Abstract

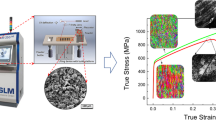

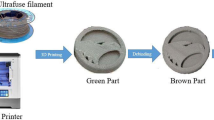

The joining capability of metal cellular structures fabricated using the additive manufacturing (selective laser melting (SLM)) method is investigated herein. The metal cellular structures are composed of sub-millimeter holes and internal pores. The direct joining of 3D-printed ABS-M30i thermoplastic parts to metal cellular structures by ultrasonic welding is demonstrated. The SLM-fabricated structures comprised of partially melted powders provide micro-scale roughness, which enhances the micro-mechanical interlocking between joining parts. A shear strength 17.7 MPa and normal tensile strength of 15.2 MPa were obtained, up to 55 and 48% of ABS-M30i ultimate tensile strength, respectively. Moreover, normal tensile plastic strength up to 86% of the shear strength was obtained.

Similar content being viewed by others

References

Kah P, Suoranta R, Martikainen J, Magnus C (2014) Techniques for joining dissimilar materials: metals and polymers. Rev Adv Mater Sci 36:152–164

Grujicic M, Sellappan V, Omar MA, Seyr N, Obieglo A, Erdmann M et al (2008) An overview of the polymer-to-metal direct-adhesion hybrid technologies for load-bearing automotive components. J Mater Process Technol 197:363–373

Yusof F, Miyashita Y, Seo N, Mutoh Y, Moshwan R (2012) Utilising friction spot joining for dissimilar joint between aluminium alloy (A5052) and polyethylene terephthalate. Sci Technol Weld Join 17:544–549

Fuchs AN, Wirth FX, Rinck P, Zaeh MF (2014) Laser-generated macroscopic and microscopic surface structures for the joining of aluminum and thermoplastics using friction press joining. Phys Procedia 56:801–810

Liu F, Liao J, Nakata K (2014) Joining of metal to plastic using friction lap welding. Mater Des 54:236–244

Katayama S, Kawahito Y (2008) Laser direct joining of metal and plastic. Scr Mater 59:1247–1250

Holtkamp J, Roesner A, Gillner A (2010) Advances in hybrid laser joining. Int J Adv Manuf Technol 47:923–930

Roesner A, Scheik S, Olowinsky A, Gillner A, Reisgen U, Schleser M (2011) Laser assisted joining of plastic metal hybrids. Phys Procedia 12:370–377

Heckert A, Zaeh MF (2015) Laser surface pre-treatment of aluminum for hybrid joints with glass fiber reinforced thermoplastics. J Laser Appl 27:S29005

Chen Y, Yue T, Guo Z (2016) A new laser joining technology for direct-bonding of metals and plastics. Mater Des 110:775–781

Byskov-Nielsen J, Boll JV, Holm AH, Højsholt R, Balling P (2010) Ultra-high-strength micro-mechanical interlocking by injection molding into laser-structured surfaces. Int J Adhes Adhes 30:485–488

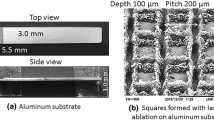

Yeh R-Y, Hsu R-Q (2016) Development of ultrasonic direct joining of thermoplastic to laser structured metal. Int J Adhes Adhes 65:28–32

CD Prest, D Weber (2011) Ultrasonic bonding of discrete plastic parts to metal, ed: Google patents

Bergmann JP, Stambke M (2012) Potential of laser-manufactured polymer-metal hybrid joints. Phys Procedia 39:84–91

Yusof F, Yukio M, Yoshiharu M, Abdul Shukor MH (2012) Effect of anodizing on pulsed Nd:YAG laser joining of polyethylene terephthalate (PET) and aluminium alloy (A5052). Mater Des 37:410–415

Engelmann C, Oster L, Olowinsky A, Gillner A, Mamuschkin V, Arntz D (2017) Novel process for butt-joined plastic-metal hybrid compounds. J Laser Appl 29:022416

Hopmann C, Kreimeier S, Keseberg J, Wenzlau C (2016) Joining of metal-plastics-hybrid structures using laser radiation by considering the surface structure of the metal. J Polym 2016:1–10

Abe F, Osakada K, Shiomi M, Uematsu K, Matsumoto M (2001) The manufacturing of hard tools from metallic powders by selective laser melting. J Mater Process Technol 111:210–213

Stratasys. http://tech-labs.com/sites/default/files/spec_sheets/FortusABSM30iMaterialSpecSheet-US-09-14.pdf

Roesner A, Scheik S, Olowinsky A, Gillner A, Poprawe R, Schleser M et al (2011) Innovative approach of joining hybrid components. J Laser Appl 23:032007

Acknowledgements

The authors gratefully acknowledge the support of the Ministry of Science and Technology for this research under grants MOST 105-2218-E-006-004 and MOST 105-2221-E-009-063.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, SH., Cheng, CW., Yeh, RY. et al. Direct joining of 3D-printed thermoplastic parts to SLM-fabricated metal cellular structures by ultrasonic welding. Int J Adv Manuf Technol 99, 729–736 (2018). https://doi.org/10.1007/s00170-018-2409-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2409-8