Abstract

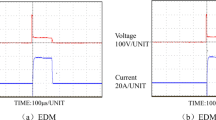

The local excessive ablation of Ti6Al4V by electrical discharge machining ablation (EDMA) is investigated in the present work. In order to achieve the high efficiency and stable ablation machining of Ti6Al4V, a method of diluting the concentration of oxygen medium by the nitrogen is proposed; that is, a mixed gas medium composed of nitrogen and oxygen is used as a gas medium for EDMA. Firstly, the effects of the oxygen concentration, discharge energy, and gas pressure on the excessive ablation of Ti6Al4V are theoretically analyzed. Then, the quantitative correlation between the above three factors and the excessive ablation phenomenon is established through the experimental exploration. Finally, the Taguchi orthogonal method is applied to systematically investigate the effects of the mentioned factors on the material removal rate (MRR) and electrode wear rate (EWR), and compared with the conventional electrical discharge machining (EDM). The experimental results show that the discharge energy and the gas pressure decrease parabolically as the oxygen concentration increases, while discharge current decreases linearly as the gas pressure increases. Moreover, the pulse width decreases exponentially as the gas pressure increases. It is observed that the discharge current and oxygen concentration have significant effects on MRR, while pulse width has significant effects on EWR. The present work shows that the processing efficiency of EDMA is more than 9 times of that for EDM with solid electrode in water.

Similar content being viewed by others

References

Arrazola PJ, Garay A, Iriarte LM, Armendia M, Marya S, Le MaîTre F (2009) Machinability of titanium alloys (Ti6Al4V and Ti555.3). J Mater Process Technol 209(5):2223–2230

Ezugwu EO (2005) Key improvements in the machining of difficult-to-cut aerospace superalloys. Int J Mach Tools Manuf 45(12–13):1353–1367

Manjaiah M, Narendranath S, Basavarajappa S (2014) A review on machining of titanium based alloys using EDM and WEDM. Rev Adv Mater Sci 36(2):89–111

Klocke F, Zeis M, Klink A, Veselovac D (2013) Technological and economical comparison of roughing strategies via milling, sinking-EDM, wire-EDM and ECM for titanium- and nickel-based blisks. CIRP J Manuf Sci Technol 6(3):198–203

Fonda P, Wang Z, Yamazaki K, Akutsu Y (2008) A fundamental study on Ti-6Al-4V’s thermal and electrical properties and their relation to EDM productivity. J Mater Process Technol 202:583–589

Hasçalık A, Çaydaş U (2007) Electrical discharge machining of Ti6Al4V. Appl Surf Sci 253(22):9007–9016

Chen SL, Yan BH, Huang FY (1999) Influence of kerosene and distilled water as dielectrics on the electric discharge machining characteristics of Ti6A14V. J Mater Process Technol 87(1–3):107–111

Wang XZ, Liu ZD, Xue RY, Tian ZJ, Huang YH (2013) Research on self-mixed oxygen in discharge gap to improve the processing characteristics of Ti6Al4V electrical discharge machining. Acta Aeronaut Astronaut Sin 34:2419–2426

Gu L, Li L, Zhao WS, Rajurkar KP (2012) Electrical discharge machining of Ti6Al4V with a bundled electrode. Int J Mach Tools Manuf 53:100–106

Kou Z, Han FZ (2018) Machining characteristics and removal mechanisms of moving electric arcs in high-speed EDM milling. J Manuf Process 32:676–684

Shen Y, Liu YH, Zhang YZ, Dong H, Sun WY, Wang XL, Zheng C, Ji RJ (2015) High-speed dry electrical discharge machining. Int J Mach Tools Manuf 93:19–25

Liu ZD, Yin CJ, Chen LH (2014) Efficient combined machining of electrospark-induced controllable combustion and turning dressing for TC4. Mater Manuf Process 29(5):614–620

Wang XZ, Liu ZD, Qiu MB, Huang YH (2014) Mechanism of electrical discharge machining ablation. Mater Manuf Process 29(11–12):1367–1373

Cao ZL, Liu ZD, Wang XZ, Qiu MB, Hui ZG (2015) Monopulse electrical discharge machining ablation drilling technology for Ti-6Al-4V Ti6Al4V. Int J Adv Manuf Technol 86(1–4):539–546

Xu AY, Liu ZD, Li WP, Tian ZJ, Qiu MB (2014) Study of high-efficiency electrical discharge machining-induced ablation machining of Ti6Al4V TC4 using a multi-function electrode. Int J Adv Manuf Technol 72:377–385

Zhao YQ, Zhou L, Qu H L, Wu H, Liu CL, Li Y L (2002) Effects of ambient air with different flow rates of N2 and O2 on combustion behavior of Ti6Al4Vs. New progress in materials science and Engineering in 2002 (Part 2) -- Proceedings of 2002 China Materials Symposium (in Chinese)

Kong LL, Liu ZD, Han YX, Qiu MB (2018) Research on the efficient and stable sinking electrical discharge machining ablation process of Ti-6Al-4V. Int J Adv Manuf Technol 12-13:1–11

Marashi H, Jafarlou DM, Sarhan AAD, Hamdi M (2016) Review article: state of the art in powder mixed dielectric for EDM applications. Precis Eng 46:11–33

Wang XZ, Liu ZD, Qiu MB, Huang YH (2014) Influence of gas pressure on EDM ablation of Ti6Al4V. Acta Aeronautica et Astronautica Sin 35(12):3480–3488

Liang GF (1975) High-speed oxygen cutting method. China Machine Press, Beijing, pp 15–16 (in Chinese)

Zhang S, Jinsong H (2006) Non-ferrous metal smelting and ingot casting. Chemical Industry Press, Beijing, pp 8–12 (in Chinese)

Kolli M, Kumar A (2015) Effect of dielectric fluid with surfactant and graphite powder on electrical discharge machining of Ti6Al4V using Taguchi method. Eng Sci Technol, Int J 18(4):S2215098615000427

Zhu G, Zhang QH, Wang H, Wang K, Zhang M (2017) Machining behaviors of short electrical arc milling with high frequency and high voltage pulses. Int J Adv Manuf Technol 90(1–4):1067–1074

Kunieda M, Miyoshi Y (1997) Electrical discharge machining in gas. Ann CIRP 46:143–146

Yan B, Tsai H, Huang F (2005) The effect in EDM of a dielectric of a urea solution in water on modifying the surface of titanium. Int J Mach Tools Manuf 45:194–200

Kibria G, Sarkar BR, Pradhan BB, Bhattacharyya B (2010) Comparative study of different dielectrics for micro-EDM performance during microhole machining of Ti6Al4V alloy. Int J Adv Manuf Technol 48(5–8):557–570

Singh S, Bhardwaj A (2011) Review to EDM by using water and powder-mixed dielectric fluid. J Miner Mater Charact Eng 10(2):199–230

Tang L, Du YT (2014) Multi-objective optimization of green electrical discharge machining Ti–6Al–4V in tap water via Grey-Taguchi method. Mater Manuf Process 29:507–513

Acknowledgments

We extend our sincere thanks to all who contributed to the preparation of this manuscript.

Funding

This work was supported by National Natural Science Foundation of China (Grant Nos. 51675272, 51575271).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kong, L., Liu, Z., Bai, S. et al. Investigation of the controllable characteristics of electrical discharge ablation of Ti6Al4V. Int J Adv Manuf Technol 105, 1645–1654 (2019). https://doi.org/10.1007/s00170-019-04399-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04399-2