Abstract

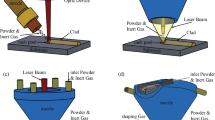

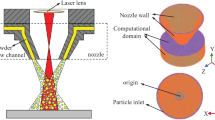

High power diode laser (HPDL) characterized by a wider rectangle beam spot (RBS) with top-hat intensity distribution is particularly applied in laser metal deposition to manufacture large-scale components. In order to design a coaxial nozzle with rectangular outlet to match the RBS of the HPDL, a novel wide-beam coaxial feeding nozzle (WBCFN) outlet is proposed. Based on the gas-powder flow model established in ANSYS FLUENT, the influence of structural parameters of the new coaxial nozzle on the gas flow and powder distribution is investigated. Two quantitative indexes are defined to seek out the optimal designing scheme that minimize the divergences of the powder flow and uniform the powder distribution in transverse and longitudinal directions. And then, the effect and sensitivity of structural parameters on concentration distribution and focal length of powder flow are analyzed. The results indicate that the two indexes increase with the increase of exit width, while the variance of concentration firstly increases and then decreases with the increase of the chamber length and inclination angle. The focal length decreases with the increase of inclination angle. Finally, the optimal solution of designing scheme is obtained through comprehensive analysis, and experiments are carried out to validate the model, which indicates that the designed WBCFN can acquire good morphology and quality of deposition layer for HPDL.

Similar content being viewed by others

References

Tabernero I, Lamikiz A, Ukar E, Martínez S, Celaya A (2014) Modeling of the geometry built-up by coaxial laser material deposition process. Int J Adv Manuf Technol 70:843–851. https://doi.org/10.1007/s00170-013-5284-3

Liu H, Qin X, Huang S, Hu Z, Ni M (2018) Geometry modeling of single track cladding deposited by high power diode laser with rectangular beam spot. Opt Lasers Eng 100:38–46. https://doi.org/10.1016/j.optlaseng.2017.07.008

Lei K, Qin X, Liu H, Ni M (2018) Analysis and modeling of melt pool morphology for high power diode laser cladding with a rectangle beam spot. Opt Lasers Eng 110:89–99. https://doi.org/10.1016/j.optlaseng.2018.05.022

Liu S, Zhang Y, Kovacevic R (2015) Numerical simulation and experimental study of powder flow distribution in high power direct diode laser cladding process. Lasers Manuf Mater Process 2:199–218. https://doi.org/10.1007/s40516-015-0015-2

Takemura S, Koike R, Kakinuma Y, Sato Y, Oda Y (2019) Design of powder nozzle for high resource efficiency in directed energy deposition based on computational fluid dynamics simulation. Int J Adv Manuf Technol 105:4107–4121. https://doi.org/10.1007/s00170-019-03552-1

Gong X, Zhang Y, Liu M (2013) Powder transport model for laser cladding by lateral powder feeding: I. Powder flow field with cylindrical distribution. Int J Adv Manuf Technol 67:2501–2509. https://doi.org/10.1007/s00170-012-4667-1

Lamikiz A, Tabernero I, Ukar E, Martinez S, Lopez L, Luis N (2011) Current designs of coaxial nozzles for laser cladding. Recent Patents Mech Eng 4:29–36. https://doi.org/10.2174/2212797611104010029

Lin J (2000) Numerical simulation of the focused powder streams in coaxial laser cladding. J Mater Process Technol 105:17–23. https://doi.org/10.1016/S0924-0136(00)00584-7

Balu P, Leggett P, Kovacevic R (2012) Parametric study on a coaxial multi-material powder flow in laser-based powder deposition process. J Mater Process Technol 212:1598–1610. https://doi.org/10.1016/j.jmatprotec.2012.02.020

Grigoryants AG, Tretyakov RS, Shiganov IN, Stavertiy AY (2015) Optimization of the shape of nozzles for coaxial laser cladding. Weld Int 29:639–642. https://doi.org/10.1080/01431161.2014.967043

Cortina M, Arrizubieta JI, Ruiz JE, Lamikiz A, Ukar E (2018) Design and manufacturing of a protective nozzle for highly reactive materials processing via laser material deposition. Procedia CIRP 68:387–392. https://doi.org/10.1016/j.procir.2017.12.100

Kovalev OB, Kovaleva IO, Smurov IY (2017) Numerical investigation of gas-disperse jet flows created by coaxial nozzles during the laser direct material deposition. J Mater Process Technol 249:118–127. https://doi.org/10.1016/j.jmatprotec.2017.05.041

Arrizubieta JI, Tabernero I, Ruiz JE, Lamikiz A, Martinezb S, Ukarb E (2014) Continuous coaxial nozzle design for LMD based on numerical simulation. Phys Procedia 56:429–438. https://doi.org/10.1016/j.phpro.2014.08.146

Zhang A, Li D, Zhou Z, Zhu G, Lu B (2010) Numerical simulation of powder flow field on coaxial powder nozzle in laser metal direct manufacturing. Int J Adv Manuf Technol 49:853–859. https://doi.org/10.1007/s00170-010-2657-8

Kovalev OB, Bedenko DV, Zaitsev AV (2018) Development and application of laser cladding modeling technique: from coaxial powder feeding to surface deposition and bead formation. Appl Math Model 57:339–359. https://doi.org/10.1016/j.apm.2017.09.043

Zekovic S, Dwivedi R, Kovacevic R (2007) Numerical simulation and experimental investigation of gas-powder flow from radially symmetrical nozzles in laser-based direct metal deposition. Int J Mach Tools Manuf 47:112–123. https://doi.org/10.1016/j.ijmachtools.2006.02.004

Tan H, Zhang F, Fu X, Meng J, Hu G, Fan W, Huang W (2016) Development of powder flow model of laser solid forming by analysis method. Int J Adv Manuf Technol 82:1421–1431. https://doi.org/10.1007/s00170-015-7481-8

Katinas C, Shang W, Shin YC, Chen J (2018) Modeling particle spray and capture efficiency for direct laser deposition using a four nozzle powder injection system. J Manuf Sci Eng 140:041014. https://doi.org/10.1115/1.4038997

Liu S, Kovacevic R (2014) Statistical analysis and optimization of processing parameters in high-power direct diode laser cladding. Int J Adv Manuf Technol 74:867–878. https://doi.org/10.1007/s00170-014-6041-y

Orszag SA, Yakhot V, Flannery WS, Boysan F, Choudhury D, Maruzewski J, Patel B (1993) Renormalization group modeling and turbulence simulations. Int Conf Near-Wall Turbul Flows, Tempe

Liu H, He XL, Yu G, Wang ZB, Li SX, Zheng CY, Ning WJ (2015) Numerical simulation of powder transport behavior in laser cladding with coaxial powder feeding. Sci China Physics, Mech Astron 58:104701–104710. https://doi.org/10.1007/s11433-015-5705-4

Yan J, Battiato I, Fadel G (2017) Design of injection nozzle in direct metal deposition (DMD) manufacturing of thin-walled structures based on 3D models. Int J Adv Manuf Technol 91:605–616. https://doi.org/10.1007/s00170-016-9773-z

Pinkerton AJ, Li L (2002) A verified model of the behaviour of the axial powder stream concentration from a coaxial laser cladding nozzle Proceedings of ICALEO 165528. https://doi.org/10.2351/1.5066174

Pinkerton AJ, Lin L (2004) Modelling powder concentration distribution from a coaxial deposition nozzle for laser-based rapid tooling. J Manuf Sci Eng 126:33–41. https://doi.org/10.1115/1.1643748

Liu J, Li L (2005) Study on cross-section clad profile in coaxial single-pass cladding with a low-power laser. Opt Laser Technol 37:478–482. https://doi.org/10.1016/j.optlastec.2004.07.010

Mondal S, Paul CP, Kukreja LM, Bandyopadhyay A, Pal PK (2013) Application of Taguchi-based gray relational analysis for evaluating the optimal laser cladding parameters for AISI1040 steel plane surface. Int J Adv Manuf Technol 66:91–96. https://doi.org/10.1007/s00170-012-4308-8

Liu H, Hu Z, Qin X, Wang Y, Zhang J, Huang S (2017) Parameter optimization and experimental study of the sprocket repairing using laser cladding. Int J Adv Manuf Technol 91:3967–3975. https://doi.org/10.1007/s00170-017-0066-y

Funding

This work was supported by the National Key R&D Program of China (Grant No. 2018YFB1106500) and the National Natural Science Foundation of China (Grant No.51575415). The authors gratefully thank all staffs of Hubei Key Laboratory of Advanced Technology for Automotive Components for supporting this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ni, M., Qin, X., Liu, H. et al. Analysis and design of coaxial nozzle with rectangular outlet for high power diode laser in laser metal deposition. Int J Adv Manuf Technol 106, 4789–4803 (2020). https://doi.org/10.1007/s00170-019-04874-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04874-w