Abstract

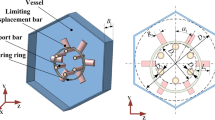

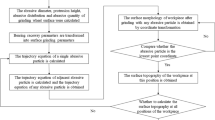

In some developing countries, the raceways of large bearing rings with outer diameters of 200 mm and above are ground and then are assembled and ready to leave the factory. While in the developed countries, they are superfinished with the high-frequency oscillation of whetstones, which is the only and conventional way and with a high cost. This paper presents a research on the precision polishing of large bearing ring raceways by an abrasive flow machine. This research adopts the ideas of forward design and reverse design in the design and manufacture of complex curved profile sections of the abrasive flow machine’s clamp and integrates the 3D scanning reverse and 3D printing technology into the design of the abrasive flow machine’s fixture, which reduce the bearing rings’ surface roughness from 0.4 μm after grinding to 0.1 μm after abrasive flow polishing, and change the surface microstructure and texture. This research provides new ideas and methods in bearing ring raceways’ superfinishing process and abrasive flow fixture design.

Similar content being viewed by others

References

Skurka JC (1970) Elastohydrodynamic lubrication of roller bearings. ASME J Lubr Technol 92:288–290

Castlfberry GA (1985) ‘Little things’ count in designing for contact stresses. Mach Des 57(18):75–78

Rhoades LJ (1987) AFM provides finishing touch for edges and surfaces. Cutting Tool Eng 39(2):53–53, 56

Rhoades LJ (1987) Abrasive flow machining with not-so-silly putty. Met Finish 85(7):27–29

Jain Rajendra K, Jain Vijay K, Dixit PM (1999) Modeling of materials removal and surface roughness in abrasive flow machining process. Int J Mach Tools Manuf 39(12):1903–1923

Rhoades L (1991) Abrasive flow machining: a case study. J Mater Process Technol 28(1-2):107–116

Song GZ (2010) Theoretical analysis and experimental research on abrasive flow machining. Dissertation, Taiyuan University of technology

Walia RS, Shan HS, Kumar P (2008) Determining dynamically active abrasive particles in the media used in centrifugal force assisted abrasive flow machining process. Int J Adv Manuf Technol 38(11-12):1157–1164

Sankar MR, Mondal S, Ramkumar J, Jain VK (2009) Experimental investigations and modeling of drill bit-guided abrasive flow finishing (DBG-AFF) process. Int J Adv Manuf Technol 42(7-8):678–688

Walia RS, Shan HS (2009) Enhancing AFM process productivity through improved fixturing. Int J Adv Manuf Technol 44(7-8):700–709

Gao H, Fu YZ, Zhu JH, Wu MY, Sun YW (2013) Study on the characteristics of new abrasive medium for abrasive flow machining. Adv Mater Res 797:417–422

Jain VK, Adsul SG (2000) Experimental investigations into abrasive flow machining(AFM). Int J Mach Tools Manuf 40(7):1003–1021

Walia RS, Shan HS, Kumar P (2009) Modeling of centrifugal-force-assisted abrasive flow machining. Proc Inst Mech Eng Part E: J Proc Mech Eng 223(4):195–204

Sankar MR, Jain VK, Ramkumar J (2009) Experimental investigations into rotating workpiece abrasive flow finishing. Wear 267(1-4):43–51

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, M.Y., Gao, H. Experimental study on large size bearing ring raceways’ precision polishing with abrasive flowing machine (AFM) method. Int J Adv Manuf Technol 83, 1927–1935 (2016). https://doi.org/10.1007/s00170-015-7706-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7706-x