Abstract

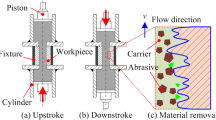

Surface roughness is one of the critical parameters that affect the component performance during its working life. To develop any process to its full potential, it is necessary to understand the physics of that process. Abrasive flow finishing (AFF) is one of the advanced finishing processes. In the current research work, an effort is made to understand physics and mechanism of surface roughness improvement during the AFF process. This research paper is divided into two sections. Firstly, the amount of finishing stresses and forces generated during the finishing of microholes fabricated on surgical stainless steel (316L) workpieces are computed by using the finite element method. Finishing stresses are generated in the viscoelastic medium. So, to compute finishing stresses, finite element analysis of the viscoelastic medium is carried out by incorporating its experimentally measured rheological properties. Finishing stresses are calculated along the circumferential direction of the microhole. Later, at the same workpiece surface location, simulated and experimentally measured surface roughness value are compared. Secondly, a new simulation model is proposed to predict the surface roughness on the microhole wall surface for various AFF input parameters. Maximum percentage change in surface roughness error of 8% is observed between simulated and experimental results after AFF process.

Similar content being viewed by others

References

Loveless TR, Williams RE, Rajurkar KP (1994) A study of the effects of abrasive-flow finishing on various machined surfaces. J Mater Process Technol 47(1–2):133–151

Raju HP, Narayanasamy K, Srinivasa YG, Krishnamurthy R (2005) Characteristics of extrude honed SG iron internal primitives. J Mater Process Technol 166(3):455–464

Sushil M, Vinod K, Harmesh K (2015) Experimental investigation and optimization of process parameters of Al/SiC MMCs finished by abrasive flow machining. Mater Manuf Process 30(7):902–911

Wu MY, Gao H (2016) Experimental study on large size bearing ring raceways’ precision polishing with abrasive flowing machine (AFM) method. Int J Adv Manuf Technol 83(9–12):1927–1935

Fu Y, Wang X, Gao H, Wei H, Li S (2016) Blade surface uniformity of blisk finished by abrasive flow machining. Int J Adv Manuf Technol 84(5–8):1725–1735

Walia RS, Shan HS, Kumar P (2009) Enhancing AFM process productivity through improved fixturing. Int J Adv Manuf Technol 44(7–8):700–709

Jain RK, Jain VK, Dixit PM (1999) Modeling of material removal and surface roughness in abrasive flow machining process. Int J Mach Tools Manuf 39(12):1903–1923

Jain RK, Jain VK (2003) Finite element simulation of abrasive flow machining. Proc Inst Mech Eng B J Eng Manuf 217(12):1723–1736

Jain RK, Jain VK (1999) Simulation of surface generated in abrasive flow machining process. Robot Comput Integr Manuf 15(5):403–412

Gorana VK, Jain VK, Lal GK (2006) Prediction of surface roughness during abrasive flow machining. Int J Adv Manuf Technol 31(3–4):258–267

Fang L, Sun K, Cen Q (2007) Particle movement patterns and their prediction in abrasive flow machining. Lubr Sci 13(4):195–206

Wang AC, Lung TS, Liang KZ, Chun-Ho LI, Shi-Hong WE (2009) Uniform surface polished method of complex holes in abrasive flow machining. Trans Nonferrous Metals Soc China 19:250–257

Wan S, Ang YJ, Sato T, Lim GC (2014) Process modeling and CFD simulation of two-way abrasive flow machining. Int J Adv Manuf Technol 71(5–8):1077–1086

Dash R, Maity K (2015) Simulation of abrasive flow machining process for 2D and 3D mixture models. Front Mech Eng 10(4):424–432

Chen KY, Cheng KC (2014) A study of helical passageways applied to polygon holes in abrasive flow machining. Int J Adv Manuf Technol 74(5–8):781–790

Wang AC, Cheng KC, Chen KY, Lin YC (2014) Enhancing the surface precision for the helical passageways in abrasive flow machining. Mater Manuf Process 29(2):153–159

Singh S, Raj AA, Sankar MR, Jain VK (2016) Finishing force analysis and simulation of nanosurface roughness in abrasive flow finishing process using medium rheological properties. Int J Adv Manuf Technol 85(9):2163–2178

Petri KL, Billo RE, Bidanda B (1998) A neural network process model for abrasive flow machining operations. J Manuf Syst 17(1):52–64

Mollah AA, Pratihar DK (2008) Modeling of TIG welding and abrasive flow machining processes using radial basis function networks. Int J Adv Manuf Technol 37(9):937–952

Hull JB, Fletcher AJ, Trengove SA, Mackie J (1992) Rheology of carrier media used in abrasive flow machining. Key Eng Mater 72:617–626

Davies PJ, Fletcher AJ (1995) The assessment of the rheological characteristics of various polyborosiloxane/grit mixtures as utilized in the abrasive flow machining process. Proc Inst Mech Eng C J Mech Eng Sci 209(6):409–418

Fletcher AJ, Fioravanti A (1996) Polishing and honing processes: an investigation of the thermal properties of mixtures of polyborosiloxane and silicon carbide abrasive. Proc Inst Mech Eng C J Mech Eng Sci 210(3):255–265

Sankar MR, Jain VK, Ramkumar J, Joshi YM (2011) Rheological characterization of styrene-butadiene based medium and its finishing performance using rotational abrasive flow finishing process. Int J Mach Tools Manuf 51(12):947–957

Kar KK, Ravikumar NL, Tailor PB, Ramkumar J, Sathiyamoorthy D (2009) Performance evaluation and rheological characterization of newly developed butyl rubber based media for abrasive flow machining process. J Mater Process Technol 209(4):2212–2221

Kar KK, Ravikumar NL, Tailor PB, Ramkumar J, Sathiyamoorthy D (2009) Preferential media for abrasive flow machining. J Manuf Sci Eng 131(1):1–11

Uhlmann E, Doits M, Schmiedel C (2013) Development of a material model for visco-elastic abrasive medium in abrasive flow machining. Proc CIRP 8:351–356

Uhlmann E, Schmiedel C, Wendler J (2015) CFD simulation of the abrasive flow machining process. Proc CIRP 31:209–214

Sankar MR, Ramkumar J, Jain VK (2009) Experimental investigation and mechanism of material removal in nano finishing of MMCs using abrasive flow finishing (AFF) process. Wear 266(7):688–698

Acknowledgements

The authors are thankful for the financial support provided by Board of Research in Nuclear Sciences (Project Number ME/P/MRS/02), Department of Science and Technology for their Technology Systems Development Program (DST/TSG/AMT/2015/619), and Defense Research Development & Development Laboratory (CARS Project).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, S., Kumar, D., Ravi Sankar, M. et al. Viscoelastic medium modeling and surface roughness simulation of microholes finished by abrasive flow finishing process. Int J Adv Manuf Technol 100, 1165–1182 (2019). https://doi.org/10.1007/s00170-018-1912-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1912-2