Abstract

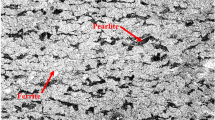

A novel triple-heat-source welding system including two pulsed MIG arcs and a laser beam entitled hybrid laser + double arc welding (HLDAW) is proposed in this study. Compared with hybrid laser + arc welding, the efficiency and gap tolerance are obviously improved. And meanwhile, hybrid laser + double arc welding can overcome problem of interference between the two arcs commonly encountered during double arc welding (DAW). This research is mainly focused on the underlying physical phenomena of the novel welding method especially the coupling mechanism of the three heat sources by exploiting high-speed imaging and welding electrical signals collecting, and the weld formation and microstructure were analyzed also. The obtained results point out that laser had obvious effect on droplet transfer and welding process stability. The short circuit frequency decreased and the stability of welding process was improved especially in high-speed welding after laser addition. Droplet transfer frequency was reduced and the diameter of droplet decreased in HLDAW compared with DAW. The weld appearance was improved significantly and weld penetration increased with the laser power. The welding speed improved by 25 % in HLDAW in comparison to DAW under the condition of obtaining the same penetration. HLDAW allows for the use of significantly higher welding velocities, acquires deeper penetrations, and obtains fine organization and more superior performance than possible with DAW alone.

Similar content being viewed by others

References

Lu Y, Chen SJ, Shi Y (2014) Double-electrode arc welding process: principle, variants, control and developments. J Manuf Process 16(1):93–108

Li KH, Zhang YM (2007) Metal transfer in double-electrode gas metal arc welding. J MANUF SCI E-T ASME 129(6):991–999

Li KH, Chen JS, Zhang YM (2007) Double-electrode GMAW process and control. Weld J 86(8):231–237

Li KH, Zhang YM (2010) Interval model control of consumable double-electrode gas metal arc welding process. IEEE T AUTOM SCI ENG 7(4):826–839

Matsumoto T, Sasabe S (2005) Tandem MIG welding of aluminum alloys. Weld Int 19(12):945–949

Li KH, Zhang YM (2008) Consumable double-electrode GMAW part 1: the process. Weld J 87:11s–17s

Ye DJ, Hua XM, Zhang J (2015) Analysis of arc interference and welding stability in twin wire GMA welding. Int J Adv Manuf Technol 81(1):627–633

Nayak SS, Biro E, Zhou Y (2015) Laser welding of advanced high-strength steels (AHSS). WELD JOI AHSS:71–92

Ribic B, Palmer TA, DebRoy T (2009) Problems and issues in laser-arc hybrid welding. Int Mater Rev 54:223–244

Chen YB, Feng JC, Li LQ (2013) Effects of welding positions on droplet transfer in CO2 laser-MAG hybrid welding. Int J Adv Manuf Technol 68:1351–1359

Xu GX, Wu CS, Qin GL, Wang XY (2011) Adaptive volumetric heat source models for laser beam and laser plus pulsed GMAW hybrid welding processes. Int J Adv Manuf Technol 57:245–255

Li CB, Liu LM (2013) Investigation on weldability of magnesium alloy thin sheet T-joints: arc welding, laser welding, and laser-arc hybrid welding. Int J Adv Manuf Technol 65(1):27–34

Liu LM, Yuan ST, Li CB (2012) Effect of relative location of laser beam and TIG arc in different hybrid welding modes. SCI TECHNOL WELD JOI 17:441–446

Zhao L, Sugino T, Arakane G, Tsukamoto S (2009) Influence of welding parameters on distribution of wire feeding elements in CO2 laser GMA hybrid welding. SCI TECHNOL WELD JOI 14:457–467

Zhang W, Hua XM, Liao W (2014) Behavior of the plasma characteristic and droplet transfer in CO2 laser-GMAW-P hybrid welding. Int J Adv Manuf Technol 72(5):935–942

Gu XY, Li H, Yang LJ, Gao Y (2013) Coupling mechanism of laser and arcs of laser-twin-arc hybrid welding and its effect on welding process. Opt Laser Technol 48:246–253

Gu XY, Li H, Yang LJ, Gao Y (2012) Influence of laser on arcs in alternate arcing during laser-twin-arc hybrid welding process. CHIN WELD 21(3):55–60

Gao ZG, Wu YX, Huang J (2009) Analysis of weld pool dynamic during stationary laser-MIG hybrid welding. Int J Adv Manuf Technol 44(9):870–879

Wei HL, Li H, Yang LJ, Gao Y, Ding XP (2015) Arc characteristics and metal transfer process of hybrid laser double GMA welding. Int J Adv Manuf Technol 77(5):1019–1028

NIST Atomic Spectra Database [DB/OL]. http://physics.nist.gov/PhysRefData/ ASD/lines_form.html.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gu, X., Li, H., Jiang, X. et al. Effect of laser on droplet transfer and welding process stability in hybrid laser + double arc welding. Int J Adv Manuf Technol 89, 2981–2991 (2017). https://doi.org/10.1007/s00170-016-9253-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9253-5