilar R (2004) Stabilisation of retained austenite in laser surface melted tool steels. Mater Sci Eng A 385:123

Liu Z, Liu H, Viejo F, Aburas Z, Rakhes M (2010) Laser-induced microstructural modification for corrosion protection. J Mech Eng Sci 224:1073

Hashim M, Babu KESR, Duraiselvam M, Natu H (2013) Improvement of wear resistance of Hastelloy C-276 through laser surface melting. Mater Des 46:546–551

Campanelli SL, Angelastro A, Posa P, Daurelio G (2018) Fiber laser surface remelting of a nickel-based superalloy by an integrated rectangular laser spot. Opt Lasers Eng 111:42–49

Liang YJ, Wang HM (2016) Origin of stray-grain formation and epitaxy loss at substrate during laser surface remelting of single-crystal nickel-base superalloys. Mater Des 102:297–302

Munoz-Moreno R, Divya VD, Driver SL, Messe OMDM, Illston T, Baker S, Carpenter MA, Stone HJ (2016) Effect of heat treatment on the microstructure, texture and elastic anisotropy of the nickel-based superalloy CM247 LC processed by selective laser melting. Mater Sci Eng A 674:529–539

Yilbas BS, Akhtar SS, Karatas C (2010) Laser surface treatment of Inconel 718 alloy: thermal stress analysis. Opt Lasers Eng 48:740–749

Wang C, Shen XJ, An ZB, Zhou LC, Chai Y (2016) Effects of laser shock processing on microstructure and mechanical properties of K403 nickel-alloy. Mater Des 89:582–588

Standard test method for wear testing with a pin-on-disk apparatus, ASTM Standard, 2010, G: 99–05

Rai RK, Sahu JK, Jena PSM, Das SK, Paulose N, Fernando CD (2017) High temperature tensile deformation of a directionally solidified nickel base superalloy: role of micro constituents. Mater Sci Eng A 705:189–195

Youdelis WV, Kwon O (2013) Carbide phases in nickel base superalloy: nucleation properties of MC type carbide. Metal Sci 17:385–388

Sims CT, Stoloff NS, Hagel WC (1987) Superalloys II, New York

Huang HE, Koo CH (2004) Effect of solution-treatment on microstructure and mechanical properties of cast fine-grain CM247LC superalloy. Mater Trans 45:1360–1366

Divya VD, Munoz-Moreno R, Messe OMDM, Barnard JS, Baker S, Illston T, Stone HJ (2016) Microstructure of selective laser melted CM247LC nickel-based superalloy and its evolution through heat treatment. Mater Charact 114:62–74

Kesavan D, Kamaraj M (2010) The microstructure and high temperature wear performance of a nickel base hard faced coating. Surf Coat Technol 204:4034–4043

Gholipour A, Shamanian M, Ashrafizadeh F (2011) Microstructure and wear behavior of stellite 6 cladding on 17-4 PH stainless steel. J Alloys Compd 509:4905–4909

Chakraborty G, Kumar N, Das CR, Albert SK, Bhaduri AK, Dash S, Tyagi AK (2014) Study on microstructure and wear properties of different nickel base hardfacing alloys deposited on austenitic stainless steel. Surf Coat Technol 244:180–188

Funding

This research work received financial support from the Ministry of Science and Technology (MOST), Taiwan, Republic of China (R.O.C).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jeyaprakash, N., Yang, CH. Improvement of tribo-mechanical properties of directionally solidified CM-247 LC nickel-based super alloy through laser material processing. Int J Adv Manuf Technol 106, 4805–4814 (2020). https://doi.org/10.1007/s00170-020-04931-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-04931-9