Abstract

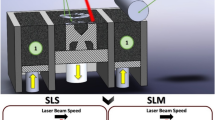

Because the selective laser melting (SLM) formation process involves rapid melting and solidification of slices, the SLM process places high demands on the tightness, uniformity, and flatness of the powder layer. Based on the discrete element method (particle contact force model, particle collision judgment algorithm, and particle motion equation) and the SLM laying powder process, a numerical simulation of the SLM laying powder process was carried out. For the performance measurement experiment of the TC4 titanium alloy powder, the powder bulk density, tap density, and angle of repose were calculated and analyzed. It was found that the tap density increased by 7.5% compared to the bulk density, and the calculated average angle of repose (32.6°) was in good agreement with the experimental data (33.2°), thus verifying the accuracy of the calculation model used for the SLM laying powder. The influences of different scraping methods and scraping speeds on the quality of the laying powder were calculated and analyzed. It was found that the scraping method using a roller (not rotating) obtained the highest tightness and most uniform powder distribution, and, as the scraping speed increased, the laying tightness tended to decrease linearly. The results of the numerical simulation study of the SLM laying powder process can be used to guide the actual SLM laying powder process and, alternatively, provide basic data for the numerical simulation of SLM molten pool dynamics based on the particle scale.

Similar content being viewed by others

Abbreviations

- m e :

-

Equivalent mass of particle i and particle j

- u n, u t :

-

Normal and tangential relative displacements of the particles, respectively

- t :

-

Time

- D n, D t :

-

Normal and tangential damping coefficients of the contact model, respectively

- E n, E t :

-

Normal and tangential elastic coefficients of the contact model, respectively

- F n, F t :

-

Normal and tangential components of the particle contact force, respectively

- I e :

-

Equivalent moment of inertia of the particle

- θ :

-

Rotation angle of the particle itself

- r :

-

Radius of rotation

- M :

-

External torque of the particles

- μ :

-

Coefficient of friction of the particles

- sgn:

-

A symbolic function

- \( \tilde{P} \) :

-

Created box for the particle P

- L ij :

-

Spherical center distance between particle i and particle j

- r i, r j :

-

Radius of particle i and particle j, respectively

- m i :

-

Mass of particle i

- \( {\ddot{\boldsymbol{u}}}_i \) :

-

Acceleration of particle i

- F sum :

-

External force of the particle i at the centroid

- I i :

-

Moment of inertia of particle i

- \( {\ddot{\theta}}_i \) :

-

Angular acceleration of particle i

- M sum :

-

External moment of the particle i at the centroid

- \( {\left({\dot{\boldsymbol{u}}}_i\right)}_N \) :

-

Particle velocity of the next time step

- \( {\left({\dot{\theta}}_i\right)}_N \) :

-

Angular velocity of the next time step

- Δt :

-

Time step

References

Shipley H, McDonnell D, Culleton M, Coull R, Lupoi R, O’Donnell G (2018) Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V: a review. Int J Mach Tool Manu 128:1–20

Yang YQ, Chen J, Song CH, Wang D, Bai YC (2018) Current status and progress on technology of selective laser melting of metal parts. Laser Optoelectron Progress 55(1):011401

Gao ZJ, Zhou XL, Li JH, Zhang GJ (2018) A review: high-performance spherical metal powder preparation methods. Therm Spray Technol 10(3):1–9

Xia MJ, Gu DD, Yu GQ, Dai DH, Chen HY, Shi QM (2017) Porosity evolution and its thermodynamic mechanism of randomly packed powder-bed during selective laser melting of Inconel 718 alloy. Int J Mach Tool Manu 116:96–106

Cao L, Sun F, Chen T, Tang YL, Liao DM (2018) Quantitative prediction of oxide inclusion defects inside the casting and on the walls during cast-filling processes. Int J Heat Mass Transf 119:614–623

Cao L, Liao DM, Sun F, Chen T (2018) Numerical simulation of cold-lap defects during casting filling process. Int J Adv Manuf Technol 97:2419–2430

Xiao B, Zhang Y (2007) Marangoni and buoyancy effects on direct metal laser sintering with a moving laser beam. Numer Heat Transf A Appl 51(8):715–733

Dai D, Gu DD (2014) Thermal behavior and densification mechanism during selective laser melting of copper matrix composites: simulation and experiments. Mater Des 55:482–491

Michaleris P (2014) Modeling metal deposition in heat transfer analyses of additive manufacturing processes. Finite Elem Anal Des 86:51–60

Lee YS, Zhang W (2015) Mesoscopic simulation of heat transfer and fluid flow in laser powder bed additive manufacturing. Annual International Solid Freeform Fabrication Symposium 1154-1165

Gürtler FJ, Karg M, Leitz KH, Schmidt M (2013) Simulation of laser beam melting of steel powders using the three-dimensional volume of fluid method. Phys Procedia 41(1):874–879

Khairallah SA, Anderson AT, Rubenchik A, King WE (2016) Laser powder-bed fusion additive manufacturing: physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater 108:36–45

Gusarov AV, Smurov I (2010) Modeling the interaction of laser radiation with powder bed at selective laser melting. Phys Procedia 5:381–394

Yuan P, Gu DD (2015) Molten pool behaviour and its physical mechanism during selective laser melting of TiC/AlSi10Mg nanocomposites: simulation and experiments. J Phys D Appl Phys 48(3):035303

Khairallah SA, Anderson A (2014) Mesoscopic simulation model of selective laser melting of stainless steel powder. J Mater Process Technol 214(11):2627–2636

Panwisawas C, Qiu C, Anderson MJ, Sovani Y, Turner RP, Attallah MM (2017) Mesoscale modelling of selective laser melting: thermal fluid dynamics and microstructural evolution. Comput Mater Sci 126:479–490

Gürtler FJ, Karg M, Dobler M, Kohl S, Tzivilsky I, Schmidt M (2014) Influence of powder distribution on process stability in laser beam melting: analysis of melt pool dynamics by numerical simulations. Annual International Solid freeform fabrication symposium 1099-1117

Ammer R, Markl M, Ljungblad U, Körner C, Rüde U (2014) Simulating fast electron beam melting with a parallel thermal free surface lattice Boltzmann method. Comput Math Appl 67(2):318–330

Panwisawas C, Qiu CL, Sovani Y, Brooks JW, Attallah MM, Basoalto HC (2015) On the role of thermal fluid dynamics into the evolution of porosity during selective laser melting. Scr Mater 105:14–17

Markl M, Körner C (2016) Multiscale modeling of powder bed-based additive manufacturing. Annu Rev Mater Res 46:93–123

Parteli EJR, Pöschel T (2016) Particle-based simulation of powder application in additive manufacturing. Powder Technol 288:96–102

Yan W, Ge W, Qian Y, Lin S, Zhou B, Liu WK (2017) Multi-physics modeling of single/multiple-track defect mechanisms in electron beam selective melting. Acta Mater 134:324–333

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Geotechnique 29(1):47–65

Hubbard PM (1996) Approximating polyhedra with spheres for time-critical collision detection. ACM Trans Graph 15(3):179–210

Albaba A, Lambert S, Nicot F, Chareyre B (2015) Relation between microstructure and loading applied by a granular flow to a rigid wall using DEM modeling. Granul Matter 17(5):603–616

Yuan C, Chareyre B (2017) A pore-scale method for hydromechanical coupling in deformable granular media. Comput Method Appl Mech Eng 318:1066–1079

Liu BY (2018) Cyclic aging behavior of TC4 powder and the influence on properties of components built by SLM. Master Thesis, Shenyang Aerospace University

Funding

This work was supported by the Research Platform Construction Funding of Advanced Institute of Engineering Science for Intelligent Manufacturing, Guangzhou University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that he has no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cao, L. Study on the numerical simulation of laying powder for the selective laser melting process. Int J Adv Manuf Technol 105, 2253–2269 (2019). https://doi.org/10.1007/s00170-019-04440-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04440-4