Abstract

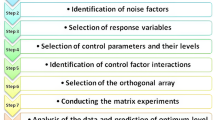

The effect of various laser cladding process parameters like laser power, scan speed, and powder feed rate on clad bead quality characteristics (or clad bead geometry) for AISI 1040 steel substrate have been studied by performing a number of experiments with L 9 orthogonal array. In order to find the process parametric setting for best quality clad bead based on experimental results, a multiresponse optimization technique using gray relational analysis (GRA) is presented in this paper. The GRA is applied on laser cladding process to find out the gray relational grade for each experiment. On optimization, power of 1.25 kW, scan speed of 0.8 m/min, and a powder feed rate of 11 gm/min have been found to be the best parametric setting for laser cladding operation of AISI 1040 steel substrate. Moreover, the analysis of variance is also performed to determine the contribution of each control factor on the clad quality characteristics. Finally, to ensure the robustness of GRA, a confirmatory test is performed at selected optimal parametric setting.

Similar content being viewed by others

References

H. Gedda, Laser surface cladding a literature survey. 2000:07. ISSN: 1402-1536. ISRN: LTU-TR—00/07—SE

Li Y, Jian Ma (1997) Study on overlapping in the laser cladding process. Surf Coat Technol 90:l–5

Mondal S, Bandyopadhyay A, Pal PK (2011) Ni-Cr-Mo cladding on mild steel surface using CO2 laser and process modeling with response surface methodology (RSM). Int J Eng Sci Technol 3:6805–6811

G. Chryssolouris, S. Zannis, K. Tsirbas, C. Lalas. An experimental investigation of laser cladding. Department of Mechanical Engineering and Aeronautics. University of Patras, Greece

Paulo Davim J, Oliveira C, Cardoso A (2008) Predicting the geometric form of clad in laser cladding by powder using multiple regression analysis (MRA). Mater Des 29:554–557

Narender Singh P, Raghukandan K, Pai BC (2004) Optimization by grey relational analysis of EDM parameters on machining Al–10%SiCP composites. J Mater Proc Technol 155–156:1658–1661

Lin JL, Lin CL (2002) The use of the orthogonal array with grey relational analysis to optimize the electrical discharge machining process with multiple performance characteristics. Int J Mach Tool Manuf 42:237–244

Tsai MJ, Li CH (2009) The use of grey relational analysis to determine laser cutting parameters for QFN packages with multiple performance characteristics. Opt Laser Technol 41:914–921

Fu C, Zheng J, Zhao J, Xu W (2001) Application of grey relational analysis for corrosion failure of oil tubes. Corros Sci 43:881–889

Acherjee B, Kuar AS, Mitra S, Misra D (2011) Application of grey-based Taguchi method for simultaneous optimization of multiple quality characteristics in laser transmission welding process of thermoplastics. Int J Adv Manuf Tech 56:995–1006. doi:10.1007/s00170-011-3224-7

Kuar AS, Acherjee B, Ganguly D, Mitra S (2011) Optimization of Nd:YAG laser parameters for micro-drilling of alumina with multi-quality characteristics via gray-Taguchi method. Mater Manuf Process. doi:10.1080/10426914.2011.585493

Paul CP, Ganesh P, Mishra SK, Bhargavaa P, Negib J, Nath AK (2007) Investigating laser rapid manufacturing for Inconel-625 components. Opt Laser Technol 39:800–805

Kung CY, Wen KL (2007) Applying grey relational analysis and grey decision-making to evaluate the relationship between company attributes and its financial performance—a case study of venture capital enterprises in Taiwan. Decis Support Syst 43:842–852

Tzenga CJ, Linb YH, Yanga YK, Jeng MC (2009) Optimization of turning operations with multiple performance characteristics using the Taguchi method and grey relational analysis. J Mater Proc Technol 2 0 9:2753–2759

Chiang Yu-Min, Hsieh HH (2009) The use of the Taguchi method with grey relational analysis to optimize the thin-film sputtering process with multiple quality characteristic in color filter manufacturing. Comput Ind Eng 56:648–661

R. Schäfer Rules for using multi-attribute utility theory for estimating a user's interests. DFKI GmbH, Stuhlsatzenhausweg 3, 66123 Saarbrücken

Antony J (2000) Multi-response optimization in industrial experiments using Taguchi's quality loss function and principal component analysis. Quality and reliability engineering international. Qual Reliab Engng 16:3–8

M. S. Phadke Quality engineering using robust design. Prentice Hall, Englewood Cliffs, New Jersey 07632

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mondal, S., Paul, C.P., Kukreja, L.M. et al. Application of Taguchi-based gray relational analysis for evaluating the optimal laser cladding parameters for AISI1040 steel plane surface. Int J Adv Manuf Technol 66, 91–96 (2013). https://doi.org/10.1007/s00170-012-4308-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4308-8