Abstract

In the era of the short product life cycle, the return materials authorization (RMA) process plays an important role in satisfying customers because sellers have to prepare a certain amount of stock for returning products. Hence, determining how to evaluate the trade-off between over-stock and under-stock to balance cost-cutting and customer satisfaction is worthy of study. In this paper, we reveal a case taken from a leading TFT-LCD (thin film transistor liquid crystal display) maker in Taiwan, where the prepared stock is very likely to go from being hoarded to futility because the life cycle of TFT-LCD products is very short. To overcome the issues of the RMA process in the case company, obtaining the precise sizes of returning defectives in the near future is considered as one of the key tasks. General grey models (GMs) are widely applied to make predictions for this kind of short-term time series data; nevertheless, there still has the possibility of improving its predictions. This study thus proposes a new GM model, called the MTD-GM model, where a mega-trend-diffusion technique is employed to improve estimating the background values in the traditional GM. The experimental results show that the proposed MTD-GM grey model outperforms four other grey models with eight products in the case company data.

Similar content being viewed by others

References

Wu LF, Liu SF, Yao LG, Yan SL, Liu DL (2013) Grey system model with the fractional order accumulation. Commun Nonlinear Sci Numer Simul 18(7):1775–1785. https://doi.org/10.1016/j.cnsns.2012.11.017

Liu SF, Lin Y (2006) Grey information: theory and practical applications, 1st edn. Springer-Verlag, London, Britain

Pearman A (2016) Fifty shades of partial information. J. Grey Syst. 28(1):16–26

Boran FE (2015) Forecasting natural gas consumption in Turkey using grey prediction. Energy Sources Part B 10(2):208–213. https://doi.org/10.1080/15567249.2014.893040

Evans M (2014) An alternative approach to estimating the parameters of a generalised Grey Verhulst model: an application to steel intensity of use in the UK. Expert Syst Appl 41(4):1236–1244. https://doi.org/10.1016/j.eswa.2013.08.006

Li G-D, Masuda S, Nagai M (2013) An optimal prediction model for time series prediction in manufacturing systems. Int J Adv Manuf Technol 67(9–12):2343–2349. https://doi.org/10.1007/s00170-012-4654-6

Li G-D, Masuda S, Wang C-H, Yamaguchi D, Nagai M (2009) The hybrid grey-based model for cumulative curve prediction in manufacturing system. Int J Adv Manuf Technol 47(1–4):337–349. https://doi.org/10.1007/s00170-009-2199-0

Li G-D, Masuda S, Yamaguchi D, Nagai M, Wang C-H (2008) A study on the prediction of machining accuracy. Int J Adv Manuf Technol 43(5–6):529–537. https://doi.org/10.1007/s00170-008-1728-6

Li G-D, Yamaguchi D, Nagai M (2006) The development of stock exchange simulation prediction modeling by a hybrid grey dynamic model. Int J Adv Manuf Technol 36(1–2):195–204. https://doi.org/10.1007/s00170-006-0819-5

Rajesh R, Ravi V, Rao RV (2015) Selection of risk mitigation strategy in electronic supply chains using grey theory and digraph-matrix approaches. Int J Prod Res 53(1):238–257. https://doi.org/10.1080/00207543.2014.948579

Salmeron JL (2016) An autonomous FGCM-based system for surveillance assets coordination. J. Grey Syst 28(1):27–35

Tabaszewski M, Cempel C (2015) Using a set of GM(1,1) models to predict values of diagnostic symptoms. Mech Syst Signal Proc 52-53:416–425. https://doi.org/10.1016/j.ymssp.2014.08.013

Wang ZX, Hao P (2016) An improved grey multivariable model for predicting industrial energy consumption in China. Appl Math Model 40(11–12):5745–5758. https://doi.org/10.1016/j.apm.2016.01.012

Zeng B, Meng W, Tong MY (2016) A self-adaptive intelligence grey predictive model with alterable structure and its application. Eng Appl Artif Intell 50:236–244. https://doi.org/10.1016/j.engappai.2015.12.011

Deng JL (1982) Control problems of grey systems. Syst Control Lett 1(5):288–294

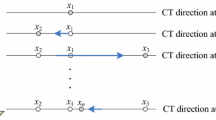

Xie NM, Liu SF (2009) Discrete grey forecasting model and its optimization. Appl Math Model 33(2):1173–1186

Yamaguchi D, Li GD, Nagai M (2007) A grey-based rough approximation model for interval data processing. Inform Sciences 177(21):4727–4744

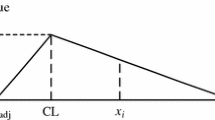

Li D-C, Wu C-S, Tsai T-I, Lina Y-S (2007) Using mega-trend-diffusion and artificial samples in small data set learning for early flexible manufacturing system scheduling knowledge. Comput Oper Res 34(4):966–982

Li DC, Yeh CW, Chang CJ (2009) An improved grey-based approach for early manufacturing data forecasting. Comput Ind Eng 57(4):1161–1167. https://doi.org/10.1016/j.cie.2009.05.005

Chang C-J, Li D-C, Huang Y-H, Chen C-C (2015) A novel gray forecasting model based on the box plot for small manufacturing data sets. Appl Math Comput 265:400–408. https://doi.org/10.1016/j.amc.2015.05.006

Huang C (1997) Principle of information diffusion. Fuzzy Sets Syst 91(1):69–90

Stojanovic V, Nedic N, Prsic D, Dubonjic L (2016) Optimal experiment design for identification of ARX models with constrained output in non-Gaussian noise. Appl Math Model 40(13–14):6676–6689. https://doi.org/10.1016/j.apm.2016.02.014

Stojanovic V, Filipovic V (2013) Adaptive input design for identification of output error model with constrained output. Circuits, Syst. Signal Process. 33(1):97–113. https://doi.org/10.1007/s00034-013-9633-0

Stojanovic V, Nedic N (2016) Identification of time-varying OE models in presence of non-Gaussian noise: application to pneumatic servo drives. Int J Robust Nonlinear Control 26(18):3974–3995. https://doi.org/10.1002/rnc.3544

Filipovic V, Nedic N, Stojanovic V (2011) Robust identification of pneumatic servo actuators in the real situations. Forsch Ingenieurwes 75(4):183–196. https://doi.org/10.1007/s10010-011-0144-5

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, DC., Yeh, CW., Chen, CC. et al. A new grey prediction model for the return material authorization process in the TFT-LCD industry. Int J Adv Manuf Technol 96, 2149–2160 (2018). https://doi.org/10.1007/s00170-018-1754-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1754-y