Abstract

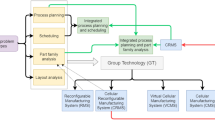

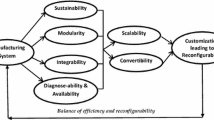

The layout is an important issue in the design of manufacturing systems. In conventional systems, the layout rarely changes after the initial design. However, as the market demands are changing more frequently, layout configurations must be capable of reconfiguring the arrangement of resources to suit new production requirements, while minimising material handling and relocation costs and maximising savings in material flow and inventory costs. This paper presents a literature review on the layout design of reconfigurable manufacturing systems (RMS), focusing on reconfigurable layouts, which have been attracting increasing attention in recent years. A systematic literature network analysis was applied to identify trends, evolutionary trajectories and key issues that are influencing the development of knowledge in this field of study. The results are analysed and discussed using a bibliometric and a chronological citation network analysis. The major findings of this research includes (1) the layout design of RMS must be integrated in the process of RMS design, which, in turn, should be considered as a cyclic process, instead of divided into phases. (2) The core characteristics of reconfigurability and the layout design cannot be dissociated. (3) Operational performance measures are rarely considered in the reconfigurable layout problem, despite their importance. (4) Optimisation approaches have been widely used to solve the reconfigurable layout problem. However, they might not be the most suitable approach to deal with the uncertainty and variability present in manufacturing environments in which reconfigurable layouts are required. Finally, this paper identifies gaps in the literature and suggests directions for future research.

Similar content being viewed by others

References

Koren Y, Gu X, Guo W (2018) Reconfigurable manufacturing systems: principles, design and future trends. Front Mech Eng 13:121–136

Koren Y, Heisel U, Jovane F et al (1999) Reconfigurable manufacturing systems. CIRP Ann Manuf Technol 48:527–540

Renzi C, Leali F, Cavazzuti M, Andrisano AO (2014) A review on artificial intelligence applications to the optimal design of dedicated and reconfigurable manufacturing systems. Int J Adv Manuf Technol 72:403–418

Hasan MA, Sarkis J, Shankar R (2012) Agility and production flow layouts: an analytical decision analysis. Comput Ind Eng 62:898–907

Wang L (2011) Alternative shop-floor re-layout design due to dynamic operation changes. In: ASME-MSEC, pp 1–7

Setchi RM, Lagos N (2004) Reconfigurability and reconfigurable manufacturing systems - state-of-the-art review. Ind Informatics, 2004 INDIN ’04 2004 2nd IEEE Int Conf, pp 529–535

Koren Y, Shpitalni M (2010) Design of reconfigurable manufacturing systems. J Manuf Syst 29:130–141

Xiaobo Z, Jiancai W, Zhenbi L (2000) A stochastic model of a reconfigurable manufacturing system part 1: a framework. Int J Prod Res 38:2273–2285

Youssef AMA, ElMaraghy HA (2008) Availability consideration in the optimal selection of multiple-aspect RMS configurations. Int J Prod Res 46:5849–5882

Saxena LK, Jain PK (2012) A model and optimisation approach for reconfigurable manufacturing system configuration design. Int J Prod Res 50:3359–3381

Dahane M, Benyoucef L (2016) An adapted NSGA-II algorithm for a reconfigurable manufacturing system (RMS) design under machines reliability constraints. In: Metaheuristics for production systems. Springer, Cham, pp 93–107

Oke A, Abou-El-Hossein K, Theron NJ (2011) The design and development of a reconfigurable manufacturing system. S Afr J Ind Eng 22:121–132

Benderbal HH, Dahane M, Benyoucef L (2017) Layout evolution effort for product family in reconfigurable manufacturing system design. IFAC-PapersOnLine 50:10166–10171

Singh SP, Sharma RRK (2006) A review of different approaches to the facility layout problems. Int J Adv Manuf Technol 30:425–433

Abbasi M, Houshmand M (2011) Production planning and performance optimization of reconfigurable manufacturing systems using genetic algorithm. Int J Adv Manuf Technol 54:373–392

Kheirkhah A, Navidi H, Bidgoli MM (2015) Dynamic facility layout problem: a new bilevel formulation and some metaheuristic solution methods. IEEE Trans Eng Manag 62:396–410

Meng G, Heragu SS, Zijm H (2004) Reconfigurable layout problem. Int J Prod Res 42:4709–4729

Benjaafar S, Heragu SS, Irani SA (2002) Next generation factory layouts: research challenges and recent progress. Interfaces (Providence) 32:58–76

Baykasoǧlu A (2003) Capability-based distributed layout approach for virtual manufacturing cells. Int J Prod Res 41:2597–2618

Baykasoǧlu A, Göçken M (2010) Capability-based distributed layout and its simulation based analyses. J Intell Manuf 21:471–485

Maganha I, Silva C (2017) A theoretical background for the reconfigurable layout problem. Procedia Manuf 11:2025–2033

Drira A, Pierreval H, Hajri-Gabouj S (2007) Facility layout problems: a survey. Annu Rev Control 31:255–267

Anjos MF, Vieira MVC (2017) Mathematical optimization approaches for facility layout problems: the state-of-the-art and future research directions. Eur J Oper Res 261:1–16

Hosseini-Nasab H, Fereidouni S, Ghomi SMTF, Fakhrzad MB (2018) Classification of facility layout problems: a review study. Int J Adv Manuf Technol 94:957–977

Askin RG (2013) Contributions to the design and analysis of cellular manufacturing systems. Int J Prod Res 51:6778–6787

Houshyar AN, Leman Z, Moghadam HP et al (2014) Literature review on dynamic cellular manufacturing system. IOP Conf Ser Mater Sci Eng 58:012016

Moslemipour G, Lee TS, Rilling D (2012) A review of intelligent approaches for designing dynamic and robust layouts in flexible manufacturing systems. Int J Adv Manuf Technol 60:11–27

Colicchia C, Strozzi F (2012) Supply chain risk management: a new methodology for a systematic literature review. Supply Chain Manag An Int J 17:403–418

Ding Y, Chowdhury GG, Foo S (2001) Bibliometric cartography of information retrieval research by using co-word analysis. Inf Process Manag 37:817–842

Fera M, Fruggiero F, Lambiase A et al (2017) The role of uncertainty in supply chains under dynamic modeling. Int J Ind Eng Comput 8:119–140

Strozzi F, Colicchia C, Creazza A, Noè C (2017) Literature review on the ‘smart factory’ concept using bibliometric tools. Int J Prod Res 55:1–20

Colicchia C, Creazza A, Noè C, Strozzi F (2019) Information sharing in supply chains: a review of risks and opportunities using the systematic literature network analysis (SLNA). Supply Chain Manag 24:5–21

Vargas SA, Esteves GRT, Maçaira PM et al (2019) Wind power generation: a review and a research agenda. J Clean Prod 218:850–870

Benderbal HH, Dahane M, Benyoucef L (2017) Flexibility-based multi-objective approach for machines selection in reconfigurable manufacturing system (RMS) design under unavailability constraints. Int J Prod Res 55:6033–6051

Nooy W, Mrvar A, Batagelj V (2011) Exploratory social network analysis with Pajek (Strucutural analysis in the social sciences; 34), 2nd ed. Cambridge University Press

Liu JS, Ly LYY (2012) An integrated approach for main path analysis: development of the Hirsch index as an example. J Am Soc Inf Sci Technol 63:528–542

Abdi MR, Labib AW (2003) A design strategy for reconfigurable manufacturing systems (RMSs) using analytical hierarchical process (AHP): a case study. Int J Prod Res 41:2273–2299

Abdi MR, Labib AW (2004) Grouping and selecting products: the design key of reconfigurable manufacturing systems (RMSs). Int J Prod Res 42:521–546

Youssef AMA, ElMaraghy HA (2006) Modelling and optimization of multiple-aspect RMS configurations. Int J Prod Res 44:4929–4958

Youssef AMA, ElMaraghy HA (2007) Optimal configuration selection for reconfigurable manufacturing systems. Int J Flex Manuf Syst 19:67–106

Dou JP, Dai X, Meng Z (2009) Graph theory-based approach to optimize single-product flow-line configurations of RMS. Int J Adv Manuf Technol 41:916–931

Dou JP, Dai X, Meng Z (2010) Optimisation for multi-part flow-line configuration of reconfigurable manufacturing system using GA. Int J Prod Res 48:4071–4100

Benderbal HH, Dahane M, Benyoucef L (2018) Modularity assessment in reconfigurable manufacturing system (RMS) design: an archived multi-objective simulated annealing-based approach. Int J Adv Manuf Technol 94:729–749

Waltman L, van Eck NJ, Noyons ECM (2010) A unified approach to mapping and clustering of bibliometric networks. J Inf Secur 4:629–635

Deif AM, ElMaraghy WH (2006) A systematic design approach for reconfigurable manufacturing systems. In: Advances in design. Springer, London, pp 219–228

Benkamoun N, Huyet A-L, Kouiss K (2013) Reconfigurable assembly system configuration design approaches for product change. In: 5th Industrial Engineering and Systems Management, pp 1–8

Andersen AL, Brunoe TD, Nielsen K, Rösiö C (2017) Towards a generic design method for reconfigurable manufacturing systems: analysis and synthesis of current design methods and evaluation of supportive tools. J Manuf Syst 42:179–195

Rabbani M, Samavati M, Ziaee MS, Rafiei H (2014) Reconfigurable dynamic cellular manufacturing system: a new bi-objective mathematical model. RAIRO-Rech Opér 48:75–102

Lee S, Tilbury DM (2007) Deadlock-free resource allocation control for a reconfigurable manufacturing system with serial and parallel configuration. IEEE Trans Syst Man Cybern Part C Appl Rev 37:1373–1381

Padayachee J, Bright G (2014) Synthesis of evolving cells for reconfigurable manufacturing systems. IOP Conf Ser Mater Sci Eng 65:12009–12017

Niroomand I, Kuzgunkaya O, Bulgak AA (2014) The effect of system configuration and ramp-up time on manufacturing system acquisition under uncertain demand. Comput Ind Eng 73:61–74

Koren Y, Wang W, Gu X (2016) Value creation through design for scalability of reconfigurable manufacturing systems. Int J Prod Res 55:1227–1242

Bruccoleri M, Renna P, Perrone G (2005) Reconfiguration: a key to handle exceptions and performance deteriorations in manufacturing operations. Int J Prod Res 43:4125–4145

Aljuneidi T, Bulgak AA (2016) A mathematical model for designing reconfigurable cellular hybrid manufacturing-remanufacturing systems. Int J Adv Manuf Technol 87:1585–1596

Galan R, Racero J, Eguia I, Canca D (2007) A methodology for facilitating reconfiguration in manufacturing: the move towards reconfigurable manufacturing systems. Int J Adv Manuf Technol 33:345–353

Singh RK, Khilwani N, Tiwari MK (2007) Justification for the selection of a reconfigurable manufacturing system: a fuzzy analytical hierarchy based approach. Int J Prod Res 45:3165–3190

Li A, Lv C, Xu L (2007) Analysis and research of system configuration and economic evaluation of reconfigurable manufacturing system. 2007 IEEE Int Conf Robot Biomimetics, ROBIO, pp 1727–1732

Spicer P, Carlo HJ (2007) Integrating reconfiguration cost into the design of multi-period scalable reconfigurable manufacturing systems. J Manuf Sci Eng 129:202

Dou JP, Dai X, Meng Z (2009) Precedence graph-oriented approach to optimise single-product flow-line configurations of reconfigurable manufacturing system. Int J Comput Integr Manuf 22:923–940

Bensmaine A, Dahane M, Benyoucef L (2013) A non dominated sorting genetic algorithm based approach for optimal machines selection in reconfigurable manufacturing environment. Comput Ind Eng 66:519–524

Benderbal HH, Dahane M, Benyoucef L (2015) A new robustness index for machines selection in reconfigurable manufacturing system. Proc 2015 Int Conf Ind Eng Syst Manag IEEE IESM, pp 1019–1026

Goyal KK, Jain PK, Jain M (2013) A novel methodology to measure the responsiveness of RMTs in reconfigurable manufacturing system. J Manuf Syst 32:724–730

Molina A, Rodriguez CA, Ahuett H et al (2005) Next-generation manufacturing systems: key research issues in developing and integrating reconfigurable and intelligent machines. Int J Comput Integr Manuf 18:525–536

Goyal KK, Jain PK, Jain M (2012) Optimal configuration selection for reconfigurable manufacturing system using NSGA II and TOPSIS. Int J Prod Res 50:4175–4191

Eguia I, Molina JC, Lozano S, Racero J (2017) Cell design and multi-period machine loading in cellular reconfigurable manufacturing systems with alternative routing. Int J Prod Res 55:2775–2790

Xiaobo Z, Jiancai W, Zhenbi L (2000) A stochastic model of a reconfigurable manufacturing system part 2: optimal configurations. Int J Prod Res 38:747–758

Cedeno-Campos VM, Trodden PA, Dodd TJ, Heley J (2013) Highly flexible self-reconfigurable systems for rapid layout formation to offer manufacturing services. In: IEEE International Conference on Systems, Man, and Cybernetics, pp 4819–4824

Zheng L, Zhu L, Wang B, Bai L (2013) A simulation analysis of facility layout problems in reconfigurable manufacturing systems. In: International Conference on Computer Sciences and Applications. pp 423–427

Kuo C-H (2001) Resource allocation and performance evaluation of the reconfigurable manufacturing systems. In: International Conference on Systems, Man and Cybernetics, pp 2451–2456

Azevedo MM, Crispim JA, Sousa JP (2013) Flexible and reconfigurable layouts in complex manufacturing systems. IFIP AICT 397:484–493

Azevedo MM, Crispim JA, Sousa JP (2016) Layout design and reconfiguration in a collaborative manufacturing network. In: IFIP AICT. Springer, Cham, pp 545–556

Azevedo MM, Crispim JA, Sousa JP (2017) A dynamic multi-objective approach for the reconfigurable multi-facility layout problem. J Manuf Syst 42:140–152

Purnomo MRA, Wiwoho YS (2016) Multi-objective mixed integer programming approach for facility layout design by considering closeness ratings, material handling, and re-layout cost. IOP Conf Ser Mater Sci Eng 105:012045

Guan X, Dai X, Qiu B, Li J (2012) A revised electromagnetism-like mechanism for layout design of reconfigurable manufacturing system. Comput Ind Eng 63:98–108

Bejlegaard M, Brunoe TD, Nielsen K, Bossen J (2015) Machine-part formation enabling reconfigurable manufacturing systems configuration design: line balancing problem for low volume and high variety. In: Managing Complexity : Proceedings of the 8th World Conference on Mass Customization, Personalization, and Co-Creation (MCPC 2015), pp 139–146

Ren C, Barlotti C, Cohen Y et al (2015) Re-layout of an assembly area: a case study at Bosch Rexroth oil control. Assem Autom 35:94–103

Vitayasak S, Pongcharoen P (2015) Re-layout and robust machine layout design under stochastic demand. Appl Mech Mater 789–790:1252–1257

Lacksonen TA, Chao-Yen H (1998) Project scheduling algorithms for re-layout projects. IIE Trans 30:91–99

Ferrari E, Pareschi A, Persona A, Regattieri A (2003) Plant layout computerised design: logistic and relayout program (LRP). Int J Adv Manuf Technol 21:917–922

Keshavarzmanesh S, Wang L, Feng H-Y (2010) A hybrid approach for dynamic routing planning in an automated assembly shop. Robot Comput Integr Manuf 26:768–777

Maniraj M, Pakkirisamy V, Jeyapaul R (2017) An ant colony optimization-based approach for a single-product flow-line reconfigurable manufacturing systems. Proc Inst Mech Eng B J Eng Manuf 231:1229–1236

Dou J, Dai X, Ma X, Meng Z (2008) A GA-based approach to optimize single-product flow-line configurations of RMS. In: Proceedings of 2008 IEEE International Conference on Mechatronics and Automation, pp 654–659

Kant R, Pandey V, Pattanaik LN (2017) An NSGA II-based approach for optimization of reconfigurable cellular manufacturing system. In: Advances in intelligent systems and computing. Springer, Singapore, pp 57–66

Qiu RG, Mcdonnell P, Joshi S, Russell DW (2005) A heuristic game theoretic approach to resource sharing in reconfigurable manufacturing. Int J Adv Manuf Technol 25:78–87

Fan S, Li J, Catherine A, Pan M (2011) GASD based relayout method in mass customization manufacturing quality assurance. Adv Mater Res 225–226:368–371

Wang G, Yan Y, Zhang X, et al (2008) A simulation optimization approach for facility layout problem. In: International Conference on Industrial Engineering and Engineering Management, pp 734–738

Jiang S, Ong SK, Nee AYC (2014) An AR-based hybrid approach for facility layout planning and evaluation for existing shop floors. Int J Adv Manuf Technol 72:457–473

Yamada Y, Lei J (2006) Reconfiguration process design of a reconfigurable manufacturing system. IMACS Multiconference Computational Eng Syst Appl 1012–1019

Yamada Y (2006) Dynamic reconfiguration of reconfigurable manufacturing systems using particle swarm optimization. In: International Conference on Robotics and Automation, pp 1444–1449

Kia R, Baboli A, Javadian N et al (2012) Solving a group layout design model of a dynamic cellular manufacturing system with alternative process routings, lot splitting and flexible reconfiguration by simulated annealing. Comput Oper Res 39:2642–2658

Kia R, Javadian N, Paydar MM, Saidi-Mehrabad M (2013) A simulated annealing for intra-cell layout design of dynamic cellular manufacturing systems with route selection, purchasing machines and cell reconfiguration. Asia Pacific J Oper Res 30:1350004

Shafigh F, Defersha FM, Moussa SE (2017) A linear programming embedded simulated annealing in the design of distributed layout with production planning and systems reconfiguration. Int J Adv Manuf Technol 88:1119–1140

Kulturel-Konak S, Smith AE, Norman BA (2007) Bi-objective facility expansion and relayout considering monuments. IIE Trans 39:747–761

Giordani S, Lujak M, Martinelli F (2009) A decentralized scheduling policy for a dynamically reconfigurable production system. In: Lecture notes in computer science (including subseries lecture notes in artificial intelligence and lecture notes in bioinformatics). Springer, Berlin Heidelberg, pp 102–113

Leitao P, Barbosa J, Trentesaux D (2012) Bio-inspired multi-agent systems for reconfigurable manufacturing systems. Eng Appl Artif Intell 25:934–944

Hsieh FS (2018) Design of scalable agent-based reconfigurable manufacturing systems with Petri nets. Int J Comput Integr Manuf 31:748–759

AlGeddawy T, ElMaraghy HA (2010) Design of single assembly line for the delayed differentiation of product variants. Flex Serv Manuf J 22:163–182

AlGeddawy T, ElMaraghy HA (2010) Assembly systems layout design model for delayed products differentiation. Int J Prod Res 48:5281–5305

Wu ZJ, Ning RX (2006) Design and application of virtual reconfigurable manufacturing system. In: Proceedings of the 13th International Conference on Industrial Engineering and Engineering Management, pp 763–767

Ming D, Fei L, Forest H et al (2007) Multi-objective layout optimization in dynamic environments: a heuristic approach. Int Conf Manag 05:159–164

Lin HW, Murata T (2010) Decision support for the dynamic reconfiguration of machine layout and part routing in cellular manufacturing. In: Proceedings of the International MultiConference of Engineers and Computer Scientists 2010, IMECS 2010

Lv C, Li AP, Xu LY (2010) Research and optimization of reconfigurable manufacturing system configuration based on system reliability. Kybernetes 39:1058–1065

Abdi MR, Labib AW (2004) Feasibility study of the tactical design justification for reconfigurable manufacturing systems using the fuzzy analytical hierarchical process. Int J Prod Res 42:3055–3076

Al-Zaher A, Elmaraghy W, Pasek ZJ (2013) RMS design methodology for automotive framing systems BIW. J Manuf Syst 32:436–448

Izquierdo LE, Hu SJ, Du H et al (2009) Robust fixture layout design for a product family assembled in a multistage reconfigurable line. J Manuf Sci Eng 131:041008

Jefferson TG, Benardos P, Ratchev S (2016) Reconfigurable assembly system design methodology: a wing assembly case study. Int J Mater Manuf 9:31–48

Kamrani AK (2003) A template-based engineering methodology for integrated product design and reconfigurable manufacturing layout. Int J Ind Eng Theory Appl Pract 10:147–156

Kochhar JS, Heragu SS (1999) Facility layout design in a changing environment. Int J Prod Res 37:2429–2446

Li J, Dai X, Meng Z et al (2009) Rapid design and reconfiguration of Petri net models for reconfigurable manufacturing cells with improved net rewriting systems and activity diagrams. Comput Ind Eng 57:1431–1451

Moghaddam SK, Houshmand M, Valilai OF (2018) Configuration design in scalable reconfigurable manufacturing systems (RMS); a case of single-product flow line (SPFL). Int J Prod Res 56:3932–3954

Unglert J, Becker JJ, Hoekstra S (2016) Computational design synthesis of reconfigurable cellular manufacturing systems: a design engineering model. Procedia CIRP 57:374–379

Unglert J, Hoekstra S, Becker JJ, van Houten F (2016) Towards decision-support for reconfigurable manufacturing systems based on computational design synthesis. Procedia CIRP 41:153–158

Unglert J, Hoekstra S, Becker JJ (2016) Supporting the design of reconfigurable cellular manufacturing systems by computational design synthesis. In: DS 84: Proceedings of the DESIGN 2016 14th International Design Conference, pp 1417–1426

Zhang S, Li Y, Bilberg A, Hadar R (2014) Design and evaluation of a reconfigurable manufacturing system. In: Lecture Notes in Production Engineering: Twenty Years of Mass Customization – Towards New Frontiers, pp 115–127

Benama Y, Alix T, Perry N (2014) Reconfigurable manufacturing system design: the case of mobile manufacturing system. In: Advances in Production Management Systems (Ajaccio; 2014), pp 1–8

Dou J, Dai X, Meng Z (2007) Optimization for flow-line configurations of RMS based on graph theory. Proc 2007 IEEE Int Conf Mechatronics Autom ICMA 2007 1261–1266

Farid AM (2013) An axiomatic design approach to production path enumeration in reconfigurable manufacturing systems. 2013 IEEE Int Conf Syst Man, Cybern, pp 3862–3869

Guerra-Zubiaga D, Rosas R, Camacho R, Molina A (2005) Information models to support reconfigurable manufacturing system design. In: Bouras A, Gurumoorthy B, Sudarsan R (eds) Product lifecycle management: emerging solutions and challenges for global networked enterprises. Inderscience Enterprises Limited, Genève, pp 55–63

Huang L, Gao Y, Qian F et al (2010) Configuration selection for reconfigurable manufacturing systems by means of characteristic state space. Chinese J Mech Eng 23:1–10

Kahloul L, Bourekkache S, Djouani K (2016) Designing reconfigurable manufacturing systems using reconfigurable object Petri nets. Int J Comput Integr Manuf 29:889–906

Lamotte FF, Berruet P, Philippe JL (2006) Evaluation of reconfigurable manufacturing systems configurations using tolerance criteria. IECON Proc Industrial Electron Conf pp 3715–3720

Chao L, Aiping L, Liyun X (2007) The research of performance evaluation system on manufacturing system with reconfigurable configuration. Proc 2007 IEEE Int Conf Mechatronics Autom ICMA 2007 pp 1005–1010

Orozco OJL, Lastra JLM (2007) Analysis and design of a distributed model of coordination control for reconfigurable manufacturing systems. In: Proceedings of the 13th IASTED International Conference on Robotics and Applications, pp 537–542

Tang Y, Qiu RG (2004) Integrated design approach for virtual production line-based reconfigurable manufacturing systems. Int J Prod Res 42:3803–3822

Wang Q, Lassalle S, Mileham AR, Owen GW (2009) Analysis of a linear walking worker line using a combination of computer simulation and mathematical modeling approaches. J Manuf Syst 28:64–70

Baqai A, Shafiq A (2013) Dimensional analysis of the generated design solutions for reconfigurable manufacturing system. Int Mech Eng Congr Expo IMECE pp 1–7

Schmidt KW (2013) Optimal configuration changes for reconfigurable manufacturing systems. 52nd IEEE Conf Decis Control 16:7621–7626

Yamada Y, Ookoudo K, Komura Y (2003) Layout optimization of manufacturing cells and allocation optimization of transport robots in reconfigurable manufacturing systems using particle swarm optimization. Proc 2003 IEEE/RSJ Int Conf Intell Robot Syst 2:2049–2054

Zheng P, Wang H, Sang Z et al (2018) Smart manufacturing systems for industry 4.0: conceptual framework, scenarios, and future perspectives. Front Mech Eng 13:137–150

Scholz S, Mueller T, Plasch M, Limbeck H, Adamietz R, Iseringhausen T, Kimmig D, Dickerhof M, Woegerer C (2016) A modular flexible scalable and reconfigurable system for manufacturing of microsystems based on additive manufacturing and e-printing. Robot Comput Integr Manuf 40:14–23

Wang L (2011) Combining facility layout redesign and dynamic routing for job-shop assembly operations. In: International Symposium on Assembly and Manufacturing, ISAM 2011, pp 1–6

Singh A, Gupta S, Asjad M, Gupta P (2017) Reconfigurable manufacturing systems: journey and the road ahead. Int J Syst Assur Eng Manag 8:1849–1857

Maganha I, Silva C, Ferreira LMDF (2018) Understanding reconfigurability of manufacturing systems: an empirical analysis. J Manuf Syst 48:120–130

Bortolini M, Galizia FG, Mora C (2018) Reconfigurable manufacturing systems: literature review and research trend. J Manuf Syst 49:93–106

Funding

This research was supported by the Portugal 2020 project DM4Manufacturing POCI-01-0145-FEDER-016418 by UE/FEDER through the program COMPETE2020.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Maganha, I., Silva, C. & Ferreira, L.M.D.F. The layout design in reconfigurable manufacturing systems: a literature review. Int J Adv Manuf Technol 105, 683–700 (2019). https://doi.org/10.1007/s00170-019-04190-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04190-3