Abstract

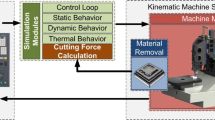

For so many years, virtual manufacturing has been regarded as an important tool for machining path planning. Without a doubt, this tool could also be used for abrasive water jet cutting process. However, different from a rigid knife, abrasive water jet (AWJ) is a soft knife. Its edge pattern is changing as the process parameters change. Therefore, the traditional virtual manufacturing method, which is very effective for a hard knife manufacturing, could not be used directly in simulating the cutting process with a soft knife. A new virtual cutting method, in which the edge pattern of the knife is changing dynamically, has been explored in this paper. To verify the effectiveness of this new method, the virtual cutting results have been compared with the real cutting results. Based on the verification, the new method presented in this paper is very helpful in correcting the shape errors showed in real cutting process.

Similar content being viewed by others

References

Zhang S, Li X, Gu Y (2009) Air flow exploration of abrasive feed tube. Acta Mech Sinica 25(6):761–768

Chen M, Zhang S, Zeng J, Chen B (2019) Correcting shape error located in cut-in/cut-out region in abrasive water jet cutting process. Int J Adv Manuf Technol 102:1165–1178. https://doi.org/10.1007/s00170-018-3123-2

Krajcarz D (2014) Comparison metal water jet cutting with laser and plasma cutting. Procedia Eng 69(1):838–843

Finnie I (1958) The mechanism of erosion of ductile metals. Proceedings of the Third National Congress on Applied Mechanics, New York, pp 527–532

Hashish M (1987) Modified model for erosion. Seventh International Conference on Erosion by Liquid and Solid Impact, Cambridge, England, pp 461–480

Lebar A, Junkar M (2003) Simulation of abrasive waterjet machining based on unit event features. Proc Inst Mech Eng B J Eng Manuf 217(5):699–703

Eltobgy MS, Ng E, Elbestawi MA (2005) Finite element modeling of erosive wear. Int J Mach Tool Manu 45(11):1337–1346

Feng L, Liu GR, Li Z, Dong X, Du M (2019) Study on the effects of abrasive particle shape on the cutting performance of Ti-6Al-4V materials based on the SPH method. Int J Adv Manuf Technol 101:3167

Liu X, Liang Z, Wen G, Yuan X (2019) Waterjet machining and research developments: a review. Int J Adv Manuf Technol 102:1257–1335

Hashish M (1984) On the modeling of abrasive-waterjet cutting. Proceedings of the 7th International Symposium on Jet Cutting Technology, June 26-28 Ottawa, Canada, pp 249–265

Matsui S, Matsumura H, Ikemoto Y, Tsujita K (1990) High precision cutting method for metallic materials by abrasive waterjet. in D. Saunders (Ed.), Jet cutting technology - Proceedings of the 10th International Symposium, Amsterdam, The Netherlands October 31 - November 2, pp 263–278

Zeng J, Kim TJ (1992) Development of an abrasive waterjet kerf cutting model for brittle materials. Jet cutting technology, pp 83–501

Zeng J (2007) Determination of machinability and abrasive cutting properties in AWJ cutting. 2007 American WJTA Conference and Expo, August 19-21, 2007, Houston, Texas, pp 19–21

Henning A (1997) Computer aided manufacturing for three-dimensional abrasive water jet machining. 1997 American Waterjet Conference, August 23-26, 1997, Dearborn, Michigan, pp 729–742

Olsen J, Zeng J, Guglielmetti B (2003) Advanced error correction methodology applied to abrasive waterjet cutting. 2003 WJTA American Waterjet Conference, August 17–19, 2003, Houston, Texas

Hashish M (2007) Benefits of dynamic waterjet angle compensation. 2007 American WJTA Conference and Expo, Houston, Texas, USA 1-H

Kitamura M, Ishikawa M, Sudo K, Yamaguchi Y, Ishimura T, Tujita K (1992) Cutting of steam turbine components using an abrasive water jet. Jet Cutting Technology. Springer, Dordrecht, pp 543–554

Min J (2004) Application of Boolean operation to turning simulation. Dalian Jiaotong University, Dalian

Zeng J, Henning A (2009) Kerf characterization in abrasive waterjet cutting. 2009 American WJTA conference, august 18-20, 2009, Houston, Texas 1-H

Hashish M (1988) Visualization of the abrasive waterjet cutting process. Exp Mech 28(2):159–169

Zeng J, Heines R, Kim T J (1991) Characterization of energy dissipation phenomenon in abrasive waterjet cutting. Proceedings of the 6th American waterjet conference, Houston, Texas pp 163–177

Friedrich R, Radons G, Ditzinger T, Henning A (2000) Ripple formation through an interface instability from moving growth and erosion sources. Phys Rev Lett 85(23):4884–4887

Henning A, Westkamper E, Schmidt B (2004) Analysis of geometry at abrasive waterjet cutting operation. Proceedings of the 17th international conference on water jetting-advances and futureneeds, Mainz, Germany 465–474

Henning A, Westkamper E (2007) Dynamic analysis of the spatialtemporal behaviour of the cutting front in abrasive waterjet cutting. American WJTA Conference and Expo, Houston, Texas

Groppetti R, Gutema T, Lucchio A D (1998) A contribution to the analysis of some kerf quality attributes for precision abrasive waterjet cutting. The 14th international conference on jetting technology. Brugge, Belgium, pp 253–269

Annoni M, Monno M (2000) A lower limit for the feed rate in AWJ precision machining. Proceedings of the 15th international conference on jetting technology, Ronneby, pp 285–296

Wu Y (2015) Fundamental research of 3D model in accurate abrasive water jet cutting. Chongqing University, Chongqing

Wang S, Zhang S, Wu Y, Yang F (2017) Exploring kerf cut byabrasive waterjet. Int J Adv Manuf Technol 93(5–8):2013–2020

Chen M, Zhang S, Zeng J, Chen B, Xue J, Ji L (2019) Correcting shape error on external corners caused by the cut-in/cut-out process in abrasive water jet cutting. Int J Adv Manuf Technol 103:849–859. https://doi.org/10.1007/s00170-019-03564-x

Funding

This work was supported by the National Natural Science Foundation of China (grant number 51675320).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, M., Zhang, S. & Zeng, J. Exploring the effectiveness of a self-defined virtual cutting method with a “soft knife”. Int J Adv Manuf Technol 106, 3007–3015 (2020). https://doi.org/10.1007/s00170-019-04803-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04803-x