Abstract

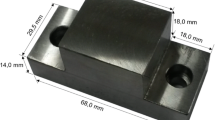

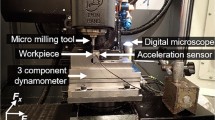

Stainless steel is a well-known difficult-to-machine material with high toughness, low thermal conductivity, and high work hardening characteristics. Burrs generated in micromilling of the stainless steel seriously affect the performances of the fabricated high-accuracy miniaturized geometrical features. Aiming at reasonable control of burrs in micromilling of the 304 austenitic stainless steel, single-factor analyses, multi-factor optimization, and further post processing procedures are introduced in the paper. First, the axial depth of cut ap, feed per tooth fz, spindle speed n, and radial depth of cut ae are investigated by single-factor micromilling experiments. It shows that burrs generated in up milling are smaller than that in down milling. The minimum burr widths of 171.93 μm can be achieved, and the overall trend of micromilling force is in accordance with the burr widths. Then, multi-factor orthogonal experiments have been carried out to optimize micromilling parameters based on the Taguchi method. It shows that the significance sequence of key parameters for burr widths from large to small is ap, n, ae, and fz. The optimized minimum burr width is 83.69 μm with micromilling parameters ap of 45 μm, fz of 1.0 μm/z, n of 48,000 min−1, and ae of 200 μm. To further reduce the burrs, ap of 0 is set for post processing experiments. It shows that the radial depth of cut affects burr sizes greatly. The optimized radial depth of cut is 500 μm, and burr widths have been finally reduced to 14.3 μm. The study provides an effective method to reduce burr sizes in micromilling of very ductile materials.

Similar content being viewed by others

References

Gao Q, Gong Y, Zhou Y (2017) Experimental study of micro-milling mechanism and surface quality of a nickel-based single crystal super alloy. J Mech Sci Technol 31(1):171–180. https://doi.org/10.1007/s12206-016-1218-y

Lekkala R, Bajpai V, Singh RK (2011) Characterization and modeling of burr formation in micro-end milling. Precis Eng 35(4):625–637. https://doi.org/10.1016/j.precisioneng.2011.04.007

Chen MJ, Ni HB, Wang ZJ (2012) Research on the modeling of burr formation process in micro-ball end milling operation on Ti–6Al–4V. Int J Adv Manuf Technol 62(9–12):901–912. https://doi.org/10.1016/j.precisioneng.2011.04.007

Kuram E, Ozcelik B (2016) Micro-milling performance of AISI 304 stainless steel using Taguchi method and fuzzy logic modelling. J Intell Manuf 27(4):817–830. https://doi.org/10.1007/s10845-014-0916-5

Dornfeld D, Min SA (2009) Review of burr formation in machining burrs-analysis, control and removal. In: Proceedings of the CIRP International Conference on Burrs, 2009. https://doi.org/10.1007/978-3-642-00568-8_1

Liu K, Melkote SN (2007) Finite element analysis of the influence of tool edge radius on size effect in orthogonal micro-cutting process. Int J Mech Sci 49:650–660. https://doi.org/10.1016/j.ijmecsci.2006.09.012

Bissacco G, Hansen HN, Chiffre L (2005) Micromilling of hardened tool steel for mould making applications. J Mater Process Technol 167:201–207. https://doi.org/10.1016/j.jmatprotec.2005.05.029

Zhang T, Liu ZQ, Xu CH (2013) Influence of size effect on burr formation in micro cutting. Int J Adv Manuf Technol 170:4801–4808. https://doi.org/10.1007/s00170-013-4801-8

Lee R, Dornfeld DA (2002) An experimental study on burr formation in micro milling aluminum and copper. Trans NAMRI/ SME 30:1–8. https://doi.org/10.1347/s0080015797686

Bajpai V, Kushwaha AK, Singh RK (2013) Burr formation and surface quality in high speed micromilling of titanium alloy (Ti6Al4V). Proceedings of the ASME 2013 International Manufacturing Science and Engineering Conference collocated with the 41st North American Manufacturing Research Conference, 2013 17–24. https://doi.org/10.1115/MSEC2013-1216

Piquard R, D’Acunto A, Laheurte P (2014) Micro-end milling of NiTi biomedical alloys, burr formation and phase transformation. Precis Eng 38(2):356–364. https://doi.org/10.1016/j.precisioneng.2013.11.006

Kienzler A, Deuchert M, Schulze V (2010) Burr minimization and removal by micro milling strategies or micro peening processes. Burrs - Analysis, Control and Removal 2010. 237–243. https://doi.org/10.1007/978-3-642-00568-8_26

Kou ZJ, Wan Y (2015) Burr controlling in micro milling with supporting material method. Procedia Manuf 1:501–511. https://doi.org/10.1016/j.promfg.2015.09.015

Khanghah SP, Boozarpoor M, Lotfi M (2015) Optimization of micro-milling parameters regarding burr size minimization via RSM and simulated annealing algorithm. T Indian I Metals 68(5):897–910. https://doi.org/10.1007/s12666-015-0525-9

Cheng X, Yang XH, Li L (2013) Design of a three-axis desktop micro milling machine tool. Key Eng Mater 589-590:735–739. https://doi.org/10.4028/www.scientific.net/kem.589-590.735

Cheng X, Liu J, Zheng GM, Yang XH, Tian YB (2018) Study of microcutting fundamentals for peripheral and end cutting edges in micro-end-milling. J Micromech Microeng 28:015011. https://doi.org/10.1088/1361-6439/aa9a73

Wang F, Cheng X, Guo Q (2018) Experimental study on micromilling of thin walls. J Micromech Microeng 29(1):015009. https://doi.org/10.1088/1361-6439/aaeecb

Cheng X, Wei XT, Yang XH (2014) Unified criterion for brittle-ductile transition in mechanical microcutting of brittle materials. J Manuf Sci E T ASME 136(5):0510131–0510138. https://doi.org/10.1115/1.4027996

Aurich JC, Dornfeld D, Arrazola PJ (2009) Burrs—analysis, control and removal. CIRP Ann Manuf Technol 58(2):519–542. https://doi.org/10.1016/j.cirp.09.004

Aramcharoen A, Mativenga PT (2009) Size effect and tool geometry in micromilling of tool steel. Precis Eng 33(4):402–407. https://doi.org/10.1016/j.precisioneng.2008.11.002

Vogler MP, Devor RE, Kapoor SG (2004) On the modeling and analysis of machining performance in micro-end milling. Part I: surface generation. J Manuf Sci Eng 126:685–694. https://doi.org/10.1115/1.1813470

Wu X, Li L, He N (2016) Investigation on the burr formation mechanism in micro cutting. Precis Eng 47:191–196. https://doi.org/10.1016/j.precisioneng.2016.08.004

da Silva LC, da Mota PR (2015) Study of burr behavior in face milling of PH 13-8 Mo stainless steel. CIRP J Manuf Sci Technol 8:34–42. https://doi.org/10.1016/j.cirpj.2014.10.003

Funding

The paper is financially supported by the Nature Science Foundation of Shandong Province with the grant number of ZR2015EL023, the Nature Science Foundation of China with the grant number of 51505264, and the SDUT & Zibo City Integration Development Project with the grant number of 2017ZBXC189.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, Q., Cheng, X., Zhao, G. et al. Experimental study of micromilling burrs of 304 stainless steel. Int J Adv Manuf Technol 105, 4651–4662 (2019). https://doi.org/10.1007/s00170-019-03839-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03839-3