Abstract

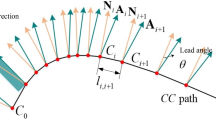

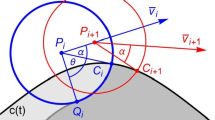

In a typical multi-pass machining process of freeform surfaces, especially at the roughing stage, the constant Z level strategy is typically used. Under this strategy, the inevitably formed islands where the tool has to travel between increase the machining time as the tool has to air-cut between them. Moreover, the uneven intermediate geometry left on the islands leads to sharp changing of chip load and jeopardizes the finish surface quality. To avoid the staircase-like intermediate geometry of the islands and most of all for the ultimate goal of maximizing the machining efficiency, in this paper we present a method of variable-depth of cut multi-pass tool path generation for multi-axis machining of mesh surfaces. By parameterizing the cut volume to a unit uvw cubic parametric domain, the multi-pass process planning task turns to finding an optimal sequence of w level parameters. To solve the optimization problem, we introduce a machining efficiency indicator—the average material removal rate (AMRR). The w level parameters are obtained by iteratively solving the maximization problem regarding AMRR. The preliminary computer simulation and real physical cutting experiments show that substantial savings in total machining time could be achieved by the proposed method as compared to the traditional constant Z level method.

Similar content being viewed by others

References

Tao S, Ting K-L (2001) Unified rough cutting tool path generation for sculptured surface machining. Int J Prod Res 39(13):2973–2989. https://doi.org/10.1080/00207540110052553

Elber G, Cohen E (1993) Tool path generation for freeform surface models. In: Proc. second ACM Symp. Solid model. Appl. ACM, New York, NY, USA, pp 419–428

He W, Lei M, Bin H (2009) Iso-parametric CNC tool path optimization based on adaptive grid generation. Int J Adv Manuf Technol 41(5-6):538–548. https://doi.org/10.1007/s00170-008-1500-y

Ding S, Mannan MA, Poo AN, Yang DCH, Han Z (2005) The implementation of adaptive isoplanar tool path generation for the machining of free-form surfaces. Int J Adv Manuf Technol 26(7-8):852–860. https://doi.org/10.1007/s00170-004-2058-y

Feng H-Y, Teng Z (2005) Iso-planar piecewise linear NC tool path generation from discrete measured data points. Comput Des 37:55–64

Hu P, Chen L, Tang K (2017) Efficiency-optimal iso-planar tool path generation for five-axis finishing machining of freeform surfaces. Comput Des 83:33–50. https://doi.org/10.1016/j.cad.2016.10.001

Oulee TH, Yang DCH, Chuang JJ (2004) Boundary conformed toolpath generation via Laplace based parametric redistribution method. J Manuf Sci Eng 126(2):345–354. https://doi.org/10.1115/1.1688373

Sun Y, Guo D, Jia Z, Wang H (2006) Iso-parametric tool path generation from triangular meshes for free-form surface machining. Int J Adv Manuf Technol 28:721–726

Sun Y, Ren F, Zhu X, Guo D (2012) Contour-parallel offset machining for trimmed surfaces based on conformal mapping with free boundary. Int J Adv Manuf Technol 60(1-4):261–271. https://doi.org/10.1007/s00170-011-3577-y

Hu P, Chen L, Wang J, Tang K (2015) Boundary-conformed tool path generation based on global reparametrization. In: 14th Int. Conf. Comput. Des. Comput Graph:165–172

Sun Y, Sun S, Xu J, Guo D (2017) A unified method of generating tool path based on multiple vector fields for CNC machining of compound NURBS surfaces. Comput Aided Des 91:14–26. https://doi.org/10.1016/j.cad.2017.04.003

Chen W, Xue J, Tang D, Chen H, Qu S (2009) Deformation prediction and error compensation in multilayer milling processes for thin-walled parts. Int J Mach Tools Manuf 49(11):859–864. https://doi.org/10.1016/j.ijmachtools.2009.05.006

Lefebvre PP, Lauwers B (2005) 3D morphing for generating intermediate roughing levels in multi-axis machining. Comput Aided Des Appl 2(1-4):115–123. https://doi.org/10.1080/16864360.2005.10738359

Huang B, Yang DCH (2006) A parametric implicit solid modeller based morphing technology for free-form surface machining. Int J Manuf Res 1(2):122–135. https://doi.org/10.1504/IJMR.2006.011349

Xu K, Tang K (2016) An energy saving approach for rough milling tool path planning. Comput Aided Des Appl 13(2):253–264. https://doi.org/10.1080/16864360.2015.1084198

Lee Y-S (1998) Non-isoparametric tool path planning by machining strip evaluation for 5-axis sculptured surface machining. Comput Des 30(7):559–570. https://doi.org/10.1016/S0010-4485(98)00822-7

Suresh K, Yang D (1994) Constant scallop-height machining of free-form surfaces. J Eng Ind 116(2):253–259. https://doi.org/10.1115/1.2901938

Chen L, Hu P, Luo M, Tang K (2017) Optimal interface surface determination for multi-axis freeform surface machining with both roughing and finishing. Chin J Aeronaut. https://doi.org/10.1016/J.CJA.2017.07.004

Xu K, Tang K (2014) Five-axis tool path and feed rate optimization based on the cutting force—area quotient potential field. Int J Adv Manuf Technol 75(9-12):1661–1679. https://doi.org/10.1007/s00170-014-6221-9

Engin S, Altintas Y (2001) Mechanics and dynamics of general milling cutters. Part II: Inserted cutters. Int J Mach Tools Manuf 41(15):2213–2231. https://doi.org/10.1016/S0890-6955(01)00046-3

Beudaert X, Pechard P-Y, Tournier C (2011) 5-Axis tool path smoothing based on drive constraints. Int J Mach Tools Manuf 51(12):958–965. https://doi.org/10.1016/j.ijmachtools.2011.08.014

Sencer B, Altintas Y, Croft E (2008) Feed optimization for five-axis CNC machine tools with drive constraints. Int J Mach Tools Manuf 48(7-8):733–745. https://doi.org/10.1016/j.ijmachtools.2008.01.002

Qian L, Yang B, Lei S (2008) Comparing and combining off-line feedrate rescheduling strategies in free-form surface machining with feedrate acceleration and deceleration. Robot Comput Integr Manuf 24(6):796–803. https://doi.org/10.1016/j.rcim.2008.03.015

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, L., Li, Y. & Tang, K. Variable-depth multi-pass tool path generation on mesh surfaces. Int J Adv Manuf Technol 95, 2169–2183 (2018). https://doi.org/10.1007/s00170-017-1367-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1367-x