Abstract

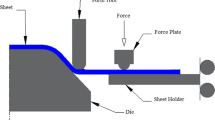

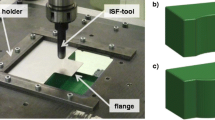

In this study, a new method is developed to reduce the variation of the wall thickness in incremental sheet forming method used in prototype production of sheet metal parts. Unlike the traditional incremental forming method, this new method defined as “rolling blank holder incremental forming method” is aimed primarily at the force optimization of the blank holder. In this context, 27 different experimental runs were carried out with 1 mm thick DC01 sheet metal. According to the experimental results, when 2 bar pressure was applied to the pneumatic clamps that supply the clamping force, 4.5% improvement of the minimum wall thickness was observed. Clearly, a better wall thickness distribution can be obtained when this new method is used, compared to the conventional incremental forming method.

Similar content being viewed by others

References

Tekkaya AE, Shankar R, Sebastiani G et al (2007) Surface reconstruction for incremental forming. Prod Eng 1:71–78. https://doi.org/10.1007/s11740-007-0024-x

Centeno G, Silva MB, Cristino VAM et al (2012) Hole-flanging by incremental sheet forming. Int J Mach Tools Manuf 59:46–54. https://doi.org/10.1016/j.ijmachtools.2012.03.007

Ndip-Agbor E, Smith J, Ren H et al (2016) Optimization of relative tool position in accumulative double sided incremental forming using finite element analysis and model bias correction. Int J Mater Form 9:371–382. https://doi.org/10.1007/s12289-014-1209-4

Malyer E (2013) The influence of toolpath strategy on geometric accuracy in incremental forming. Key Eng Mater 554–557:1351–1361. https://doi.org/10.4028/www.scientific.net/KEM.554-557.1351

Sbayti M, Ghiotti A, Bahloul R, et al. (2016) Finite element analysis of hot single point incremental forming of hip prostheses. MATEC web of conferences, NUMIFORM 2016 2.2

Lu B, Cao J, Ou H (2011) Theoretical and numerical analysis of incremental sheet forming by using high pressure water jet. ASME 2011 International Manufacturing Science and Engineering Conference, MSEC 2011. doi: https://doi.org/10.1115/MSEC2011-50235

Cao T, Lu B, Xu D et al (2015) An efficient method for thickness prediction in multi-pass incremental sheet forming. Int J Adv Manuf Technol 77:469–483. https://doi.org/10.1007/s00170-014-6489-9

Devarajan N, Sivaswamy G, Bhattacharya R et al (2014) Complex incremental sheet forming using back die support on aluminium 2024, 5083 and 7075 alloys. Procedia Eng 81:2298–2304. https://doi.org/10.1016/j.proeng.2014.10.324

Vanhove H, Mohammadi A, Duflou JR (2016) Incremental forming of aluminium alloys in cryogenic environment. AIP Conf Proc. https://doi.org/10.1063/1.4963473

Bouffioux C, Pouteau P, Duchêne L et al (2010) Material data identification to model the single point incremental forming process. Int J Mater Form 3:979–982. https://doi.org/10.1007/s12289-010-0933-7

Montanari L, Cristino VA, Silva MB, Martins PAF (2013) A new approach for deformation history of material elements in hole-flanging produced by single point incremental forming. Int J Adv Manuf Technol 69:1175–1183. https://doi.org/10.1007/s00170-013-5117-4

Hussain G, Gao L, Hayat N et al (2008) Tool and lubrication for negative incremental forming of a commercially pure titanium sheet. J Mater Process Technol 203:193–201. https://doi.org/10.1016/j.jmatprotec.2007.10.043

Zhang Q, Xiao F, Guo H et al (2010) Warm negative incremental forming of magnesium alloy AZ31 sheet: new lubricating method. J Mater Process Technol 210:323–329. https://doi.org/10.1016/j.jmatprotec.2009.09.018

Jackson KP, Allwood JM, Landert M (2008) Incremental forming of sandwich panels. J Mater Process Technol 204:290–303. https://doi.org/10.1016/j.jmatprotec.2007.11.117

de Sena JIV, Guzman CF, Duchene L et al (2016) Simulation of a two-slope pyramid made by SPIF using an adaptive remeshing method with solid-shell finite element. Int J Mater Form 9:383–394. https://doi.org/10.1007/s12289-014-1213-8

Liu ZB, Le Li Y, Bill WJT, Daniel PM (2014) Taguchi optimization of process parameters for forming time in incremental sheet forming process. Mater Sci Forum 773–774:137–143. https://doi.org/10.4028/www.scientific.net/MSF.773-774.137

Al-Ghamdi KA, Hussain G (2015) Threshold tool-radius condition maximizing the formability in SPIF considering a variety of materials: experimental and FE investigations. Int J Mach Tools Manuf 91:82–94. https://doi.org/10.1016/j.ijmachtools.2014.09.005

Kotcioglu I, Nasiri M, Cansiz A (2018) Heat transfer analysis of a rectangular channel having tubular router in different winglet configurations with Taguchi method. Appl Therm Eng 132:637–650. https://doi.org/10.1016/j.applthermaleng.2017.12.120

Singh G, Jain V, Gupta D, Ghai A (2016) Optimization of process parameters for drilled hole quality characteristics during cortical bone drilling using Taguchi method. J Mech Behav Biomed Mater 62:355–365. https://doi.org/10.1016/j.jmbbm.2016.05.015

Acknowledgements

The authors would like to thank Prof. Dr. Durmuş KARAYEL, Assoc. Prof. Dr. Mehmet ÇALIŞKAN, Assoc. Prof. Dr. Ergün NART, and Mr. Mahir YILDIRIM for their support and useful comments.

Funding

This work was financially supported by the Scientific Research Program, Sakarya University, Project No. 2016-09-06-002.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Seçgin, Ö., Özsert, İ. Experimental investigation of new blank holder approach for incremental forming method. Int J Adv Manuf Technol 101, 357–365 (2019). https://doi.org/10.1007/s00170-018-2880-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2880-2