Abstract

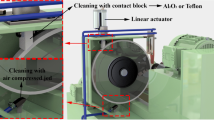

The minimum quantity lubrication + nanofluid technique has proven to be feasible in machining processes, since it has shown potential for improvements through its lubri-refrigeration and heat removal characteristics, beyond increase the surface quality workpiece surface, while minimizing diametrical wheel wear. Also, the nanofluids are associated with decreasing the grinding power corroborates for process efficiency. In this way, this work evaluates the combination of the MQL + nanofluid (MQL + Nano) technique and compares its results with the cutting fluid abundant application (Flood) technique, traditional MQL and MQL associated with wheel cleaning jet (MQL + WCJ). Accordingly, the process output variables were analyzed: surface roughness (Ra), roundness error, diametral wheel wear, optical microscopy and microhardness from the workpiece ground surface, grinding power, specific energy grinding, acoustic emission, cutting fluid viscosity and transmission electron microscopy of the TiO2 nanoparticle used. The techniques applied in this work did not cause microstructural alteration in the workpieces, proving that the lubri-refrigeration methods are efficient. Even though the cutting fluid viscosity decreased by about 60% with the addition of TiO2 nanoparticles and the application of the MQL + Nano technique proved to be efficient in comparison to the traditional MQL, the MQL + WCJ application presented the best results among the alternative lubri-refrigeration techniques. Thereby, the MQL + WCJ corroborated to a better workpiece surface quality, while presented the lower diametrical wheel wear, surface roughness and roundness error values, contributing to the minimization of the industrial residues and cooperating with the environment and health of the worker.

Similar content being viewed by others

References

Javaroni RL, Lopes JC, Sato BK, Sanchez LEA, Mello HJ, Aguiar PR, Bianchi EC (2019) Minimum quantity of lubrication (MQL) as an eco-friendly alternative to the cutting fluids in advanced ceramics grinding. Int J Adv Manuf Technol 103:2809–2819. https://doi.org/10.1007/s00170-019-03697-z

Bianchi EC, Rodriguez RL, Hildebrandt RA et al (2018) Plunge cylindrical grinding with the minimum quantity lubrication coolant technique assisted with wheel cleaning system. Int J Adv Manuf Technol 95:2907–2916. https://doi.org/10.1007/s00170-017-1396-5

Malkin S, Guo C (2008) Grinding technology: theory and applications of machining with abrasives, 2a edn. Industrial Press Inc, New York

Silva LR, Catai RE, Fusse RY, Aguiar PR (2005) Study on the behavior of the minimum quantity lubricant - MQL technique under different lubricating and cooling conditions when grinding ABNT 4340 steel. XXVII

Lopes JC, de Martini FL, Domingues BB et al (2019) Effect of CBN grain friability in hardened steel plunge grinding. Int J Adv Manuf Technol 103:1567–1577. https://doi.org/10.1007/s00170-019-03654-w

de Martini FL, Lopes JC, Volpato RS et al (2018) Comparative analysis of two CBN grinding wheels performance in nodular cast iron plunge grinding. Int J Adv Manuf Technol 98:237–249. https://doi.org/10.1007/s00170-018-2133-4

de Mello HJ, de Mello DR, Rodriguez RL et al (2018) Contribution to cylindrical grinding of interrupted surfaces of hardened steel with medium grit wheel. Int J Adv Manuf Technol 95:4049–4057. https://doi.org/10.1007/s00170-017-1552-y

da Silva LR, Bianchi EC, Fusse RY et al (2007) Analysis of surface integrity for minimum quantity lubricant—MQL in grinding. Int J Mach Tools Manuf 47:412–418. https://doi.org/10.1016/j.ijmachtools.2006.03.015

Hadad M, Sharbati A (2016) Thermal aspects of environmentally friendly-MQL grinding process. Procedia CIRP 40:509–515. https://doi.org/10.1016/j.procir.2016.01.125

Obikawa T, Takemura Y, Akiyama Y et al (2009) Microscopic phase-dependent residual stresses in the machined surface layer of two-phase alloy. J Mater Process Technol 209:4496–4501. https://doi.org/10.1016/j.jmatprotec.2008.10.039

de Jesus Oliveira D, Guermandi LG, Bianchi EC et al (2012) Improving minimum quantity lubrication in CBN grinding using compressed air wheel cleaning. J Mater Process Technol 212:2559–2568. https://doi.org/10.1016/j.jmatprotec.2012.05.019

Rowe WB Principles of Modern Grinding Technology Principles of Modern Grinding Technology Second Edition

Rodriguez RL, Lopes JC, Hildebrandt RA et al (2019) Evaluation of grinding process using simultaneously MQL technique and cleaning jet on grinding wheel surface. J Mater Process Technol 271:357–367. https://doi.org/10.1016/j.jmatprotec.2019.03.019

Bianchi EC, Sato BK, Sales AR, Lopes JC, Mello HJ, Angelo Sanchez LE, Diniz AE, Aguiar PR (2018) Evaluating the effect of the compressed air wheel cleaning in grinding the AISI 4340 steel with CBN and MQL with water. Int J Adv Manuf Technol 95:2855–2864. https://doi.org/10.1007/s00170-017-1433-4

Tunc LT, Gu Y, Burke MG (2016) Effects of minimal quantity lubrication (MQL) on surface integrity in robotic milling of austenitic stainless steel. Procedia CIRP 45:215–218. https://doi.org/10.1016/j.procir.2016.02.337

Maruda RW, Krolczyk GM, Wojciechowski S, Zak K, Habrat W, Nieslony P (2018) Effects of extreme pressure and anti-wear additives on surface topography and tool wear during MQCL turning of AISI 1045 steel. J Mech Sci Technol 32:1585–1591. https://doi.org/10.1007/s12206-018-0313-7

Ekinovic S, Prcanovic H, Begovic E (2015) Investigation of influence of MQL machining parameters on cutting forces during MQL turning of carbon steel St52-3. Procedia Eng 132:608–614. https://doi.org/10.1016/j.proeng.2015.12.538

(2015) Research on emulsion mist generation in the conditions of minimum quantity cooling lubrication (MQCL). Teh Vjesn - Tech Gaz 22. https://doi.org/10.17559/TV-20140423221850

Uysal A, Demiren F, Altan E (2015) Applying minimum quantity lubrication (MQL) method on milling of martensitic stainless steel by using Nano Mos2 reinforced vegetable cutting fluid. Procedia - Soc Behav Sci 195:2742–2747. https://doi.org/10.1016/j.sbspro.2015.06.384

Lopes JC, Ventura CEH, de Fernandes LM et al (2019) Application of a wheel cleaning system during grinding of alumina with minimum quantity lubrication. Int J Adv Manuf Technol 102:333–341. https://doi.org/10.1007/s00170-018-3174-4

Wojtewicz M, Nadolny K, Kapłonek W, Rokosz K, Matýsek D, Ungureanu M (2019) Experimental studies using minimum quantity cooling (MQC) with molybdenum disulfide and graphite-based microfluids in grinding of Inconel® alloy 718. Int J Adv Manuf Technol 101:637–661. https://doi.org/10.1007/s00170-018-2935-4

Maruda RW, Krolczyk GM, Feldshtein E et al (2016) A study on droplets sizes, their distribution and heat exchange for minimum quantity cooling lubrication (MQCL). Int J Mach Tools Manuf 100:81–92. https://doi.org/10.1016/j.ijmachtools.2015.10.008

Bianchi EC, Rodriguez RL, Hildebrandt RA et al (2019) Application of the auxiliary wheel cleaning jet in the plunge cylindrical grinding with minimum quantity lubrication technique under various flow rates. Proc Inst Mech Eng Part B J Eng Manuf 233:1144–1156. https://doi.org/10.1177/0954405418774599

Jia D, Li C, Zhang Y, Yang M, Zhang X, Li R, Ji H (2019) Experimental evaluation of surface topographies of NMQL grinding ZrO2 ceramics combining multiangle ultrasonic vibration. Int J Adv Manuf Technol 100:457–473. https://doi.org/10.1007/s00170-018-2718-y

Daungthongsuk W, Wongwises S (2007) A critical review of convective heat transfer of nanofluids. Renew Sust Energ Rev 11:797–817. https://doi.org/10.1016/j.rser.2005.06.005

Saidur R, Leong KY, Mohammad HA (2011) A review on applications and challenges of nanofluids. Renew Sust Energ Rev 15:1646–1668. https://doi.org/10.1016/j.rser.2010.11.035

Kakaç S, Pramuanjaroenkij A (2009) Review of convective heat transfer enhancement with nanofluids. Int J Heat Mass Transf 52:3187–3196. https://doi.org/10.1016/j.ijheatmasstransfer.2009.02.006

Xia W, Zhao J, Wu H et al (2017) Effects of oil-in-water based nanolubricant containing TiO2 nanoparticles in hot rolling of 304 stainless steel. Procedia Eng 207:1385–1390. https://doi.org/10.1016/j.proeng.2017.10.901

Nguyen CT, Desgranges F, Roy G et al (2007) Temperature and particle-size dependent viscosity data for water-based nanofluids – hysteresis phenomenon. Int J Heat Fluid Flow 28:1492–1506. https://doi.org/10.1016/j.ijheatfluidflow.2007.02.004

Wang Y, Li C, Zhang Y et al (2017) Experimental evaluation on tribological performance of the wheel/workpiece interface in minimum quantity lubrication grinding with different concentrations of Al2O3 nanofluids. J Clean Prod 142:3571–3583. https://doi.org/10.1016/j.jclepro.2016.10.110

Dai W, Kheireddin B, Gao H, Liang H (2016) Tribology international roles of nanoparticles in oil lubrication $. Tribiology Int 102:88–98. https://doi.org/10.1016/j.triboint.2016.05.020

Gu Y, Zhao X, Liu Y, Lv Y (2014, 2014) Preparation and tribological properties of dual-coated TiO2 nanoparticles as water-based lubricant additives. J Nanomater. https://doi.org/10.1155/2014/785680

Yang G, Zhang Z, Zhang S et al (2013) Synthesis and characterization of highly stable dispersions of copper nanoparticles by a novel one-pot method. Mater Res Bull 48:1716–1719. https://doi.org/10.1016/j.materresbull.2013.01.025

Debnath S, Reddy MM, Yi QS (2014) Environmental friendly cutting fl uids and cooling techniques in machining : a review. J Clean Prod 83:33–47. https://doi.org/10.1016/j.jclepro.2014.07.071

Zhang YB, Li C, Dongzhou J, et al (2016) Experimental evaluation of MoS2 nanoparticles in jet MQL grinding with different types of vegetable oil as base oil

Rudyak VY, Krasnolutskii SL (2014) Dependence of the viscosity of nanofluids on nanoparticle size and material. Phys Lett A 378:1845–1849. https://doi.org/10.1016/j.physleta.2014.04.060

Zhang Y, Li C, Jia D et al (2016) Experimental study on the effect of nanoparticle concentration on the lubricating property of nanofluids for MQL grinding of Ni-based alloy. J Mater Process Technol 232:100–115. https://doi.org/10.1016/j.jmatprotec.2016.01.031

King RI, Hahn RS, Devereux OF (2009) Handbook of modern grinding technology. J Eng Mater Technol. https://doi.org/10.1115/1.3225989

Dai W, Kheireddin B, Gao H, Liang H (2016) Roles of nanoparticles in oil lubrication. Tribol Int 102:88–98. https://doi.org/10.1016/J.TRIBOINT.2016.05.020

Sinha MK, Madarkar R, Ghosh S, Rao PV (2017) Application of eco-friendly nanofluids during grinding of Inconel 718 through small quantity lubrication. J Clean Prod 141:1359–1375. https://doi.org/10.1016/j.jclepro.2016.09.212

Sato BK, Rodriguez RL, Talon AG, Lopes JC, Mello HJ, Aguiar PR, Bianchi EC (2019) Grinding performance of AISI D6 steel using CBN wheel vitrified and resinoid bonded. Int J Adv Manuf Technol 105:2167–2182. https://doi.org/10.1007/s00170-019-04407-5

Rodriguez RL, Lopes JC, Mancini SD, Ângelo Sanchez LE, Almeida Varasquim FMF, Volpato RS, Mello HJ, Aguiar PR, Bianchi EC (2019) Contribution for minimization the usage of cutting fluids in CFRP grinding. Int J Adv Manuf Technol 103:487–497. https://doi.org/10.1007/s00170-019-03529-0

Silva LR, Corrêa ECS, Brandão JR, de Ávila RF (2013) Environmentally friendly manufacturing: behavior analysis of minimum quantity of lubricant - MQL in grinding process. J Clean Prod. https://doi.org/10.1016/j.jclepro.2013.01.033

Benedicto E, Carou D, Rubio EM (2017) Technical, economic and environmental review of the lubrication/cooling systems used in machining processes. Procedia Eng 184:99–116. https://doi.org/10.1016/j.proeng.2017.04.075

Reddy PP, Ghosh A (2014) Effect of cryogenic cooling on spindle power and G-ratio in grinding of hardened bearing steel. Procedia Mater Sci 5:2622–2628. https://doi.org/10.1016/j.mspro.2014.07.523

Chaudhari A, Soh ZY, Wang H, Kumar AS (2018) Rehbinder effect in ultraprecision machining of ductile materials. Int J Mach Tools Manuf 133:47–60. https://doi.org/10.1016/j.ijmachtools.2018.05.009

Hadad MJ, Emami M, Sadeghi MH et al (2010) An investigation on surface grinding of AISI 4140 hardened steel using minimum quantity lubrication-MQL technique. Int J Mater Form 3:241–251

Zhang D, Li C, Zhang Y et al (2015) Experimental research on the energy ratio coefficient and specific grinding energy in nanoparticle jet MQL grinding. Int J Adv Manuf Technol 78:1275–1288. https://doi.org/10.1007/s00170-014-6722-6

de Martini FL, Lopes JC, Ribeiro FSF et al (2019) Thermal model for surface grinding application. Int J Adv Manuf Technol 104:2783–2793. https://doi.org/10.1007/s00170-019-04101-6

Brinksmeier E, Meyer D, Huesmann-Cordes AG, Herrmann C (2015) Metalworking fluids - mechanisms and performance. CIRP Ann - Manuf Technol 64:605–628. https://doi.org/10.1016/j.cirp.2015.05.003

Sinha MK, Setti D, Ghosh S, Venkateswara Rao P (2016) An investigation on surface burn during grinding of Inconel 718. J Manuf Process 21:124–133. https://doi.org/10.1016/j.jmapro.2015.12.004

Acknowledgements

The authors thank companies Nikkon Ferramentas de Corte Ltda-Saint Gobain Group for providing the grinding wheel and ITW Chemical Products for the donation of cutting fluids. The authors thank everyone who support the research and opportunity for scientific and technological development.

Funding

The São Paulo Research Foundation (FAPESP–grant number 2016/23910-0, 2017/19209-8 and 2018/22661-2), Coordination for the Improvement of Higher Level Education Personnel (CAPES) and National Council for Scientific and Technological Development (CNPq) financially supported this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lopes, J.C., Garcia, M.V., Volpato, R.S. et al. Application of MQL technique using TiO2 nanoparticles compared to MQL simultaneous to the grinding wheel cleaning jet. Int J Adv Manuf Technol 106, 2205–2218 (2020). https://doi.org/10.1007/s00170-019-04760-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04760-5