Abstract

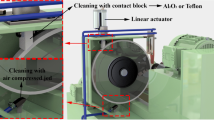

With the evolution of the sustainable industry, the grinding process seeks to follow the requirements to continue to be highly employed when precision and low-dimensional tolerances are required in the workpieces. In this way, the cutting fluids used in the process, which are essential for a good surface finish, are the main impasse to ensure that the process becomes eco-friendly. Therefore, a widespread lubri-refrigeration method in the industry is the flood technique, which uses a lot of fluid to reduce the high temperatures generated during grinding. However, the use of the flood method generates many undesirable residues that affect the machine operator, the environment, and production costs. Thus, several alternatives have emerged to address these problems, for example, the minimum quantity of lubricant (MQL), the wheel cleaning jet system (WCJ), and the application of cooled air (CA). Therefore, this work sought to analyze the combination of these systems (MQL+CA, MQL+WCJ, and MQL) in the grinding of AISI 4340 steel using an aluminum oxide wheel (Al2O3) and to verify their performance compared with the flood method, in addition to employing a new method known as cooled wheel cleaning jet (CWCJ). Therefore, the tests of surface roughness (Ra and Rz), roundness error, diametrical wheel wear, G ratio, grinding power, tangential cutting force, and microhardness were performed, and optical, confocal, and scanning electron microscopy also were analyzed. Thus, the results that came closest to the flood method in all tests were achieved by systems that applied grinding wheel cleaning (MQL + WCJ and MQL + CWCJ), being that in the diametrical wheel wear and G ratio the MQL + CWCJ even managed to surpass it. Besides, the MQL+CA union showed better values when compared with MQL without any assistance. Thus, applying MQL with helper systems, mainly CWCJ, contributed to a more economical, efficient, and sustainable grinding process.

Similar content being viewed by others

References

Lopes JC, Garcia MV, Valentim M, Javaroni RL, Ribeiro FSF, de Angelo Sanchez LE, de Mello HJ, Aguiar PR, Bianchi EC (2019) Grinding performance using variants of the MQL technique: MQL with cooled air and MQL simultaneous to the wheel cleaning jet. Int J Adv Manuf Technol 105:4429–4442. https://doi.org/10.1007/s00170-019-04574-5

Rodriguez RL, Lopes JC, Garcia MV, Tarrento GE, Rodrigues AR, de Ângelo Sanchez LE, de Mello HJ, de Aguiar PR, Bianchi EC (2020) Grinding process applied to workpieces with different geometries interrupted using CBN wheel. Int J Adv Manuf Technol 107:1265–1275. https://doi.org/10.1007/s00170-020-05122-2

Lopes JC, de Martini Fernandes L, Garcia MV et al (2020) Performance of austempered ductile iron ( ADI ) grinding using diluted oil in MQL combined with wheel cleaning jet and different CBN grains friability. Int J Adv Manuf Technol 107:1805–1818. https://doi.org/10.1007/s00170-020-05142-y

Alexandre FA, Lopes JC, de Martini FL et al (2020) Depth of dressing optimization in CBN wheels of different friabilities using acoustic emission (AE) technique. Int J Adv Manuf Technol 106:5225–5240. https://doi.org/10.1007/s00170-020-04994-8

de Moraes DL, Garcia MV, Lopes JC, Ribeiro FSF, de Angelo Sanchez LE, Foschini CR, de Mello HJ, Aguiar PR, Bianchi EC (2019) Performance of SAE 52100 steel grinding using MQL technique with pure and diluted oil. Int J Adv Manuf Technol 105:4211–4223. https://doi.org/10.1007/s00170-019-04582-5

Talon AG, Lopes JC, Tavares AB, Sato BK, Rodrigues AR, Genovez MC, Dinis Pinto TA, de Mello HJ, Aguiar PR, Bianchi EC (2019) Effect of hardened steel grinding using aluminum oxide wheel under application of cutting fluid with corrosion inhibitors. Int J Adv Manuf Technol 104:1437–1448. https://doi.org/10.1007/s00170-019-04005-5

Garcia MV, Lopes JC, Diniz AE, Rodrigues AR, Volpato RS, Sanchez LEA, de Mello HJ, Aguiar PR, Bianchi EC (2020) Grinding performance of bearing steel using MQL under different dilutions and wheel cleaning for green manufacture. J Clean Prod 257:120376. https://doi.org/10.1016/j.jclepro.2020.120376

Shokrani A, Dhokia V, Newman ST (2012) Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int J Mach Tools Manuf 57:83–101. https://doi.org/10.1016/j.ijmachtools.2012.02.002

Talon AG, Lopes JC, Sato BK, Tavares AB, Ribeiro FSF, Genovez MC, Pinto TAD, de Mello HJ, Aguiar PR, Bianchi EC (2020) Grinding performance of hardened steel: a study about the application of different cutting fluids with corrosion inhibitor. Int J Adv Manuf Technol 108:2741–2754. https://doi.org/10.1007/s00170-020-05598-y

Ribeiro FSF, Lopes JC, Garcia MV, de Angelo Sanchez LE, de Mello HJ, de Aguiar PR, Bianchi EC (2020) Grinding assessment of workpieces with different interrupted geometries using aluminum oxide wheel with vitrified bond. Int J Adv Manuf Technol 108:931–941. https://doi.org/10.1007/s00170-020-05500-w

Javaroni RL, Lopes JC, Garcia MV, Ribeiro FSF, de Angelo Sanchez LE, de Mello HJ, Aguiar PR, Bianchi EC (2020) Grinding hardened steel using MQL associated with cleaning system and cBN wheel. Int J Adv Manuf Technol 107:2065–2080. https://doi.org/10.1007/s00170-020-05169-1

de Martini FL, Lopes JC, Volpato RS et al (2018) Comparative analysis of two CBN grinding wheels performance in nodular cast iron plunge grinding. Int J Adv Manuf Technol 98:237–249. https://doi.org/10.1007/s00170-018-2133-4

Rodriguez RL, Lopes JC, Mancini SD, de Ângelo Sanchez LE, de Almeida Varasquim FMF, Volpato RS, de Mello HJ, de Aguiar PR, Bianchi EC (2019) Contribution for minimization the usage of cutting fluids in CFRP grinding. Int J Adv Manuf Technol 103:487–497. https://doi.org/10.1007/s00170-019-03529-0

Li G, Yi S, Li N, Pan W, Wen C, Ding S (2019) Quantitative analysis of cooling and lubricating effects of graphene oxide nanofluids in machining titanium alloy Ti6Al4V. J Mater Process Technol 271:584–598. https://doi.org/10.1016/j.jmatprotec.2019.04.035

Revuru RS, Posinasetti NR, Vsn VR, Amrita M (2017) Application of cutting fluids in machining of titanium alloys—a review. Int J Adv Manuf Technol 91:2477–2498. https://doi.org/10.1007/s00170-016-9883-7

Silva LR, Corrêa ECS, Brandão JR, de Ávila RF (2020) Environmentally friendly manufacturing: behavior analysis of minimum quantity of lubricant - MQL in grinding process. J Clean Prod 256:103287. https://doi.org/10.1016/j.jclepro.2013.01.033

Lavisse B, Lefebvre A, Torrance AAA et al (2018) The effects of the flow rate and speed of lubricoolant jets on heat transfer in the contact zone when grinding a nitrided steel. J Manuf Process 35:233–243. https://doi.org/10.1016/j.jmapro.2018.07.029

Javaroni RL, Lopes JC, Sato BK, Sanchez LEA, Mello HJ, Aguiar PR, Bianchi EC (2019) Minimum quantity of lubrication (MQL) as an eco-friendly alternative to the cutting fluids in advanced ceramics grinding. Int J Adv Manuf Technol 103:2809–2819. https://doi.org/10.1007/s00170-019-03697-z

Mandal B, Singh R, Das S, Banerjee S (2011) Improving grinding performance by controlling air flow around a grinding wheel. Int J Mach Tools Manuf 51:670–676. https://doi.org/10.1016/j.ijmachtools.2011.06.003

Li B, Li C, Zhang Y, Wang Y, Jia D, Yang M, Zhang N, Wu Q, Han Z, Sun K (2017) Heat transfer performance of MQL grinding with different nanofluids for Ni-based alloys using vegetable oil. J Clean Prod 154:1–11. https://doi.org/10.1016/j.jclepro.2017.03.213

Ribeiro FSF, Lopes JC, Garcia MV, de Angelo Sanchez LE, de Mello HJ, de Aguiar PR, Bianchi EC (2020) Grinding performance by applying MQL technique: an approach of the wheel cleaning jet compared with wheel cleaning Teflon and Alumina block. Int J Adv Manuf Technol 107:4415–4426. https://doi.org/10.1007/s00170-020-05334-6

Sato BK, Lopes JC, Diniz AE, Rodrigues AR, de Mello HJ, Sanchez LEA, Aguiar PR, Bianchi EC (2020) Toward sustainable grinding using minimum quantity lubrication technique with diluted oil and simultaneous wheel cleaning. Tribol Int 147:106276. https://doi.org/10.1016/j.triboint.2020.106276

Mao C, Zhang J, Huang Y, Zou H, Huang X, Zhou Z (2013) Investigation on the effect of nanofluid parameters on MQL grinding. Mater Manuf Process 28:436–442. https://doi.org/10.1080/10426914.2013.763970

Said Z, Gupta M, Hegab H, Arora N, Khan AM, Jamil M, Bellos E (2019) A comprehensive review on minimum quantity lubrication (MQL) in machining processes using nano-cutting fluids. Int J Adv Manuf Technol 105:2057–2086. https://doi.org/10.1007/s00170-019-04382-x

de Mello Belentani R, Funes Júnior H, Canarim RC et al (2013) Utilization of minimum quantity lubrication (MQL) with water in CBN grinding of steel. Mater Res 17:88–96. https://doi.org/10.1590/s1516-14392013005000165

Moretti GB, de Moraes DL, Garcia MV, Lopes JC, Ribeiro FSF, Foschini CR, de Mello HJ, Sanchez LEDA, Aguiar PR, Bianchi EC (2020) Grinding behavior of austempered ductile iron: a study about the effect of pure and diluted MQL technique applying different friability wheels. Int J Adv Manuf Technol 108:3661–3673. https://doi.org/10.1007/s00170-020-05577-3

Stachurski W, Nadolny K (2018) Influence of the condition of the surface layer of a hob cutter sharpened using the MQL-CCA hybrid method of coolant provision on its operational wear. Int J Adv Manuf Technol 98:2185–2200. https://doi.org/10.1007/s00170-018-2379-x

Saberi A, Rahimi AR, Parsa H, Ashrafijou M, Rabiei F (2016) Improvement of surface grinding process performance of CK45 soft steel by minimum quantity lubrication (MQL) technique using compressed cold air jet from vortex tube. J Clean Prod 131:728–738. https://doi.org/10.1016/j.jclepro.2016.04.104

Lopes JC, Fragoso KM, Garcia MV, Ribeiro FSF, Francelin AP, de Angelo Sanchez LE, Rodrigues AR, de Mello HJ, Aguiar PR, Bianchi EC (2019) Behavior of hardened steel grinding using MQL under cold air and MQL CBN wheel cleaning. Int J Adv Manuf Technol 105:4373–4387. https://doi.org/10.1007/s00170-019-04571-8

Bianchi EC, Rodriguez RL, Hildebrandt RA, Lopes JC, de Mello HJ, da Silva RB, de Aguiar PR (2018) Plunge cylindrical grinding with the minimum quantity lubrication coolant technique assisted with wheel cleaning system. Int J Adv Manuf Technol 95:2907–2916. https://doi.org/10.1007/s00170-017-1396-5

Brinksmeier E, Meyer D, Huesmann-Cordes AG, Herrmann C (2015) Metalworking fluids - Mechanisms and performance. CIRP Ann Manuf Technol 64:605–628. https://doi.org/10.1016/j.cirp.2015.05.003

Bianchi EC, Rodriguez RL, Hildebrandt RA, Lopes JC, de Mello HJ, de Aguiar PR, da Silva RB, Jackson MJ (2019) Application of the auxiliary wheel cleaning jet in the plunge cylindrical grinding with minimum quantity lubrication technique under various flow rates. Proc Inst Mech Eng B J Eng Manuf 233:1144–1156. https://doi.org/10.1177/0954405418774599

Lopes JC, Garcia MV, Volpato RS, de Mello HJ, Ribeiro FSF, de Angelo Sanchez LE, de Oliveira Rocha K, Neto LD, Aguiar PR, Bianchi EC (2020) Application of MQL technique using TiO2 nanoparticles compared to MQL simultaneous to the grinding wheel cleaning jet. Int J Adv Manuf Technol 106:2205–2218. https://doi.org/10.1007/s00170-019-04760-5

Lopes JC, Ventura CEH, de M. Fernandes L et al (2019) Application of a wheel cleaning system during grinding of alumina with minimum quantity lubrication. Int J Adv Manuf Technol 102:333–341. https://doi.org/10.1007/s00170-018-3174-4

Tawakoli T, Hadad MJ, Sadeghi MH (2010) Influence of oil mist parameters on minimum quantity lubrication - MQL grinding process. Int J Mach Tools Manuf 50:521–531. https://doi.org/10.1016/j.ijmachtools.2010.03.005

Li X, Li Y (2016) Chain-to-chain competition on product sustainability. J Clean Prod 112:2058–2065. https://doi.org/10.1016/j.jclepro.2014.09.027

King RI, Hahn RS, Devereux OF (2009) Handbook of modern grinding technology. J Eng Mater Technol 109:353. https://doi.org/10.1115/1.3225989

Malkin S, Guo C (2008) Grinding technology: theory and applications of machining with abrasives, 2nd edn. Industrial Press Inc, New York

Damasceno RF, de Souza Ruzzi R, França TV et al (2017) Performance evaluation of various cooling-lubrication techniques in grinding of hardened AISI 4340 steel with vitrified bonded CBN wheel. Int J Adv Manuf Technol 92:3795–3806. https://doi.org/10.1007/s00170-017-0434-7

Bianchi EC, Sato BK, Sales AR, Lopes JC, de Mello HJ, de Angelo Sanchez LE, Diniz AE, Aguiar PR (2018) Evaluating the effect of the compressed air wheel cleaning in grinding the AISI 4340 steel with CBN and MQL with water. Int J Adv Manuf Technol 95:2855–2864. https://doi.org/10.1007/s00170-017-1433-4

Sato BK, Rodriguez RL, Talon AG, Lopes JC, Mello HJ, Aguiar PR, Bianchi EC (2019) Grinding performance of AISI D6 steel using CBN wheel vitrified and resinoid bonded. Int J Adv Manuf Technol 105:2167–2182. https://doi.org/10.1007/s00170-019-04407-5

Zhang J, Li C, Zhang Y, Yang M, Jia D, Liu G, Hou Y, Li R, Zhang N, Wu Q, Cao H (2018) Experimental assessment of an environmentally friendly grinding process using nanofluid minimum quantity lubrication with cryogenic air. J Clean Prod 193:236–248. https://doi.org/10.1016/j.jclepro.2018.05.009

da Silva AE, Lopes JC, Daniel DM, de Moraes DL, Garcia MV, Ribeiro FSF, de Mello HJ, Sanchez LEDA, Aguiar PR, Bianchi EC (2020) Behavior of austempered ductile iron (ADI) grinding using different MQL dilutions and CBN wheels with low and high friability. Int J Adv Manuf Technol 107:4373–4387. https://doi.org/10.1007/s00170-020-05347-1

Acknowledgments

The authors also thank companies Nikkon Ferramentas de Corte Ltda—Saint Gobain Group for providing the grinding wheel, ITW Chemical Products for the donation the cutting fluids, and the authors thank everyone by support to the research and opportunity for scientific and technological development.

Funding

The authors thank São Paulo Research Foundation (FAPESP) processes 2019/24933-2 and 2020/06038-3, CAPES (Coordination for the Improvement of Higher Level Education Personnel), and CNPq (National Council for Scientific and Technological Development) for their financial support of this research.

Author information

Authors and Affiliations

Contributions

Douglas Lyra de Moraes: writing—original draft; writing—review and editing; visualization; conceptualization; formal analysis; investigation; validation.

José Claudio Lopes: writing—original draft; writing—review and editing; visualization; conceptualization; formal analysis; investigation; validation.

Bruno Vicente Andrioli: writing—original draft; writing—review and editing; visualization; conceptualization; formal analysis; investigation; validation.

Guilherme Bressan Moretti: writing—original draft; writing—review and editing; visualization; conceptualization; formal analysis; investigation; validation.

Andrigo Elisiario da Silva: writing—original draft; writing—review and editing; visualization; conceptualization; formal analysis; investigation; validation.

Jean Machado Maciel da Silva: writing—original draft; investigation; data curation; formal analysis.

Fernando Sabino Fonteque Ribeiro: conceptualization; methodology; validation; writing—original draft.

Hamilton José de Mello: conceptualization; methodology; formal analysis; investigation; validation.

Paulo Roberto Aguiar: software; supervision.

Eduardo Carlos Bianchi: funding acquisition; conceptualization; resources; supervision; project administration.

Corresponding author

Ethics declarations

Ethical approval

The authors declare that this manuscript was not submitted to more than one journal for simultaneous consideration. Also, the submitted work is original and not have been published elsewhere in any form or language.

Consent to participate and publish

The authors declare that they participated in this manuscript willingly and the authors declare to consent to the publication of this manuscript.

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Moraes, D.L., Lopes, J.C., Andrioli, B.V. et al. Advances in precision manufacturing towards eco-friendly grinding process by applying MQL with cold air compared with cooled wheel cleaning jet. Int J Adv Manuf Technol 113, 3329–3342 (2021). https://doi.org/10.1007/s00170-021-06713-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06713-3