Abstract

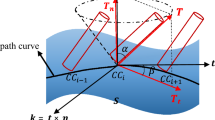

Tool orientations’ planning of five-axis machining is a significant factor for impacting surface quality and overall machining accuracy of complex-curved surface parts. This paper particularly describes a practical method of tool orientation’s generation for ball cutters commonly used in complex surface finish machining. Based on the method of triangular meshing in surface, the points and the normal vectors are respectively extracted from the surface with unknown parameters. Each obtained normal vector is translated by Rodrigues’ rotational motion in space into the tool orientation for the ball cutter. The generated tool orientation is simple to be adjusted and can effectively avoid problems such as overcut and interference during machining. In addition, by analyzing the nonlinear error between adjacent tool orientations in machining, an interpolation is proposed approach to reduce the rotational error angle and guarantee the continuity of trajectory. After actual processing, the highlights of this method are verified.

Similar content being viewed by others

References

He W, Lei M, Bin H (2008) Iso-parametric CNC tool path optimization based on adaptive grid generation. Int J Adv Manuf Technol 41(5-6):538–548

Ding S, Mannan M, Poo A, Yang D, Han Z (2003) Adaptive iso-planar tool path generation for machining of free-form surfaces. Comput Aided Des 35(2):141–153

Can A, Unüvar A (2010) A novel iso-scallop tool-path generation for efficient five-axis machining of free-form surfaces. Int J Adv Manuf Technol 51(9-12):1083–1098

Li X, Lee C, Hu P, Zhang Y, Yang F (2017) Cutter partition-based tool orientation optimization for gouge avoidance in five-axis machining. Int J Adv Manuf Technol 95(5-8):2041–2057

Kim Y, Elber G, Bartoň M, Pottmann H (2015) Precise gouging-free tool orientations for 5-axis CNC machining. Comput Aided Des 58:220–229

Mi Z, Yuan C, Ma X, Shen L (2016) Tool orientation optimization for 5-axis machining with C-space method. Int J Adv Manuf Technol 88(5-8):1243–1255

Castagnetti C, Duc E, Ray P (2008) The domain of admissible orientation concept: a new method for five-axis tool path optimisation. Comput Aided Des 40(9):938–950

Lavernhe S, Tournier C, Lartigue C (2008) Optimization of 5-axis high-speed machining using a surface based approach. Comput Aided Des 40(10-11):1015–1023

Hu P, Chen L, Tang K (2017) Efficiency-optimal iso-planar tool path generation for five-axis finishing machining of freeform surfaces. Comput Aided Des 83:33–50

Lin Z, Fu J, Yao X, Sun Y (2015) Improving machined surface textures in avoiding five-axis singularities considering tool orientation angle changes. Int J Mach Tools Manuf 98:41–49

Sun C, Altintas Y (2016) Chatter free tool orientations in 5-axis ball-end milling. Int J Mach Tools Manuf 106:89–97

Kim H (2008) Tool path generation for contour parallel milling with incomplete mesh model. Int J Adv Manuf Technol 48(5-8):443–454

Sun Y, Guo D, Jia Z, Wang H (2005) Iso-parametric tool path generation from triangular meshes for free-form surface machining. Int J Adv Manuf Technol 28(7-8):721–726

Qiu L, Song A, Sun J, Shen Y, Peng Y (2016) A three-dimensional spiral smooth machining path based on the expansion surface. Int J Adv Manuf Technol 89(5-8):1615–1621

Zhang K, Tang K (2014) An efficient greedy strategy for five-axis tool path generation on dense triangular mesh. Int J Adv Manuf Technol 74(9-12):1539–1550

Wang Q, Feng Y, Gao Y, Li Z, Tan J (2018) Smooth fillet-end cutter tool path generation method on triangular-mesh surface based on Modified Butterfly subdivision. Int J Adv Manuf Technol 98(9-12):2831–2847

Zhou Y, Zhou J, Zhou YF, Zhan F (1999) Analysis and control of the theoretical errors in five axis NC machining. J Mech Eng 35(5):54–57

Wu D, Wang Y, Feng J, Yang J (2007) Analysis and control of the non-linear errors in five-axis NC machining. J Shanghai Jiaotong Univ 41(10):1608–1612

Fan L, Qi D, Shen B, Zhu Z (2011) Plane interpolation of tool orientation algorithm for 5-axis circumference milling. J Mech Eng 47(19):158–162

Ho M, Hwang Y, Hu C (2003) Five-axis tool orientation smoothing using quaternion interpolation algorithm. Int J Mach Tools Manuf 43(12):1259–1267

Liu F, Wang L, Hu J, Yao Z (2009) A new spatial arc interpolation method using quaternion interpolation algorithm. Mech Sci Technol 28(11):1425–1428

Yang X, Zhou Y, Chen Z, Wang F (2012) Analysis and control of tool path interpolation error in rotary axes motions of five-axis CNC milling. J Mech Eng 48(3):140–146

Xu D, Qin H, Zhou H (2016) CNC machining tool path planning based in triangular mesh surface mapping. Comput Integr Manuf Syst 22(10):2371–2379

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. 51635003), and the Postgraduate Research & Practice Innovation Program of Jiangsu Province (Grant No.KYCX18_1092).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hong, X., Hong, R. & Lin, X. Tool orientations’ generation and nonlinear error control based on complex surface meshing. Int J Adv Manuf Technol 105, 4279–4288 (2019). https://doi.org/10.1007/s00170-019-04480-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04480-w