Abstract

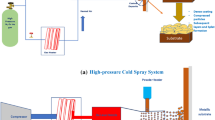

This paper presents a review of recent research inventions in the field of supersonic particle deposition (SPD) additive manufacturing (AM) technology. The SPD, also known as cold spray, is a coating technique that has gained popularity recently because of its ability to apply multi-component coatings. The SPD has the potential to revolutionize the global parts manufacturing and logistics landscape. The state-of-the-art, rapidly emerging cold spray manufacturing technology is an alternative to traditional additive manufacturing (AM) based on powder melting. It enables the rapid fabrication of parts that have properties similar to the parts developed by conventional manufacturing. In this paper, the history and process of SPD are explained. A broad background of metallic SPD AM is provided. SPD parameters, including substrate and particle properties, are discussed. Common challenges in creating consistent SPD coatings as well as challenges specific to metal and ceramic SPD are discussed. This paper explores the material science, processes, and performance gain. Several applications of SPD, including nuclear, aerospace, and electrical industries, are discussed.

Similar content being viewed by others

References

Zhou HX, Li CX, Ji G, Fu SL, Yang H, Luo XT, Yang GJ, Li CJ (2018) Local microstructure inhomogeneity and gas temperature effect in in-situ shot-peening assisted cold-sprayed Ti-6Al-4V coating. J Alloys Compd 766:694–704. https://doi.org/10.1016/j.jallcom.2018.07.009

Stoltenhoff T, Kreye H, Richter HJ (2002) An analysis of the cold spray process and its coatings. J Therm Spray Technol 11(4):542–550. https://doi.org/10.1361/105996302770348682

Assadi H, Kreye H, Gartner F, Klassen T (2016) Cold spraying - a materials perspective. Acta Mater 116:382–407. https://doi.org/10.1016/j.actamat.2016.06.034

Sova A, Maestracci R, Jeandin M, Bertrand P, Smurov I (2017) Kinetics of composite coating formation process in cold spray: modelling and experimental validation. Surf Coat Technol 318:309–314. https://doi.org/10.1016/j.surfcoat.2016.06.084

Borchers C, Gartner F, Stoltenhoff T, Assadi H, Kreye H (2003) Microstructural and macroscopic properties of cold sprayed copper coatings. J Appl Phys 93(12):10064–10070. https://doi.org/10.1063/1.1573740

Dosta S, Bolelli G, Candeli A, Lusvarghi L, Cano IG, Guilemany JM (2017) Plastic deformation phenomena during cold spray impact of WC-Co particles onto metal substrates. Acta Mater 124:173–181. https://doi.org/10.1016/j.actamat.2016.11.010

Vilardell AM, Cinca N, Dosta S, Cano IG, Guilemany JM (2019) Feasibility of using low pressure cold gas spray for the spraying of thick ceramic hydroxyapatite coatings. Int J Appl Ceram Technol 16(1):221–229. https://doi.org/10.1111/ijac.13088

Meng FC, Hu DY, Gao Y, Yue S, Song J (2016) Cold-spray bonding mechanisms and deposition efficiency prediction for particle/substrate with distinct deformability. Mater Des 109:503–510. https://doi.org/10.1016/j.matdes.2016.07.103

Moridi A, Hassani-Gangaraj SM, Guagliano M, Dao M (2014) Cold spray coating: review of material systems and future perspectives. Surf Eng 30(6):369–U329. https://doi.org/10.1179/1743294414y.0000000270

Villa M, Dosta S, Guilemany JM (2013) Optimization of 316L stainless steel coatings on light alloys using cold gas spray. Surf Coat Technol 235:220–225. https://doi.org/10.1016/j.surfcoat.2013.07.036

Brewer LN, Schiel JF, Menon ESK, Woo DJ (2018) The connections between powder variability and coating microstructures for cold spray deposition of austenitic stainless steel. Surf Coat Technol 334:50–60. https://doi.org/10.1016/j.surfcoat.2017.10.082

Spencer K, Luzin V, Matthews N, Zhang MX (2012) Residual stresses in cold spray Al coatings: the effect of alloying and of process parameters. Surf Coat Technol 206(19-20):4249–4255. https://doi.org/10.1016/j.surfcoat.2012.04.034

Dean SW, Potter JK, Yetter RA, Eden TJ, Champagne V, Trexler M (2013) Energetic intermetallic materials formed by cold spray. Intermetallics 43:121–130. https://doi.org/10.1016/j.intermet.2013.07.019

Schmidt T, Gartner F, Assadi H, Kreye H (2006) Development of a generalized parameter window for cold spray deposition. Acta Mater 54(3):729–742. https://doi.org/10.1016/j.actamat.2005.10.005

Moridi A, Hassani-Gangaraj SM, Guagliano M (2013) A hybrid approach to determine critical and erosion velocities in the cold spray process. Appl Surf Sci 273:617–624. https://doi.org/10.1016/j.apsusc.2013.02.089

Schmidt T, Assadi H, Gartner F, Richter H, Stoltenhoff T, Kreye H, Klassen T (2009) From particle acceleration to impact and bonding in cold spraying. J Therm Spray Technol 18(5-6):794–808. https://doi.org/10.1007/s11666-009-9357-7

Jenkins R, Yin S, Aldwell B, Meyer M, Lupoi R (2018) New insights into the in-process densification mechanism of cold spray Al coatings: low deposition efficiency induced densification. J Mater Sci Technol

Xiong YM, Bae G, Xiong X, Lee C (2010) The effects of successive impacts and cold welds on the deposition onset of cold spray coatings. J Therm Spray Technol 19(3):575–585. https://doi.org/10.1007/s11666-009-9455-6

Wang XM, Feng F, Klecka MA, Mordasky MD, Garofano JK, El-Wardany T, Nardi A, Champagne VK (2015) Characterization and modeling of the bonding process in cold spray additive manufacturing. Additive Manufacturing 8:149–162. https://doi.org/10.1016/j.addma.2015.03.006

Ajdelsztajn L, Jodoin B, Kim GE, Schoenung JM (2005) Cold spray deposition of nanocrystalline aluminum alloys. Metallurgical and Materials Transactions a-Physical Metallurgy and Materials Science 36A(3):657–666. https://doi.org/10.1007/s11661-005-0182-4

Liu JC, Cui H, Zhou XL, Wu XK, Zhang JS (2012) Nanocrystalline copper coatings produced by cold spraying. Met Mater Int 18(1):121–128. https://doi.org/10.1007/s12540-012-0014-1

Ito K, Ichikawa Y (2019) Microstructure control of cold-sprayed pure iron coatings formed using mechanically milled powder. Surf Coat Technol 357:129–139. https://doi.org/10.1016/j.surfcoat.2018.10.016

Ajdelsztajn L, Jodoin B, Schoenung JM (2006) Synthesis and mechanical properties of nanocrystalline Ni coatings produced by cold gas dynamic spraying. Surf Coat Technol 201(3-4):1166–1172. https://doi.org/10.1016/j.surfcoat.2006.01.037

Rokni MR, Widener CA, Crawford GA, West MK (2015) An investigation into microstructure and mechanical properties of cold sprayed 7075 Al deposition. Materials Science and Engineering a-Structural Materials Properties Microstructure and Processing 625:19–27. https://doi.org/10.1016/j.msea.2014.11.059

Luo XT, Yao ML, Ma N, Takahashi M, Li CJ (2018) Deposition behavior, microstructure and mechanical properties of an in-situ micro-forging assisted cold spray enabled additively manufactured Inconel 718 alloy. Mater Des 155:384–395. https://doi.org/10.1016/j.matdes.2018.06.024

Cho SC, Takagi K, Kwon H, Seo D, Ogawa K, Kikuchi K, Kawasaki A (2012) Multi-walled carbon nanotube-reinforced copper nanocomposite coating fabricated by low-pressure cold spray process. Surf Coat Technol 206(16):3488–3494. https://doi.org/10.1016/j.surfcoat.2012.02.021

Cong DL, Li ZS, He QB, Chen HB, Zhao ZP, Zhang LP, Wu HL (2017) Wear behavior of corroded Al-Al2O3 composite coatings prepared by cold spray. Surf Coat Technol 326:247–254. https://doi.org/10.1016/j.surfcoat.2017.07.063

Zhang YY, Epshteyn Y, Chromik RR (2018) Dry sliding wear behaviour of cold-sprayed Cu-MoS2 and Cu-MoS2-WC composite coatings: the influence of WC. Tribol Int 123:296–306. https://doi.org/10.1016/j.triboint.2017.12.015

Alidokht SA, Manimunda P, Vo P, Yue S, Chromik RR (2016) Cold spray deposition of a Ni-WC composite coating and its dry sliding wear behavior. Surf Coat Technol 308:424–434. https://doi.org/10.1016/j.surfcoat.2016.09.089

Tariq NH, Gyansah L, Wang JQ, Qiu X, Feng B, Siddique MT, Xiong TY (2018) Cold spray additive manufacturing: a viable strategy to fabricate thick B4C/Al composite coatings for neutron shielding applications. Surf Coat Technol 339:224–236. https://doi.org/10.1016/j.surfcoat.2018.02.007

Petrackova K, Kondas J, Guagliano M (2018) Fixing a hole (with cold spray). Int J Fatigue 110:144–152. https://doi.org/10.1016/j.ijfatigue.2018.01.014

Kumar S, Bae G, Lee C (2016) Influence of substrate roughness on bonding mechanism in cold spray. Surf Coat Technol 304:592–605. https://doi.org/10.1016/j.surfcoat.2016.07.082

Yin S, Yan XC, Chen CY, Jenkins R, Liu M, Lupoi R (2018) Hybrid additive manufacturing of Al-Ti6Al4V functionally graded materials with selective laser melting and cold spraying. J Mater Process Technol 255:650–655. https://doi.org/10.1016/j.jmatprotec.2018.01.015

Qiu X, Tariq NU, Wang JQ, Tang JR, Gyansah L, Zhao ZP, Xiong TY (2018) Microstructure, microhardness and tribological behavior of Al2O3 reinforced A380 aluminum alloy composite coatings prepared by cold spray technique. Surf Coat Technol 350:391–400. https://doi.org/10.1016/j.surfcoat.2018.07.039

Lek JY, Bhowmik A, Tan AWY, Sun W, Song X, Zhai W, Buenconsejo PJ, Li F, Liu EJ, Lam YM, Boothroyd CB (2018) Understanding the microstructural evolution of cold sprayed Ti-6Al-4V coatings on Ti-6Al-4V substrates. Appl Surf Sci 459:492–504. https://doi.org/10.1016/j.apsusc.2018.07.175

Ajaja J, Goldbaum D, Chromik RR (2011) Characterization of Ti cold spray coatings by indentation methods. Acta Astronautica 69(11-12):923–928. https://doi.org/10.1016/j.actaastro.2011.06.012

Faizan-Ur-Rab M, Zahiri SH, Masood SH, Phan TD, Jahedi M, Nagarajah R (2016) Application of a holistic 3D model to estimate state of cold spray titanium particles. Mater Des 89:1227–1241. https://doi.org/10.1016/j.matdes.2015.10.075

Arabgol Z, Vidaller MV, Assadi H, Gartner F, Klassen T (2017) Influence of thermal properties and temperature of substrate on the quality of cold-sprayed deposits. Acta Mater 127:287–301. https://doi.org/10.1016/j.actamat.2017.01.040

King PC, Busch C, Kittel-Sherri T, Jahedi M, Gulizia S (2014) Interface melding in cold spray titanium particle impact. Surf Coat Technol 239:191–199. https://doi.org/10.1016/j.surfcoat.2013.11.039

Hussain T, McCartney DG, Shipway PH, Zhang D (2009) Bonding mechanisms in cold spraying: the contributions of metallurgical and mechanical components. J Therm Spray Technol 18(3):364–379. https://doi.org/10.1007/s11666-009-9298-1

Xie YC, Yin S, Chen CY, Planche MP, Liao HL, Lupoi R (2016) New insights into the coating/substrate interfacial bonding mechanism in cold spray. Scr Mater 125:1–4. https://doi.org/10.1016/j.scriptamat.2016.07.024

Nikbakht R, Seyedein SH, Kheirandish S, Assadi H, Jodoin B (2018) Asymmetrical bonding in cold spraying of dissimilar materials. Appl Surf Sci 444:621–632. https://doi.org/10.1016/j.apsusc.2018.03.103

Gartner F, Stoltenhoff T, Schmidt T, Kreye H (2006) The cold spray process and its potential for industrial applications. J Therm Spray Technol 15(2):223–232. https://doi.org/10.1361/105996306x108110

Leitz KH, O'Sullivan M, Plankensteiner A, Kestler H, Sigl LS (2018) OpenFOAM modeling of particle heating and acceleration in cold spraying. J Therm Spray Technol 27(1-2):135–144. https://doi.org/10.1007/s11666-017-0644-4

Li YJ, Luo XT, Rashid H, Li CJ (2018) A new approach to prepare fully dense Cu with high conductivities and anti-corrosion performance by cold spray. J Alloys Compd 740:406–413. https://doi.org/10.1016/j.jallcom.2017.11.053

Winnicki M, Malachowska A, Piwowarczyk T, Rutkowska-Gorczyca M, Ambroziak A (2016) The bond strength of Al + Al2O3 cermet coatings deposited by low-pressure cold spraying. Arch Civil Mech Eng 16(4):743–752. https://doi.org/10.1016/j.acme.2016.04.014

Malachowska A, Winnicki M, Konat L, Piwowarczyk T, Pawlowski L, Ambroziak A, Stachowicz M (2017) Possibility of spraying of copper coatings on polyamide 6 with low pressure cold spray method. Surf Coat Technol 318:82–89. https://doi.org/10.1016/j.surfcoat.2017.02.001

Feng Y, Li WY, Guo CW, Gong MJ, Yang K (2018) Mechanical property improvement induced by nanoscaled deformation twins in cold-sprayed Cu coatings. Materials Science and Engineering a-Structural Materials Properties Microstructure and Processing 727:119–122. https://doi.org/10.1016/j.msea.2018.04.113

Lee YTR, Ashrafizadeh H, Fisher G, McDonald A (2017) Effect of type of reinforcing particles on the deposition efficiency and wear resistance of low-pressure cold-sprayed metal matrix composite coatings. Surf Coat Technol 324:190–200. https://doi.org/10.1016/j.surfcoat.2017.05.057

Huang CJ, Li WY, Xie YC, Planche MP, Liao HL, Montavon G (2017) Effect of substrate type on deposition behavior and wear performance of ni-coated graphite/al composite coatings deposited by cold spraying. J Mater Sci Technol 33(4):338–346. https://doi.org/10.1016/j.jmst.2016.11.016

Kumar S, Reddy SK, Joshi SV (2017) Microstructure and performance of cold sprayed Al-SiC composite coatings with high fraction of particulates. Surf Coat Technol 318:62–71. https://doi.org/10.1016/j.surfcoat.2016.11.047

Na H, Bae G, Shin S, Kumar S, Kim H, Lee C (2009) Advanced deposition characteristics of kinetic sprayed bronze/diamond composite by tailoring feedstock properties. Compos Sci Technol 69(3-4):463–468. https://doi.org/10.1016/j.compscitech.2008.11.015

Kwon H, Cho S, Kawasaki A (2015) Diamond-reinforced metal matrix bulk materials fabricated by a low-pressure cold-spray process. Mater Trans 56 (1):108-112. doi:https://doi.org/10.2320/matertrans.M2014145

Tang J, Saha GC, Richter P, Kondas J, Colella A, Matteazzi P (2018) Effects of post-spray heat treatment on hardness and wear properties of Ti-WC high-pressure cold spray coatings. J Therm Spray Technol 27(7):1153–1164. https://doi.org/10.1007/s11666-018-0762-7

Peat T, Galloway A, Toumpis A, McNutt P, Iqbal N (2017) The erosion performance of particle reinforced metal matrix composite coatings produced by co-deposition cold gas dynamic spraying. Appl Surf Sci 396:1623–1634. https://doi.org/10.1016/j.apsusc.2016.10.155

Ji GC, Wang HT, Chen X, Bai XB, Dong ZX, Yang FG (2013) Characterization of cold-sprayed multimodal WC-12Co coating. Surf Coat Technol 235:536–543. https://doi.org/10.1016/j.surfcoat.2013.08.021

Yandouzi M, Bu H, Brochu M, Jodoin B (2012) Nanostructured Al-based metal matrix composite coating production by pulsed gas dynamic spraying process. J Therm Spray Technol 21(3-4):609–619. https://doi.org/10.1007/s11666-011-9727-9

Al-Hamdani KS, Murray JW, Hussain T, Kennedy A, Clare AT (2017) Cold sprayed metal-ceramic coatings using satellited powders. Mater Lett 198:184–187. https://doi.org/10.1016/j.matlet.2017.03.175

Sova A, Kosarev V, Papyrin A, Smurov I (2011) Effect of ceramic particle velocity on cold spray deposition of metal-ceramic coatings. J Therm Spray Technol 20(1-2):285–291. https://doi.org/10.1007/s11666-010-9571-3

Bakshi SR, Singh V, Balani K, McCartney DG, Seal S, Agarwal A (2008) Carbon nanotube reinforced aluminum composite coating via cold spraying. Surf Coat Technol 202(21):5162–5169. https://doi.org/10.1016/j.surfcoat.2008.05.042

Bagherifard S, Monti S, Zuccoli MV, Riccio M, Kondas J, Guagliano M (2018) Cold spray deposition for additive manufacturing of freeform structural components compared to selective laser melting. Materials Science and Engineering a-Structural Materials Properties Microstructure and Processing 721:339–350. https://doi.org/10.1016/j.msea.2018.02.094

Yang K, Li WY, Guo XP, Yang XW, Xu YX (2018) Characterizations and anisotropy of cold-spraying additive-manufactured copper bulk. J Mater Sci Technol 34(9):1570–1579. https://doi.org/10.1016/j.jmst.2018.01.002

Jing Z, Dejun K (2018) Effect of laser remelting on microstructure and immersion corrosion of cold-sprayed aluminum coating on S355 structural steel. Opt Laser Technol 106:348–356. https://doi.org/10.1016/j.optlastec.2018.04.026

Daroonparvar R, Kay CM, Karthikeyan J (2018) Modified bond coatings improve service life of plasma sprayed thermal barrier coatings and protective performance of overlay coatings. Adv Mater Process 176(5):40–43

Cormier Y, Dupuis P, Jodoin B, Corbeil A (2015) Mechanical properties of cold gas dynamic-sprayed near-net-shaped fin arrays. J Therm Spray Technol 24(3):476–488. https://doi.org/10.1007/s11666-014-0203-1

Pattison J, Celotto S, Morgan R, Bray M, O'Neill W (2007) Cold gas dynamic manufacturing: a non-thermal approach to freeform fabrication. Int J Mach Tool Manu 47(3-4):627–634. https://doi.org/10.1016/j.ijmachtools.2006.05.001

Lynch M, Gu W, El-Wardany T, Hsu A, Viens D, Nardi A, Klecka M (2013) Design and topology/shape structural optimization for additively manufactured cold sprayed components. Virtual Phys Prototy 8:213–231. https://doi.org/10.1080/17452759.2013.837629

Sova A, Grigoriev S, Okunkova A, Smurov I (2013) Potential of cold gas dynamic spray as additive manufacturing technology. Int J Adv Manuf Technol 69(9-12):2269–2278. https://doi.org/10.1007/s00170-013-5166-8

High Pressure Cold Spray: Principles and Applications (2016). ASM International,

Li WY, Li CJ, Liao HL (2006) Effect of annealing treatment on the microstructure and properties of cold-sprayed Cu coating. J Therm Spray Technol 15(2):206–211. https://doi.org/10.1361/105996306x108066

Yin S, Cavaliere P, Aldwell B, Jenkins R, Liao HL, Li WY, Lupoi R (2018) Cold spray additive manufacturing and repair: fundamentals and applications. Additive Manufacturing 21:628–650. https://doi.org/10.1016/j.addma.2018.04.017

Yoon SH, Lee C, Kim HJ Process development of brazed aluminum heat exchanger using a kinetic spraying process. In: International Thermal Spray Conference, Beijing, China, 2007. Global Coating Solutions. ASM International, p 1180

Bobzin K, Öte M, Linke TF, Aachen R Integration of electrical functionality by transplantation of cold sprayed electrical conductive Cu tracks via injection moulding. In: International Thermal Spray Conference, Barcelona, Spain, 2014. ASM International, p 6

Murray JW, Zuccoli MV, Hussain T (2018) Heat treatment of cold-sprayed C355 Al for repair: microstructure and mechanical properties. J Therm Spray Technol 27(1-2):159–168. https://doi.org/10.1007/s11666-017-0665-z

Raoelison RN, Verdy C, Liao H (2017) Cold gas dynamic spray additive manufacturing today:deposit possibilities, technological solutions and viable applications. Mater Des 133:266-287. doi:https://doi.org/10.1016/j.matdes.2017.07.067

Tazegul O, Dylmishi V, Cimenoglu H (2016) Copper matrix composite coatings produced by cold spraying process for electrical applications. Arch Civil Mech Eng 16(3):344–350. https://doi.org/10.1016/j.acme.2016.01.005

Daroonparvar M, Yajid MAM, Kay CM, Bakhsheshi-Rad H, Gupta RK, Yusof NM, Ghandvar H, Arshad A, Zulkifli ISM (2018) Effects of Al2O3 diffusion barrier layer (including Y-containing small oxide precipitates) and nanostructured YSZ top coat on the oxidation behavior of HVOF NiCoCrAlTaY/APS YSZ coatings at 1100 degrees C. Corros Sci 144:13–34. https://doi.org/10.1016/j.corsci.2018.07.013

Huang C, Yang K, Li N, Li W, Planche M, Verdy C, Liao H, Montavon G (2018) Microstructures and wear-corrosion performance of vacuum plasma sprayed and cold gas dynamic sprayed Muntz alloy coatings. Surf Coat Technol

Yin S, Ekoi EJ, Lupton TL, Dowling DP, Lupoi R (2017) Cold spraying of WC-Co-Ni coatings using porous WC-17Co powders: formation mechanism, microstructure characterization and tribological performance. Mater Des 126:305–313. https://doi.org/10.1016/j.matdes.2017.04.040

Watson TJ, Nardi A, Ernst AT, Cernatescu I, Bedard BA, Aindow M (2017) Cold spray deposition of an icosahedral-phase-strengthened aluminum alloy coating. Surf Coat Technol 324:57–63. https://doi.org/10.1016/j.surfcoat.2017.05.049

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Monette, Z., Kasar, A.K., Daroonparvar, M. et al. Supersonic particle deposition as an additive technology: methods, challenges, and applications. Int J Adv Manuf Technol 106, 2079–2099 (2020). https://doi.org/10.1007/s00170-019-04682-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04682-2