Abstract

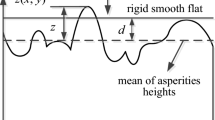

The effect of process parameters on surface roughening under simple tension in a tensile test is investigated. The assumption that the surface roughness is caused by the difference between the axial tensions of the top and bottom of the asperities in the thickness direction on the surface layer is used to model the free surface roughening. An equation is derived for the relationship between surface roughness and process parameters such as the initial roughness, effective strain, strain hardening exponent, and normal anisotropic value. In a tensile test, free surface roughness decreases nonlinearly as the normal anisotropic value and strain hardening exponent increase; it increases linearly with effective strain or grain size. Experimental results support the proposed model, which improves our understanding of the mechanism of the free surface roughening of sheet metals under tension.

Similar content being viewed by others

References

Kaga H (1971) Micro-geometric variation of surface profile in sheet metal forming. Ann CIRP 20(1):55–56

Thomson PF, Nayak PU (1980) The effect of plastic deformation on the roughening of free surfaces of sheet metal. Inst J Mach Des Res 20(4):73–86

Thomson PF, Shafer BV (1982) The roughening of a free surface during plastic working. Inst J Mach Des Res 22(4):261–264

Dautzenberg JH, Kals JAG (1984) Stress state and surface roughness, Advanced Technology of Plasticity I, the Japan Society for Technology of Plasticity, Tokyo, p 186–191

Dautzenberg JH, Kals JAG (1985) Surface roughness caused by metal forming. Ann CIRP 34(1):477–479. https://doi.org/10.1016/S0007-8506(07)61815-0

Klimczak T, Dautzenberg JH, Kals JAG (1988) On the roughening of a free surface during sheet metal forming. Ann CIRP 37(1):267–270. https://doi.org/10.1016/S0007-8506(07)61633-3

Chen G, Shen H, Hu S, Bernard B (1990) Roughening of the free surfaces of metallic sheets during stretch forming. Mater Sci Eng A 128(1):33–38

Dai YZ, Chiang FP (1992) On the mechanism of plastic deformation induced surface roughness. ASME J Eng Mater Technol 114(4):432–438. https://doi.org/10.1115/1.2904196

Mahmudi R, Mehdizadeh M (1998) Surface roughening during uniaxial and equi-biaxial stretching of 70-30 brass sheets. J Mater Process Technol 80-81:707–712. https://doi.org/10.1016/S0924-0136(98)00099-5

Wilson WRD, Lee W (2001) Mechanics of surface roughening in metal forming processes. ASME J Manuf Sci Eng 123(2):279–284. https://doi.org/10.1115/1.1363596

Leu DK (2010) Evaluation of friction coefficient using simplified deformation model of plastic hemispherical contact with a rigid flat. J Mech Sci Technol 24(8):1697–1707

Alexandrov S, Manabe KI, Furushima T (2011) A new empirical relation for free surface roughening. ASME J Manuf Sci Eng 133(1):014503 (5 pages)

Leu DK (2011) Evaluation of friction coefficient using indentation model of Brinell hardness test for sheet metal forming. J Mech Sci Technol 25(6):1509–1517

Leu DK (2011) Modeling of surface roughness effect on dry contact friction in metal forming. Int J Adv Manuf Technol 57(5-8):575–584. https://doi.org/10.1007/s00170-011-3305-7

Furushima T, Masuda T, Manabe KI, Alexandrov S (2012) Inhomogeneous 3D finite element model for prediction of free surface roughening. Adv Mater Res 418-420:1040–1043

Leu DK (2013) Effect of roughness geometry on friction during micro V-die bending by using finite element method. Int J Adv Manuf Technol 68(1-4):227–240. https://doi.org/10.1007/s00170-013-4723-5

Leu DK, Sheen SH (2013) Roughening of free surface during sheet metal forming. Trans ASME J Manuf Sci Eng 135(2):024502 (4 pages). https://doi.org/10.1115/1.4023713

Hill R (1950) The mathematical theory of plasticity. Oxford press, Oxford, pp 317–324

Yamagushi K, Mellor PB (1976) Thickness and grain size dependence of limit strains in sheet metal stretching. Int J Mach Sci 18(2):85–90. https://doi.org/10.1016/0020-7403(76)90055-2

Lubbinge H, ter Haar R, Schipper DJ (1996) The influence of plastic bulk deformation on surface roughness and frictional behavior during deep drawing processes. Tribology Series 31:705–711. https://doi.org/10.1016/S0167-8922(08)70832-0

Zhang K, Chen GN, Zhang K, Li HX (2008) Surface roughening of substrate of galvanized sheet induced by plastic deformation. J Plast Eng 15(6):1–3 (in Chinese)

Acknowledgments

The author would like to thank the Ministry of Science and Technology of the Republic of China, Taiwan, for financially supporting this research under Contract No. MOST 105-2221-E-149-002. The assistance of B.-Y. Chen and Y.-Y. Zhan with the experiment is appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Leu, DK. Free surface roughening under simple tension. Int J Adv Manuf Technol 95, 2349–2356 (2018). https://doi.org/10.1007/s00170-017-1418-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1418-3