Abstract

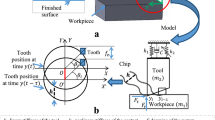

The surface forming mechanism is very important for material processing technology, which can directly influence the surface quality and processing efficiency. A new method for regulating and predicting the surface topography for ultrasonic vibration- assisted grinding (UAG) is presented in this paper. According to the kinematics analysis, the surface generating model is developed step by step in this study to control the surface micro structure and modify the machining parameters. The grinding force model and material removal rate model are also established for evaluating the UAG processing performance. Depend on the mathematical models, relationships between surface topography, grinding force, material removal rate, and ultrasonic vibration features can be revealed. Micro structure and high-precision surface can be design and manufactured through theoretical calculation. Due to the grain trajectory regulating, surface forming simulation was executed for verify the theory deduction. This model can be developing as a useful foundation for surface quality and machining efficiency improvement in UAG.

Similar content being viewed by others

References

Ding K, Fu YC, Su HH, Xu HX, Cui FF, Li QL (2017) Experimental studies on matching performance of grinding and vibration parameters in ultrasonic assisted grinding of SiC ceramics. Int Adv Manuf Technol 88:2527–2535

Wang Y, Lin B, Wang SL, Cao XX (2014) Study on the system matching of ultrasonic vibration assisted grinding for hard and brittle materials processing. Int J Mach Tools Manuf 77:66–73

Wang Y, Lin B, Zhang XF (2014) Research on the system matching model in ultrasonic vibration assisted grinding. Int J Adv Manuf Technol 70:449–458

Wang Y, Sarin VK, Lin B, Li H, Gillard S (2016) Feasibility study of the ultrasonic vibration filing of carbon fiber reinforced silicon carbide composites. Int J Mach Tools Manuf 101:10–17

Chen HF, Tang JY (2015) A model for prediction of surface roughness in ultrasonic-assisted grinding. Int Adv Manuf Technol 77(1):643–651

Zheng K, Li ZH, Liao WH, Xiao XZ (2016) Friction and wear performance on ultrasonic vibration assisted grinding dental zirconia ceramics against natural tooth. J Braz Soc Mech Sci 39(3):1–11

Qu W, Wang K, Miller MH, Huang Y, Chandra A (2000) Using vibration-assisted grinding to reduce subsurface damage. Precis Eng 24:329–337

Cao JG, Wu YB, Li JY, Zhang QJ (2015) A grinding force model for ultrasonic assisted internal grinding (UAIG) of SiC ceramics. Int Adv Manuf Technol 81(5):875–885

Li H, Lin B, Wan S, Wang Y, Zhang X (2016) An experimental investigation on ultrasonic vibration assisted grinding of SiO2f/SiO2 composites. Mater Manuf Process 31:887–895

Qin N, Pei ZJ, Treadwell C, Guo DM (2009) Physics-based predictive cutting force model in ultrasonic vibration assisted grinding for titanium drilling. J Manuf Sci Technol ASME 131:1–9

Wang Y, Lin B, Cao XX, Wang SL (2014) An experimental investigation of system matching in ultrasonic vibration assisted grinding for titanium. J Mater Process Technol 214(9):1871–1878

Spur G, Holl SE (1996) Ultrasonic assisted grinding of ceramics. J Mater Process Technol 62(4):287–293

Collins JA (1981) Failure of materials in mechanical design. Wiley, New York

Acknowledgements

The authors appreciate the supports from the open fund of the Tianjin Key Laboratory of Integrated Design and On-line Monitoring for Light Industry & Food Machinery and Equipment (grant no. 2016LIMFE03) and the National natural science foundation of China (grant no.51505334).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Fu, Z., Dong, Y. et al. Research on surface generating model in ultrasonic vibration-assisted grinding. Int J Adv Manuf Technol 96, 3429–3436 (2018). https://doi.org/10.1007/s00170-018-1744-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1744-0