Abstract

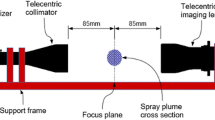

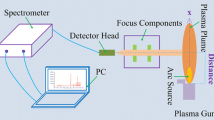

In this article, the feasibility study of application of the infrared camera for visualization of the particle jet in cold spray was performed. Stainless steel particles accelerated by the standard cold spray nozzle at spray parameters typical for cold spray deposition were used in experiments. Experimental results show that the infrared camera is capable to detect the particle trajectories due to significant temperature contrast and could be used as a robust technique for the powder trajectory visualization. Image treatment procedure allows to provide the particle jet profile at different distances from the nozzle exit. Obtained frames confirm the presence of particle collisions in the nozzle as well as in the free jet. Additional particle track velocimetry (PTV) measurements showed that the particle velocity in experiments was in the range 500–700 m/s that are the typical values for cold spraying of stainless steel powder.

Similar content being viewed by others

References

Papyrin A, Kosarev V, Klinkov S, Alkhimov A, Fomin V (2007) Cold spray technology. Elsevier Science, Amsterdam

Assadi H, Kreye H, Gartner F, Klassen T (2016) Cold spraying—a materials perspective. Acta Mater 116:382–407. https://doi.org/10.1016/j.actamat.2016.06.034

Vilafuerte J (2015) Modern cold spray: theory process and applications. Springer International Publishing, Switzerland. https://doi.org/10.1007/978-3-319-16772-5

Rokni MR, Widener CA, Champagne VK, Crawford GA, Nutt SR (January 2017) The effects of heat treatment on 7075 Al cold spray deposits. Surface and Coatings Technology, Volume 310(25):278–285. https://doi.org/10.1016/j.surfcoat.2016.10.064

Tao Y, Xiong T, Sun C, Kong L, Cui X, Li T, Song G-L (October 2010) Microstructure and corrosion performance of a cold sprayed aluminium coating on AZ91D magnesium alloy. Corros Sci 52(10):3191–3197. https://doi.org/10.1016/j.corsci.2010.05.023

(2007) Effect of substrate temperature on the formation mechanism of cold-sprayed aluminum, zinc and tin coatings, Effect of Substrate Temperature on the Formation Mechanism of Cold-Sprayed Aluminum, Zinc and Tin Coatings. J Thermal Spray Technol 16(5–6):619–626. https://doi.org/10.1007/s11666-007-9091-y

Wen-Ya Li, Chang-Jiu Li, Guan-Jun Yang, Effect of impact-induced melting on interface microstructure and bonding of cold-sprayed zinc coating, Applied Surface Science, Volume 257, Issue 5, 15 December 2010, Pages 1516–1523

Coddet P, Verdy C, Coddet C, Debray F, Lecouturier F (September 2015) Mechanical properties of thick 304L stainless steel deposits processed by He cold spray. Surface and Coatings Technology, Volume 277(15):74–80. https://doi.org/10.1016/j.surfcoat.2015.07.001

Sova A, Grigoriev S, Okunkova A, Smurov I (November 2013) Cold spray deposition of 316L stainless steel coatings on aluminium surface with following laser post-treatment. Surface and Coatings Technology, Volume 235(25):283–289. https://doi.org/10.1016/j.surfcoat.2013.07.052

Xian-ming MENG, Jun-bao ZHANG, Wei HAN, Jie ZHAO (2012) Fracture behavior of cold sprayed 304 stainless steel coating during cold rolling. J Iron Steel Res Int 19(11):57–63

Villa M, Dosta S, Guilemany JM (November 2013) Optimization of 316L stainless steel coatings on light alloys using cold gas spray. Surface and Coatings Technology 235(25):220–225. https://doi.org/10.1016/j.surfcoat.2013.07.036

Triantou KI, Pantelis DI, Guipont V, Jeandin M (August 2015) Microstructure and tribological behavior of copper and composite copper+alumina cold sprayed coatings for various alumina contents. Wear, Volumes 336–337(15):96–107

D. Seo, K. Ogawa, K. Sakaguchi, N. Miyamoto, Y. Tsuzuki, Parameter study influencing thermal conductivity of annealed pure copper coatings deposited by selective cold spray processes, surface and coatings technology, 206, 8–9, 15 January 2012, Pages 2316–2324

Kim D-Y, Park J-J, Lee J-G, Kim D, Tark SJ, Ahn S, Yun JH, Gwak J, Yoon KH, Chandra S, Yoon SS (2013) Cold spray deposition of copper electrodes on silicon and glass substrates. Journal of Thermal Spray Technology 22(7):1092–1102. https://doi.org/10.1007/s11666-013-9953-4

Hussain T, McCartney DG, Shipway PH, Marrocco T (2011) Corrosion behavior of cold sprayed titanium coatings and free standing deposits. Journal of Thermal Spray Technology 20(1–2):260–274. https://doi.org/10.1007/s11666-010-9540-x

Wong W, Vo P, Irissou E, Ryabinin AN, Legoux J-G, Yue S (2013) Effect of particle morphology and size distribution on cold-sprayed pure titanium coatings. Journal of Thermal Spray Technology 22(7):1140–1153. https://doi.org/10.1007/s11666-013-9951-6

Heli Koivuluoto, Giovanni Bolelli, Andrea Milanti, Luca Lusvarghi, Petri Vuoristo, Microstructural analysis of high-pressure cold-sprayed Ni, NiCu and NiCu + Al2O3 coatings, Surface and Coatings Technology 268, 25 April 2015, 224–229, DOI: https://doi.org/10.1016/j.surfcoat.2014.09.007

Wong W, Irissou E, Vo P, Sone M, Bernier F, Legoux J-G, Fukanuma H, Yue S (2013) Cold spray forming of Inconel 718. Journal of Thermal Spray Technology 22(2–3):413–421. https://doi.org/10.1007/s11666-012-9827-1

Harminder S, Sidhu TS, Karthikeyan J, Kalsi SBS (January 2015) Evaluation of characteristics and behavior of cold sprayed Ni–20Cr coating at elevated temperature in waste incinerator plant. Surface and Coatings Technology, Volume 261(15):375–384

P. Poza, C.J. Múnez, M.A. Garrido-Maneiro, S. Vezzù, S. Rech, A. Trentin, Mechanical properties of Inconel 625 cold-sprayed coatings after laser remelting. Depth sensing indentation analysis, Surface and Coatings Technology 243, 25 March 2014, Pages 51–57, DOI: https://doi.org/10.1016/j.surfcoat.2012.03.018

Toibah, A.R., Sato, M., Yamada, M., Fukumoto, M. Cold-sprayed TiO2 coatings from nanostructured ceramic agglomerated powders (2016) Materials and Manufacturing Processes, 31 (11), pp. 1527–1534, DOI: https://doi.org/10.1080/10426914.2015.1090587

Robotti M, Dosta S, Fernández-Rodríguez C, Hernández-Rodríguez MJ, Cano IG, Melián EP, Guilemany JM (2016) Photocatalytic abatement of NOx by C-TiO2/polymer composite coatings obtained by low pressure cold gas spraying. Applied Surface Science 362:274–280. https://doi.org/10.1016/j.apsusc.2015.11.207

Schmidt K, Buhl S, Davoudi N, Godard C, Merz R, Raid I, Kerscher E, Kopnarski M, Müller-Renno C, Ripperger S, Seewig J, Ziegler C, Antonyuk S (2016) Ti surface modification by cold spraying with TiO2 microparticles. Surface Coatings Technol 309:749–758. https://doi.org/10.1016/j.surfcoat.2016.10.091

H. AWAD, Samir; I. JADAAN, Riyam. STUDY THE OPTICAL PROPERTIES OF COPPER OXIDE THIN FILM DEPOSITED BY COLD SPRAY. Al-Qadisiyah J Eng Sci, [S.l.], v. 6, n. 4, p. 439–454, oct. 2017

Wei J, Zang Z, Zhang Y, Wang M, Du J, Tang X (2017) Enhanced performance of light-controlled conductive switching in hybrid cuprous oxide/reduced graphene oxide (Cu2O/rGO) nanocomposites. Opt Lett 42(5):911–914. https://doi.org/10.1364/OL.42.000911

Koivuluoto H, Vuoristo P (2010) Effect of powder type and composition on structure and mechanical properties of Cu + Al 2O 3 coatings prepared by using low-pressure cold spray process. J Therm Spray Technol 19(5):1081–1092. https://doi.org/10.1007/s11666-010-9491-2

Champagne V, Helfritch D (2008) Electromagnetic interface shielding by the cold spray particle deposition of an aluminium-alumina matrix. J Adv Mater 40(1):20–26

Wu X, Zhou X, Cui H, Zheng X, Zhang J (2012) Deposition behavior and characteristics of cold-sprayed Cu–Cr composite deposits. J Therm Spray Technol 21(5):792–799. https://doi.org/10.1007/s11666-012-9755-0

Maestracci R, Sova A, Jeandin M, J-M Malhaire I, Movchan P, Bertrand IS (2016) Deposition of composite coatings by cold spray using stainless steel 316L, copper and Tribaloy T-700 powder mixtures. Surf Coat Technol 287:1–8. https://doi.org/10.1016/j.surfcoat.2015.12.065

Katanoda H, Matsuoka T, Matsuo K (2007) Experimental study on shock wave structures in constant-area passage of cold spray nozzle. J Therm Sci 16(1):40–45. https://doi.org/10.1007/s11630-007-0040-3

Klinkov SV, Kosarev VF, Zaikovskii VN (2011) Influence of flow swirling and exit sFigure captionshape of barrel nozzle on cold spraying. J Therm Spray Technol 20(4):837–844. https://doi.org/10.1007/s11666-011-9621-5

Fukanuma H, Ohno N, Sun B, Huang R (2006) In-flight particle velocity measurements with DPV-2000 in cold spray. Surface and Coatings Technology 201(5):1935–1941. https://doi.org/10.1016/j.surfcoat.2006.04.035

Kuroda S, Molak RM, Watanabe M, Araki H, Katanoda H, Sun B, Ohno N, Fukanuma H (2013) Velocity measurement of sprayed particles and coatings fabrication of titanium alloys by high-pressure warm spray Proceedings of the International Thermal Spray Conference, pp. 263–268

Meyer MC, Yin S, McDonnell KA, Stier O, Lupoi R (October 2016) Feed rate effect on particulate acceleration in cold spray under low stagnation pressure conditions. Surface and Coatings Technology, Volume 304(25):237–245. https://doi.org/10.1016/j.surfcoat.2016.07.017

Jodoin B, Raletz F, Vardelle M (2006) Cold spray modeling and validation using an optical diagnostic method. Surface and Coatings Technology 200(14–15):4424–4432. https://doi.org/10.1016/j.surfcoat.2005.02.209

Zahiri SH, Yang W, Jahedi M (2009) Characterization of cold spray titanium supersonic jet. Journal of Thermal Spray Technology 18(1):110–117. https://doi.org/10.1007/s11666-008-9278-x

Sova A, Doubenskaia M, Grigoriev S, Okunkova A, Smurov I (2013) Parameters of the gas-powder supersonic jet in cold spraying using a mask. Journal of Thermal Spray Technology 22(4):551–556. https://doi.org/10.1007/s11666-013-9891-1

Sova A, Okunkova A, Grigoriev S, Smurov I (2013) Velocity of the particles accelerated by a cold spray micronozzle: experimental measurements and numerical simulation. J Therm Spray Technol 22(1):75–80. https://doi.org/10.1007/s11666-012-9846-y

Doubenskaia M, Novichenko D, Sova A, Pervoushin D (2010) Particle-in-flight monitoring in thermal spray processes. Surf Coat Technol 205(4):1092–1095. https://doi.org/10.1016/j.surfcoat.2010.07.075

Legoux JG, Irissou E, Moreau C (2007) Effect of substrate temperature on the formation mechanism of cold-sprayed aluminum, zinc and tin coatings. J Therm Spray Technol 16(5):619–626. https://doi.org/10.1007/s11666-007-9091-y

Sova, Alexey (2017): image2.avi. figshare, https://doi.org/10.6084/m9.figshare.5057098.v1

Acknowledgments

The work was carried out with financial support from the Ministry of Education and Science of the Russian Federation in the framework of Increase Competitiveness Program of NUST «MISiS» (№ К1-2016-030), implemented by the governmental decree dated on 16th of March 2013, N 211.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sova, A., Doubenskaia, M., Petrovskiy, P. et al. Visualization of particle jet in cold spray by infrared camera: feasibility tests. Int J Adv Manuf Technol 95, 3057–3063 (2018). https://doi.org/10.1007/s00170-017-1435-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1435-2