Abstract

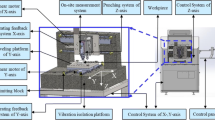

This paper presents design of a refractive-diffractive hybrid lens for use in micro optical scanning systems. To achieve the target focal length with minimized aberration, the refractive lens was optimally designed with consideration of reducing transverse ray aberration. The diffractive efficiency was calculated in terms of depth and period of the Fresnel pattern via rigorous coupled wave-analysis (RCWA). The geometry of the V-shaped diamond tools limits the depth of Fresnel edge of the diffractive lens due to the interference, which eventually determines the whole size of the lens. In this study, two types of hybrid lenses for micro scanning system were compared and designed in consideration of optical performance and machining limit. Therefore, the designed diffractive lens was optimized for 300 μm focal length with minimum aberration. The depth of Fresnel edge and the diameter was determined to be 0.94μm and 423.4μm within the machining limit, respectively. The lens base mold was fabricated using a 5-axis ultraprecision machine, and the lens was imprinted through a hot embossing process. The measured focal length and the calculated NA are 336μm and 0.63 respectively. Lastly, Imaging tests and diffractive efficiency are measured to evaluate the optical performance of the micro-hybrid lens.

Similar content being viewed by others

Abbreviations

- NA:

-

Numerical aperture

- Z(x):

-

Profile of the Fresnel lens

- Z0(x):

-

Original aspheric surface profile

- d :

-

Zone depth of Fresnel lens

- M:

-

Magnification

- l :

-

Object distance

- l’:

-

Image distance

References

Joo, J. Y. and Lee, S. K., “Miniaturized TIR Fresnel Lens For Miniature Optical Led Applications,” Int. J. Precis. Eng. Manuf., Vol. 10, No. 2, pp. 137–140, 2009.

Sweeney, D. W. and Sommargren, G. E., “Harmonic Diffractive Lenses,” Applied Optics, Vol. 34, No. 14, pp. 2469–2475, 1995.

Stone, T. and George, N., “Hybrid Diffractive-Refractive Lenses and Achromats,” Applied Optics, Vol. 27, No. 14, pp. 2960–2971, 1988.

Davidson, N., Friesem, A. A., and Hasman, E., “Analytic Design of Hybrid Diffractive-Refractive Achromats,” Applied Optics, Vol. 32, No. 25, pp. 4770–4774, 1993.

Fu, Y. Q. and Bryan, N. K. A., “Hybrid Microdiffractive-Microrefractive Lens with a Continuous Relief Fabricated by Use of Focused-Ion-Beam Milling for Single-Mode Fiber Coupling,” Applied Optics, Vol. 40, No. 32, pp. 5872–5876, 2001.

Woo, D. K., Hane, K., and Lee, S.-K., “Fabrication of a Multi-Level Lens using Independent-Exposure Lithography and FAB Plasma Etching,” Journal of Optics A: Pure and Applied Optics, Vol. 10, No. 4, Paper No. 044001, 2008.

Fujita, T., Nishihara, H., and Koyama, J., “Fabrication of Micro Lenses using Electron-Beam Lithography,” Optics Letters, Vol. 6, No. 12, pp. 613–615, 1981.

Blough, C. G., Rossi, M., Mack, S. K., and Michaels, R. L., “Single-Point Diamond Turning and Replication of Visible and Near-Infrared Diffractive Optical Elements,” Applied Optics, Vol. 36, No. 20, pp. 4648–4654, 1997.

Yan, J., Maekawa, K., Tamaki, J. I., and Kuriyagawa, T., “Micro Grooving on Single-Crystal Germanium for Infrared Fresnel Lenses,” Journal of Micromechanics and Microengineering, Vol. 15, No. 10, pp. 1925–1931, 2005.

Lee, H. S. and Park, J. R., “Experimental Study of Injection- Compression Molding of Film Insert Molded Plates,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 3, pp. 455–461, 2014.

Chen, S. T., Chang, K. E., Huang, W. P., Yang, H. Y., and Lee, X. M., “Development of A Cost-Effective High-Precision Bench Machine Tool for Multi-Level Micro Aspheric Lighting-Lens Mold Machining,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 12, pp. 2225–2231, 2012.

Smith, W. J., “Modern Lens Design,” McGraw-Hill, pp. 3–23, 2005.

Moharam, M. G. and Gaylord, T. K., “Rigorous Coupled-Wave Analysis of Planar-Grating Diffraction,” Journal of Optical Society of America, Vol. 71, No. 7, pp. 811–818, 1981.

Pramanik, A., Neo, K. S., Rahman, M., Li, X. P., Sawa, M., and Maeda, Y., “Cutting Performance of Diamond Tools during Ultra-Precision Turning of Electroless-Nickel Plated Die Materials,” Journal of Materials Processing Technology, Vol. 140, No. 1, pp. 308–313, 2003.

Becker, H. and Heim, U., “Hot Embossing as a Method for the Fabrication of Polymer High Aspect Ratio Structures,” Sensors and Actuators A: Physical, Vol. 83, No. 1, pp. 130–135, 2000.

Gale, M. T., Gimkiewicz, C., Obi, S., Schnieper, M., Söchtig, J., et al., “Replication Technology for Optical Microsystems,” Optics and Lasers in Engineering, Vol. 43, No. 3, pp. 373–386, 2005.

Lee, C., Kuriyagawa, T., Woo, D. K., and Lee, S. K., “Optimizing the Fabrication Process of a High-Efficiency Blazed Grating through Diamond Scribing and Molding,” Journal of Micromechanics and Microengineering, Vol. 20, No. 5, Paper No. 055028, 2010.

Buralli, D. A. and Morris, G. M., “Effects of Diffraction Efficiency on the Modulation Transfer Function of Diffractive Lenses,” Applied Optics, Vol. 31, No. 22, pp. 4389–4396, 1992.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yoo, DY., Lee, SK. & Lee, DH. Ultraprecision Machining-based Micro-Hybrid lens design for micro scanning devices. Int. J. Precis. Eng. Manuf. 16, 639–646 (2015). https://doi.org/10.1007/s12541-015-0085-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-015-0085-2