Abstract

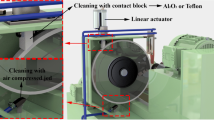

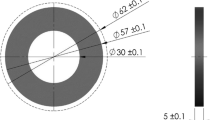

High thermal loads generated during grinding of ceramic materials increase abrasive tool wear and damage workpiece quality. In this regard, the application of cutting fluid has been mandatory, although several researchers have been working to reduce oil consumption in such processes, as it increases the cost of the final product and is harmful to both people and environment. Among the alternatives, minimum quantity lubrication (MQL) has been increasingly investigated, even though clogging of the grinding wheel is prone to occur. In order to improve the cleaning of the abrasive tool during the process and reduce oil consumption, this paper proposes the investigation of the performance of MQL technique applied together with a wheel cleaning system, which consists of a compressed air jet directed to the wheel surface, during grinding of alumina. Different direction angles of the air jet were tested and conventional flood coolant as well as MQL alone were applied for comparison purposes. Flood coolant was the most efficient method regarding cleaning of the grinding wheel, decrease of diametral wheel wear, surface roughness, and average power followed by the use of MQL with an air jet directed to the wheel surface with an angle of 30°. This latter arrangement, however, can become an option when the reduction of oil consumption is a priority, as it provides the best results when compared to the other air jet direction angle configurations.

Similar content being viewed by others

References

Zhang B, Zheng XL, Tokura H, Yoshikawa M (2003) Grinding induced damage in ceramics. J Mater Process Technol 132:353–364

Yin L, Huang H, Ramesh K, Huang T (2005) High speed versus conventional grinding in high removal rate machining of alumina and alumina-titania. Int J Mach Tools Manuf 45:897–907

Chen J, Huang H, Xu X (2009) An experimental study on the grinding of alumina with a monolayer brazed diamond wheel. Int J Adv Manuf Technol 41:16–23

Liao TW, Sathyanarayanan G (1994) On the study of creep feed grinding of alumina. Int J Mach Tools Manuf 34:257–276

Tuan WH, Kuo JC (1998) Effect of grinding parameters on the reliability of alumina. Mater Chem Phys 52:41–45

Liao TW, Li K, McSpadden SB Jr, O’Rourke LJ (1997) Wear of diamond wheels in creep-feed grinding of ceramic materials – I. Mechanisms. Wear 211:94–103

Liao TW, Li K, McSpadden SB Jr (2000) Wear mechanisms of diamond abrasives during transition and steady stages in creep-feed grinding of structural ceramics. Wear 242:28–37

Li K, Liao TW, O’Rourke LJ, McSpadden SB Jr (1997) Wear of diamond wheels in creep-feed grinding of ceramic materials – II. Effects on process responses and strength. Wear 211:104–112

Zhang B, Fu Y (2013) Grinding of brittle materials with brazed diamond grinding wheel. Int J Adv Manuf Technol 67:2845–2852

Zhang Q, Zhao Q, To S, Guo B, Zhai W (2017) Diamond wheel wear mechanism and its impact on the surface generation in parallel diamond grinding of RB-SiC/Si. Diam Relat Mater 74:16–23

Hadad MJ, Tawakoli T, Sadeghi MH, Sadeghi B (2012) Temperature and energy partition in minimum quantity lubrication – MQL grinding process. Int J Mach Tools Manuf 54-55:10–17

Tawakoli T, Hadad MJ, Sadeghi MH, Daneshi A, Stöckert S, Rasifard A (2009) An experimental investigation of the effects of workpiece and grinding parameters on minimum quantity lubrication – MQL grinding. Int J Mach Tools Manuf 49:924–932

Simões RP, Bianchi EC, Oikawa MH, Aguiar PR, Droppa Júnior R, Canarim RC (2014) Evaluation of different methods of cooling-lubrication in cylindrical grinding of advanced ceramic dip. Mater Res 17:1201–1212

Tawakoli T, Hadad M, Sadeghi MH, Daneshi A, Sadeghi B (2011) Minimum quantity lubrication in grinding: effects of abrasive and coolant-lubricant types. J Clean Prod 19:2088–2099

Emami M, Sadeghi MH, Sarhan AAD, Hasani F (2014) Investigating the minimum quantity lubrication in grinding of Al2O3 engineering ceramic. J Clean Prod 66:632–643

Emami M, Sadeghi MH, Sarhan AAD (2013) Investigating the effects of liquid atomization and delivery parameters of minimum quantity lubrication on the grinding process of Al2O3 engineering ceramics. J Manuf Process 15:374–388

Jia D, Li C, Zhang Y, Zhang D, Zhang X (2016) Experimental research on the influence of the jet parameters of minim quantity lubrication on the lubricating property of Ni-based alloy grinding. Int J Adv Manuf Technol 82:617–630

Nadolny K, Wojtewicz M, Sienicki W, Herman D (2015) An analysis of centrifugal MQL supply system potential in the internal cylindrical grinding process. Arch Civil Mech Eng 15:639–649

Chen X, Feng Z (2003) Effectiveness of laser cleaning for grinding wheel loading. Key Eng Mater 238-239:289–294

Jackson MJ, Khangar A, Chen X, Robinson GM, Venkatesh VC, Dahotre NB (2007) Laser cleaning and dressing of vitrified grinding wheels. J Mater Process Technol 185:17–23

Oliveira DJ, Guermandi LG, Bianchi EC, Diniz AE, Aguiar PR, Canarim RC (2012) Improving minimum quantity lubrication in CBN grinding using compressed air wheel cleaning. J Mater Process Technol 212:2559–2568

Bianchi EC, Rodriguez RL, Hildebrandt RA, Lopes JC, Mello HJ, Silva RB, Aguiar PR (2018) Plunge cylindrical grinding with the minimum quantity lubrication coolant technique assisted with wheel cleaning system. Int J Adv Manuf Technol 95:2907–2916

Lopes JC, Ventura CEH, Rodrigues RL, Talon AG, Volpato RS, Sato BK, Mello HJ, Aguiar PR, Bianchi EC (2018) Application of minimum quantity lubrication with addition of water in the grinding of alumina. Int J Adv Manuf Technol 97:1951–1959

Malkin S, Guo C (2008) Grinding technology: theory and applications of machining with abrasives. Industrial Press, New York

Acknowledgements

The authors would like to thank the Department of Mechanical Engineering of the Faculty of Engineering of UNESP Bauru. Additional thanks go to Dinser Ferramentas Diamantadas for the donation of the diamond grinding wheel, Máquinas Agrícolas Jacto S/A for the donation of the workpieces and ITW Chemical Products Ltda. for the donation of the cutting fluids.

Funding

This work was supported by the São Paulo Research Foundation – FAPESP (grant numbers 2015/10460-4 and 2017/03789-5).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lopes, J.C., Ventura, C.E.H., de M. Fernandes, L. et al. Application of a wheel cleaning system during grinding of alumina with minimum quantity lubrication. Int J Adv Manuf Technol 102, 333–341 (2019). https://doi.org/10.1007/s00170-018-3174-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-3174-4