Abstract

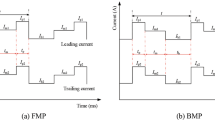

High-speed photography was used to record metal transfer during double-wire pulsed gas metal arc welding (GMAW) in the synchronous, alternating and independent phases, while the voltage and current waveforms were recorded simultaneously. According to the relationships between voltage, current, and metal transfer, the effect of phase on the behavior of metal transfer was analyzed. The experimental results demonstrated that metal transfer was all a “one drop per pulse” (ODPP) spray transfer mode in the three phases. ODPP was easier to achieve and metal transfer was more stable in the alternating phase. The deviation distance of droplets in the synchronous phase was larger than that in the alternating and independent phases, and the deviation distance of droplets in the alternating phase was minimum. The surfaces of weld beads acquired showed a desirable weld bead appearance that resembled fish scales. The weld bead in the alternating phase exhibited more obvious fish scales. Phase had little effect on weld width and reinforcement, though it had a significant effect on penetration. Penetration in the alternating phase was significantly deeper than penetration in the synchronous or independent phases, and penetration was minimum in the synchronous phase. The alternating phase facilitated the growth of columnar grains to be inhibited and the directions of ferrites to be disrupted. The columnar grains were discontinuous and the directions of ferrites were more chaotic in the alternating phase when compared with in the synchronous phase. And the anisotropic microstructure in the independent phase was between the synchronous and alternating phases.

Similar content being viewed by others

References

Trommer G (2009) Tandem wire process improves ship panel production. Weld J 88:42–45

Nadzam J (2003) Tandem GMAW offers quality weld deposits, high travel speeds. Weld Des Fabr 76:28–31

Lu Y, Chen SJ, Shi Y, Li XR, Chen JS, Kvidahl L, Zhang YM (2014) Double-electrode arc welding process: principle, variants, control and developments. J Manuf Process 16:93–108

Michie K, Blackman S, Ogunbiyi TEB (1999) Twin wire GMAW: process characteristics and applications. Weld J 78:31–34

Moinuddin SQ, Sharma A (2015) Arc stability and its impact on weld properties and microstructure in anti-phase synchronized synergic-pulsed twin-wire gas metal arc welding. Mater Des 67:293–302

Chen DS, Chen MA, Wu CS (2015) Effects of phase difference on the behavior of arc and weld pool in tandem P-GMAW. J Mater Process Technol 225:45–55

Yao P, Zhou K (2017) Research of a multi-frequency waveform control method on double-wire MIG arc welding. Appl Sci 7:171

Wu DS, Hua XM, Ye DJ, Ma XL, Li F (2017) Understanding of the weld pool convection in twin-wire GMAW process. Int J Adv Manuf Technol 88:219–227

Caimacan D, Mishchenko A, Scotti A (2017) Assessment of controlled short-circuiting application in filling passes with MIG/MAG double-wire process. Weld Int 31:90–99

Wu KY, He ZW, Liang ZY, Cheng J (2017) The dynamic behavior of double arc interference in high-power double wire pulsed GMAW. Int J Adv Manuf Technol 88:2795–2802

Iordachescu D, Quintino L (2008) Steps toward a new classification of metal transfer in gas metal arc welding. J Mater Process Technol 202:391–397

Scotti A, Ponomarev V, Lucas W (2014) Interchangeable metal transfer phenomenon in GMA welding: features, mechanisms, classification. J Mater Process Technol 214:2488–2496

Tipi ARD, Pariz N (2015) Improving the dynamic metal transfer model of gas metal arc welding (GMAW) process. Int J Adv Manuf Technol 76:657–668

Iordachescu D, Quintino L, Miranda R, Pimenta G (2006) Influence of shielding gases and process parameters on metal transfer and bead shape in MIG brazed joints of the thin zinc coated steel plates. Mater Des 27:381–390

Palani PK, Murugan N (2006) Selection of parameters of pulsed current gas metal arc welding. J Mater Process Technol 172:1–10

Reisgen U, Purrio M, Buchholz G, Willms K (2013) Possibilities of a control of the droplet detachment in pulsed gas metal arc welding. Weld World 57:701–706

Ghosh PK, Dorn L, Kulkarni S, Hofmann F (2009) Arc characteristics and behaviour of metal transfer in pulsed current GMA welding of stainless steel. J Mater Process Technol 209:1262–1274

Amin N (1983) Pulsed current parameters for arc stability and controlled metal transfer in arc welding. Met Constr 15:272–278

Wang QL, Li PJ (1997) Arc light sensing of droplet transfer and its analysis in pulsed GMAW process. Weld J 76:458–469

Zhang YM, Liguo E, Kovacevic R (1998) Active metal transfer control by monitoring excited droplet oscillation. Weld J 77:388–395

Chen MA, Wu CS, Li SK, Zhang YM (2007) Analysis of active control of metal transfer in modified pulsed GMAW. Sci Technol Weld Join 12:10–14

Han GM, Yun SH, Cao XH, Li JY (2003) Acquisition and pattern recognition of spectrum information of welding metal transfer. Mater Des 24:699–703

Pal K, Bhattacharya S, Pal SK (2010) Investigation on arc sound and metal transfer modes for on-line monitoring in pulsed gas metal arc welding. J Mater Process Technol 210:1397–1410

Luo Y, Zhu Y, Xie X, Xie XJ, Wan R (2016) Study on the transient impact energy of metal droplet transfer in P-MIG welding based on acoustic emission signals analysis. Mater Des 90:22–28

Huang Y, Zhang YM (2011) Laser enhanced metal transfer—part I: system and observations. Weld J 90:83–90

Huang Y, Zhang YM (2011) Laser-enhanced metal transfer–part II: analysis and influence factors. Weld J 90:205–210

Ding X, Li H, Yang LJ, Gao Y (2013) Numerical simulation of metal transfer process in tandem GMAW. Int J Adv Manuf Technol 69:107–112

Gu XY, Li H, Jiang XB, Sheng HC, Wan XM (2017) Effect of laser on droplet transfer and welding process stability in hybrid laser+ double arc welding. Int J Adv Manuf Technol 89:2981–2991

Groetelaars PJ, Morais CO, Scotti A (2009) Influence of the arc length on metal transfer in the single potential double-wire MIG/MAG process. Weld Int 23:112–119

Scotti A, Morais CO, Vilarinho LO (2006) The effect of out-of-phase pulsing on metal transfer in twin-wire GMA welding at high current level. Weld J 85:225–230

Ye DJ, Hua XM, Xu C, Li F, Wu YX (2017) Research on arc interference and welding operating point change of twin wire MIG welding. Int J Adv Manuf Technol 89:493–502

Funding

This work was supported by the National Natural Science Foundation of China (grant no. 51205136), the Competitive Allocation Project Special Fund of Guangdong Province Chinese Academy of Sciences Comprehensive Strategic Cooperation (grant no. 2013B091500082), the Fundamental Research Funds for the Central Universities (Key Program) (grant no. 2015ZZ084), the Science and Technology Planning Project of Guangzhou (grant no. 201604016015), and the China Scholarship Council (grant no. 201606155058).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, K., Yin, T., Ding, N. et al. Effect of phase on the behavior of metal transfer in double-wire pulsed GMAW. Int J Adv Manuf Technol 97, 3777–3789 (2018). https://doi.org/10.1007/s00170-018-2140-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2140-5