Abstract

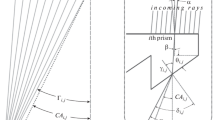

Fresnel lens arrays are widely applied as the core optical component in concentrated photovoltaic (CPV) systems for concentrating light on a solar cell. To improve the photoelectric conversion efficiency of CPV systems, a Fresnel lens design is proposed, in which both uniform concentration and machining feasibility are pursued by means of simpler structure. In this design, the concentrating facets of the Fresnel lens are conical ones with different inclined angles, and the light passing through these conical facets can be superposed on the same position. The optical performance of the lens is analyzed to optimize its geometrical parameters. Towards this uniform concentrating design with a simple structure, an ultra-precision diamond cutting process based on B axis rotation is also developed to machine the Fresnel lens mold. In this process, the V-shaped diamond tool is rotated from right to left to machine the micro grooves of the lens mold with a maximum cutting depth of the groove height, so that the grooves can be prevented from being cut by the tool tip with low strength. Cutting tests of the factors influencing the machining accuracy and surface quality are carried out to optimize the cutting trajectory planning and machining parameters. The Fresnel lens molds with no sharp corner defects and no surface scratches are machined, and dimensional accuracy of 1.0 μm and surface roughness of better than 13 nm are achieved. Then, a silicone rubber lens is cast based on this mold. Concentrating uniformity test of the lens is conducted, and a concentrating uniformity of better than 75% is achieved. The results show the effectiveness of the uniform concentrating design and the feasibility of the B axis rotating machining process.

Similar content being viewed by others

References

Xie WT, Dai YJ, Wang RZ, Sumathy K (2011) Concentrated solar energy applications using Fresnel lenses: a review. Renew Sust Energ Rev 15(6):2588–2606. https://doi.org/10.1016/j.rser.2011.03.031

Scanlon W (2014) NREL Demonstrates 45.7% Efficiency for Concentrator Solar Cell. NREL Official Website. http://www.nrel.gov/news/press/2014/15436. Accessed 16 Dec 2014

Garca I, Algora C, Stolle IR, Galiana B (2008) Study of non-uniform light profiles on high concentration III–V solar cells using quasi-3D distributed models. Proc 33rd IEEE Photovoltaic Specialist Conference: 1–6. https://doi.org/10.1109/PVSC.2008.4922908

Katz EA, Gordon JM, Feuermann D (2006) Effects of ultra-high flux and intensity distribution in multi-junction solar cells. Prog Photovolt Res Appl 14(4):297–303. https://doi.org/10.1002/pip.670

Victoria M, Domínguez C, Antón I, Sala G (2009) Comparative analysis of different secondary optical elements for aspheric primary lenses. Opt Express 17(8):6487–6492. https://doi.org/10.1364/OE.17.006487

Benítez P, Miñano JC, Zamora P, Mohedano R, Cvetkovic A, Buljan M, Chaves J, Hernández M (2010) High performance Fresnel-based photovoltaic concentrator. Opt Express 18(S1):A25–A40. https://doi.org/10.1364/OE.18.0000A25

Pan JW, Huang JY (2011) High concentration and homogenized Fresnel lens without secondary optics element. Opt Commun 284(19):4283–4288. https://doi.org/10.1016/j.optcom.2011.06.019

Wang G, Chen ZS, H P, Cheng XF, Mo SP, Jiang SL (2012) Research on strip-focus Fresnel solar concentrator with regular illumination. Acta energiae soaris sinica 5:1–7 (in Chinese)

Yan JW, Zhang ZY, Kuriyagawa T, Gonda H (2010) Fabricating micro-structured surface by using single-crystalline diamond endmill. Int J Adv Manuf Technol 51(9–12):957–964. https://doi.org/10.1007/s00170-010-2695-2

Brinksmeier E, Ralf G, Lars S (2012) Review on diamond-machining processes for the generation of functional surface structures. CIRP J Manuf Sci Technol 5(1):1–7. https://doi.org/10.1016/j.cirpj.2011.10.003

Yan JW, Maekawa K, Tamaki J, Kuriyagawa T (2005) Micro grooving on single-crystal germanium for infrared Fresnel lenses. J Micromech Microeng 15(10):1925–1931. https://doi.org/10.1088/0960-1317/15/10/019

Fan YF, Zhu YJ, Pan WQ (2010) Ultra-precision cutting of Fresnel lenses on single crystal germanium and the machining processing analysis. Proc SPIE 7655:207–208. https://doi.org/10.1117/12.866709

Allsop JL, Mateboera A, Shorea P (2011) Optimising efficiency in diamond turned Fresnel mould masters. Proc SPIE 8065:170–187. https://doi.org/10.1117/12.882925

Wang YL, Zhao QL, Shang YJ, Lv PX, Guo B, Zhao LL (2011) Ultra-precision machining of Fresnel microstructure on die steel using single crystal diamond tool. J Mater Process Technol 211(12):2152–2159. https://doi.org/10.1016/j.jmatprotec.2011.07.018

Duong CV, Li CJ, Li Y, Gao X (2014) Tool alignment on the B axis rotary table of an ultra-precision lathe machine. J Tsinghua Univ (Sci Technol) 54:1466–1470 (in Chinese). https://doi.org/10.16511/j.cnki.qhdxxb.2014.11.005

Li CJ, Li Y, Gao X, Duong CV (2015) Ultra-precision machining of Fresnel lens mould by single point diamond turning based on axis B rotation. Int J Adv Manuf Technol 77(5–8):907–913. https://doi.org/10.1007/s00170-014-6522-z

Davies MA, Evans CJ, Bergner BC (2003) Application of precision diamond machining to the manufacture of microphotonics components. Proc SPIE 5183:94–108. https://doi.org/10.1117/12.506373

Acknowledgements

We thank Wacker Chemicals (China) Co., Ltd. for providing the silicone rubber, and Shanghai Superhard Precision Tools Co., Ltd. for diamond tool customization service.

Funding

This research is supported by the Beijing Natural Science Foundation (No. 3131003, No. 3172013), Independent Research Project of the State Key Laboratory of Tribology at Tsinghua University (No. SKLT2013C01), and National Natural Science Foundation of China (No. 51675054).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, X., Li, Y., Kong, Q. et al. Uniform concentrating design and mold machining of Fresnel lens for photovoltaic systems. Int J Adv Manuf Technol 96, 451–460 (2018). https://doi.org/10.1007/s00170-018-1591-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1591-z