Abstract

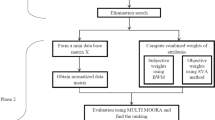

Motivated by a real-world material handling system selection problem, this paper proposes a framework that allows for quantifying safety and incorporating it in multi-criteria decision-making processes that involve both quantitative and qualitative measures. In the proposed framework, the results of failure mode and effect analysis (FMEA) for each alternative are converted into a quantitative measure of total safety and reliability associated with that alternative. A modified analytic hierarchy process (AHP) that differentiates between subjective and objective measures is then used to compare the alternatives at hand. In this modified AHP, experts’ judgments are used for pairwise comparison of alternatives with respect to qualitative measures, while for quantitative criteria, measured or estimated performance is directly used to obtain the required pairwise comparisons. An Excel-based decision support tool that implements the proposed framework is developed and made available online for researchers and practitioners. An application based on a real-world problem in an injection molding facility is also presented.

Similar content being viewed by others

References

Esmaeilian B, Behdad S, Wang B (2016) The evolution and future of manufacturing: a review. J Manuf Syst 39:79–100

Negahban A, Smith JS (2014) Simulation for manufacturing system design and operation: literature review and analysis. J Manuf Syst 33(2):241–261

Roodbergen KJ, Vis IFA (2009) A survey of literature on automated storage and retrieval systems. Eur J Oper Res 194(2):343–362

Burt CN, Caccetta L (2014) Equipment selection for surface mining: a review. Interfaces 44(2):143–162

Lau HYK, Zhao Y (2008) Integrated scheduling of handling equipment at automated container terminals. Int J Prod Econ 112(2):665–682

Onut S, Kara SS, Mert S (2009) Selecting the suitable material handling equipment in the presence of vagueness. Int J Adv Manuf Technol 44(7):818–828

Zaghdoud R, Collart-Dutilleul S, Ghedira K, Mesghouni K, Zidi K (2013) A multi-objective approach for assignment containers to AIVs in a container terminal. In: Proceedings of the IEEE International Conference on Systems, Man, and Cybernetics, pp 2460–2466

Mhalla A, Collart-Dutilleul S, Zhang H (2016) Robust control under uncertainty for seaport handling equipments. Transportation Research Procedia 14:203–212

Mhalla A, Benrejeb M, Zhang H (2016) Maintenance processes for container handling equipment using P-time petri nets. J Eng Res 4(4):99–112

Vis IFA (2006) Survey of research in the design and control of automated guided vehicle systems. Eur J Oper Res 170(3):677–709

Ozkok M (2013) Risk assessment in ship hull structure production using FMEA. J Mar Sci Technol 22(2):173–185

Ocampo JR, Hernandez-Matias JC, Vizan A (2017) A method for estimating the influence of advanced manufacturing tools on the manufacturing competitiveness of Maquiladoras in the apparel industry in Central America. Comput Ind 87:31–51

Mejjaouli S, Babiceanu RF (2014) Holonic condition monitoring and fault-recovery system for sustainable manufacturing enterprises. In: Borangiu T, Trentesaux D, Thomas A (eds) Service orientation in Holonic and Multi-Agent Manufacturing and Robotics. Springer International Publishing, pp 31–46

Kuo C-H, Huang H-P (2000) Failure modeling and process monitoring for flexible manufacturing systems using colored timed Petri nets. IEEE Trans Robot Autom 16(3):301–312

Shah LA, Etienne A, Siadat A, Vernadat F (2016) Decision-making in the manufacturing environment using a value-risk graph. J Intell Manuf 27(3):617–630

Chemweno P, Pintelon L, Van Horenbeek A, Muchiri P (2015) Development of a risk assessment selection methodology for asset maintenance decision making An analytic network process (ANP) approach. Int J Prod Econ 170:663–676

Almannai B, Greenough R, Kay J (2008) A decision support tool based on QFD and FMEA for the selection of manufacturing automation technologies. Robot Comput Integr Manuf 24(4):501–507

Stamatis DH (2003) Failure mode and effect analysis: FMEA from theory to execution, 2nd edn. ASQ Quality Press, Milwaukee

Sikich J (1998) Development and implementation of an automated wafer transport system. In: Proceedings of the IEEE/SEMI Advanced Semiconductor Manufacturing Conference and Workshop, pp 400–404

Shoults LW (2016) Implementation of design failure modes and effects analysis for hybrid vehicle systems. MS thesis, Virginia Polytechnic Institute and State University

Chakraborty S, Banik D (2006) Design of a material handling equipment selection model using analytic hierarchy process. Int J Adv Manuf Technol 28(11):1237–1245

Aktan HE, Tosun O (2013) An integrated fuzzy AHP – fuzzy TOPSIS approach for AS/RS selection. Int J Prod Qual Manag 11(2):228–245

Chan FTS, Ip RWL, Lau H (2001) Integration of expert system with analytic hierarchy process for the design of material handling equipment selection system. J Mater Process Technol 116(2):137–145

Chan FTS (2002) Design of material handling equipment selection system: an integration of expert system with analytic hierarchy process approach. Integr Manuf Syst 13(1):58–68

Braglia M, Gabbrielli R, Miconi D (2001) Material handling device selection in cellular manufacturing. J Multi-Criteria Decis Anal 10(6):303–315

Saaty TL (1980) The analytic hierarchy process. McGraw-Hill, New York

Weber SF (1993) A modified analytic hierarchy process for automated manufacturing decisions. Interfaces 23(4):75–84

Silvestri A, DeFelice F, Petrillo A (2012) Multi-criteria risk analysis to improve safety in manufacturing systems. Int J Prod Res 50(17):4806–4821

Meesariganda BR, Ishizaka A (2017) Mapping verbal AHP scale to numerical scale for cloud computing strategy selection. Appl Soft Comput 53:111–118

Yan R, Dunnett SJ, Jackson LM (2016) Reliability modelling of automated guided vehicles by fault tree analysis. In: Proceedings of the 5th Conference on Operational Research, pp 3–10

Azadeh A, Moghaddam M, Asadzadeh SM, Negahban A (2011) An integrated fuzzy simulation-fuzzy data envelopment analysis algorithm for job-shop layout optimization: the case of injection process with ambiguous data. Eur J Oper Res 214(3):768– 779

Negahban A (2018) Optimizing consistency improvement of positive reciprocal matrices with implications for monte carlo analytic hierarchy process. Comput Ind Eng 124:113–124

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hellmann, W., Marino, D., Megahed, M. et al. Human, AGV or AIV? An integrated framework for material handling system selection with real-world application in an injection molding facility. Int J Adv Manuf Technol 101, 815–824 (2019). https://doi.org/10.1007/s00170-018-2958-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2958-x